A kind of chlorinated/epoxy fluorosilicone oil and its application in room temperature vulcanized fluorosilicone rubber

A fluorine-containing silicone oil and epoxy-based technology, applied in the field of fluorosilicone rubber, can solve problems such as slow curing speed, oil resistance, and single curing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

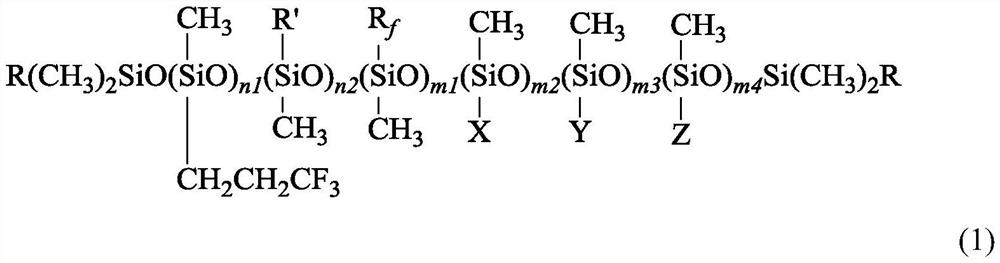

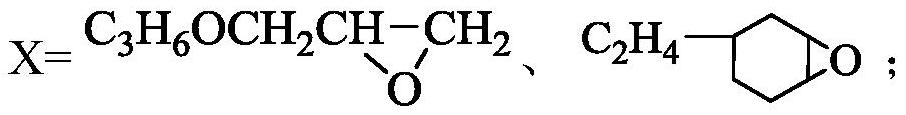

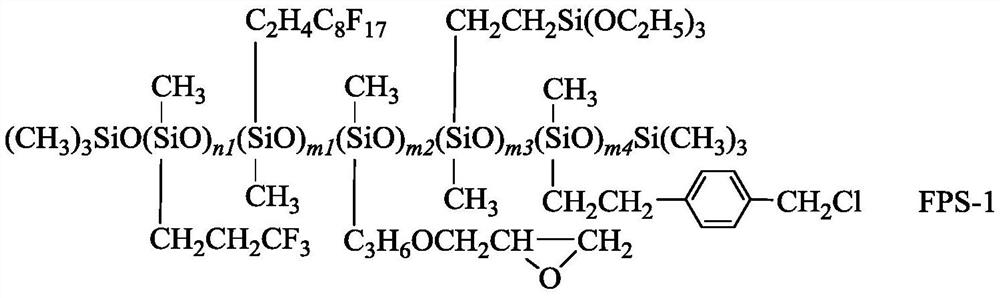

[0038] (1) Synthesis of chloro / epoxy fluorine-containing silicone oil FPS-1

[0039] In a three-necked flask equipped with a reflux condenser, a thermometer and a stirrer, 100 g of trimethylsilicon-terminated trifluoropropyl hydrogen-containing silicone oil with a Si-H content of about 0.3% and a viscosity of about 100 mPa.s was added in turn. (FPHMS-1, containing Si-H 0.3mol), 53.53g (0.12mol) heptadecafluoro-1-decene (R f17 Vi), 10.26g (0.09mol) allyl glycidyl ether AGE, 11.42g (0.06mol) vinyltriethoxysilane VTES, 4.57g (0.03mol) p-chloromethyl styrene, mechanically stir and mix, Heating to 80°C, adding 100ppm of complex platinum catalyst KP22, holding the reaction at 80°C for 10h, and then decompressing and boiling for 10min at an absolute pressure of 60mmHg and a temperature of 90°C, a total of about 179.78g of colorless, transparent-light Brown slightly turbid liquid, that is, the structure is shown in formula (1), n 2 =0, R = CH 3 , R f =-C 2 H 4 C 8 F 17 , X is ...

Embodiment 2

[0046] (1) Synthesis of chloro / epoxy fluorine-containing silicone oil FPS-2

[0047] In a three-necked flask equipped with a reflux condenser, a thermometer and a stirrer, 100 g of dimethyl hydrogen silicon-terminated poly(trifluoropropyl) with a Si-H content of about 0.05% and a viscosity of about 2000 mPa.s were added in turn. Methyl-co-methylhydrogensiloxane) FPHMS-2 (containing Si-H bond 0.05mol), 14.27g (0.0375mol) tridecafluoro-1-octene (R f13 Vi), 1.65g (0.005mol) Mn=300 allyl polyoxypropylene epoxy ether (AH307030), 0.82g (0.005mol) vinyltrimethoxysilane (VTMS), 0.29g (0.0025mol)2 -Chloroethyl vinyl ether, stir and mix well, heat up to 80°C, then add 500ppm of complex platinum catalyst KP22 and react at 85°C for 4h, the reaction is over, reduce the pressure under the conditions of an absolute pressure of 60mmHg and a temperature of 90°C De-boiling for 10min, a total of about 117.03g of colorless transparent-light brown slightly turbid liquid was obtained, that is, the...

Embodiment 3

[0054] (1) Synthesis of chloro / epoxy fluorine-containing silicone oil FPS-3

[0055] In a three-necked flask equipped with a reflux condenser, a thermometer and a stirrer, 100 g of trimethylsilicon-terminated poly(trifluoropropylmethyl) having a Si-H content of about 0.1% and a viscosity of about 1000 mPa.s was added in turn. Siloxane-co-methylhydrogen siloxane-co-dimethylsiloxane) copolymer (FPHMS-3, containing Si-H bond 0.1mol), 9.71g (0.05mol) pentafluorophenylethylene (R f Vi), 3.55g (0.025mol) glycidyl acrylate (AE), 2.29g (0.015mol) p-chloromethylstyrene, 2.48g (0.01mol) methacryloyloxypropyltrimethoxysilane (KH- 570), mechanically stirred and mixed, heated and heated to 80°C, then added 300ppm of complex platinum catalyst KP22 and reacted at 85°C for 6h, the reaction was completed, and the absolute pressure was 60mmHg and the temperature was 90°C under the conditions of decompression and low boiling for 10min, A total of 118.03g of colorless transparent-light brown sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com