Method for in-situ decentralized treatment of pig free-ranging manure liquid

A technology for decentralized treatment and live pigs, applied in water/sewage treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc. It can solve the problems of large investment, high operating costs, and large construction volume, and achieve low energy consumption and easy maintenance. , high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

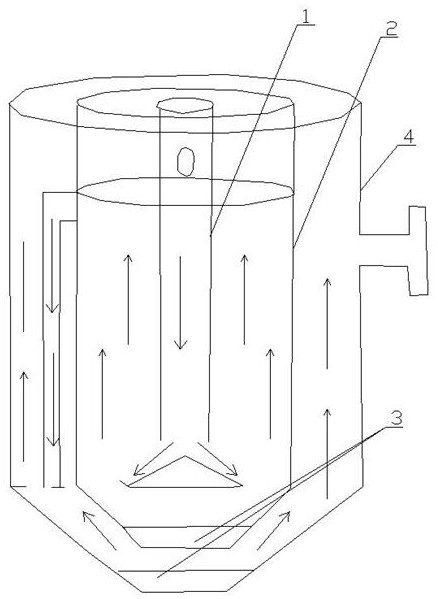

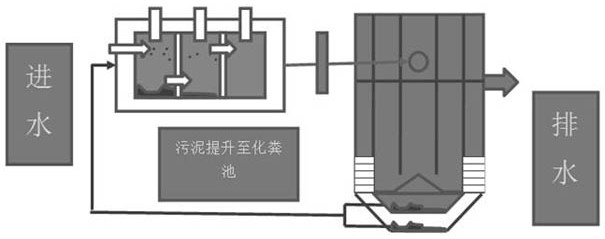

[0022] Embodiment 1: An integrated processor for water body purification and activation, including a pretreatment unit, a phosphorus removal main reaction unit and an advanced treatment unit.

[0023] The main reaction unit for phosphorus removal is equipped with non-consumable and non-chemical dosage type micro-electrochemical functional ceramsite materials.

[0024] The height of the water outlet of the pretreatment unit is higher than that of the phosphorus removal main reaction unit, and the water outlet of the phosphorus removal main reaction unit is higher than the water outlet of the advanced treatment unit. The main function is to remove suspended and colloidal substances in the water body through flocculation and sedimentation. No less than 150mm, to ensure the hydrostatic driving force of the self-flowing water body.

[0025] The bottoms of the pretreatment unit and the phosphorus removal main reaction unit are all provided with sludge discharge pipes.

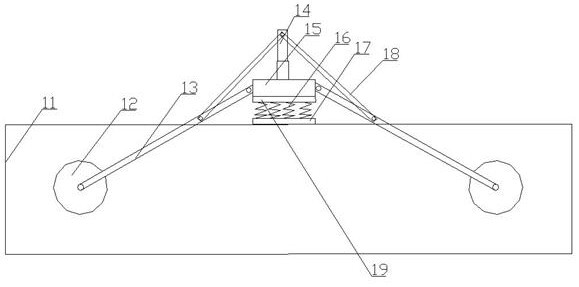

[0026] A m...

Embodiment 2

[0039] Embodiment 2: An integrated processor for water body purification and activation, including a pretreatment unit, a phosphorus removal main reaction unit and an advanced treatment unit.

[0040] The main reaction unit for phosphorus removal is equipped with non-consumable and non-chemical dosage type micro-electrochemical functional ceramsite materials.

[0041] The height of the water outlet of the pretreatment unit is higher than that of the phosphorus removal main reaction unit, and the water outlet of the phosphorus removal main reaction unit is higher than the water outlet of the advanced treatment unit. The main function is to remove suspended and colloidal substances in the water body through flocculation and sedimentation. No less than 150mm, to ensure the hydrostatic driving force of the self-flowing water body.

[0042] The bottoms of the pretreatment unit and the phosphorus removal main reaction unit are all provided with sludge discharge pipes.

[0043] A m...

Embodiment 3

[0053] Embodiment 3: An integrated processor for water body purification and activation, including a pretreatment unit, a phosphorus removal main reaction unit and an advanced treatment unit.

[0054] The main reaction unit for phosphorus removal is equipped with non-consumable and non-chemical dosage type micro-electrochemical functional ceramsite materials.

[0055] The height of the water outlet of the pretreatment unit is higher than that of the phosphorus removal main reaction unit, and the water outlet of the phosphorus removal main reaction unit is higher than the water outlet of the advanced treatment unit. The main function is to remove suspended and colloidal substances in the water body through flocculation and sedimentation. No less than 150mm, to ensure the hydrostatic driving force of the self-flowing water body.

[0056] The bottoms of the pretreatment unit and the phosphorus removal main reaction unit are all provided with sludge discharge pipes.

[0057] A m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com