Flexible heat protection coating, flexible heat protection coating for ethylene propylene rubber and preparation method thereof

An ethylene-propylene rubber, thermal protection technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of poor self-adhesion and mutual adhesion, difficult to combine thermal protection coatings, and increase surface adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

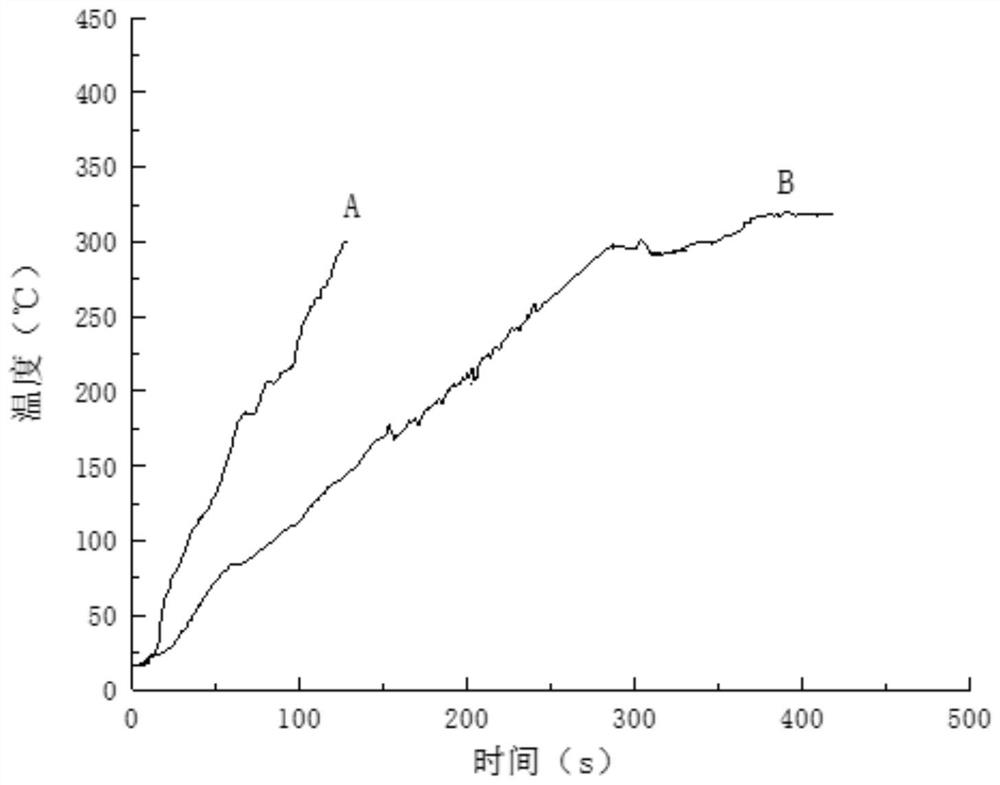

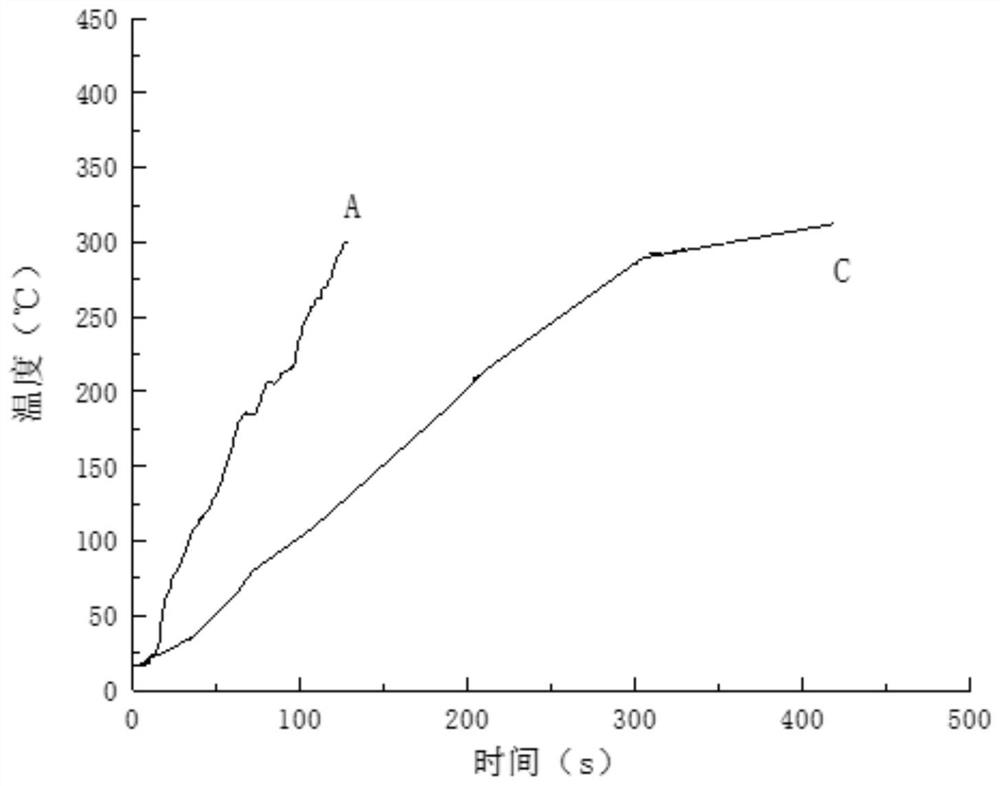

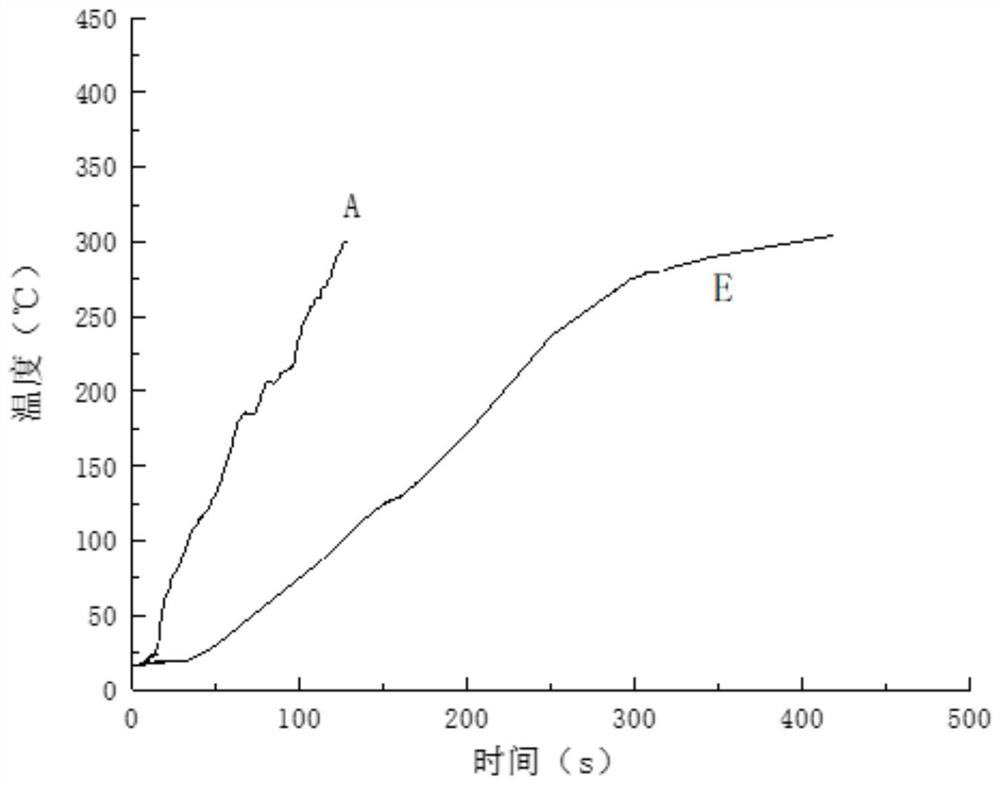

Image

Examples

Embodiment 1

[0040] First, the flexible thermal protective coating for ethylene-propylene rubber, its raw material ratio: 60g of methyl phenyl silicone rubber, 6g of methyl hydrogen silicone oil, 15g of hollow glass microspheres, 20g of 120# solvent (industrial heptane), orthosilicone 3 g of ethyl acetate, 0.5 g of dibutyl tin dilaurate, and 0.5 g of silane coupling agent. After mixing the film former, filler, organic solvent, and coupling agent, use a high-speed disperser to stir for 15-20 minutes at a speed of 1000r / min, then add a cross-linking agent and a catalyst, and stir quickly to obtain a flexible thermal protection coating.

[0041] The surface of the ethylene-propylene rubber is degreased, and the primer is brushed. The primer is composed of tetraethyl orthosilicate, γ-methacryloxypropyl trimethoxysilane and butadiene triethoxysilane according to the quality The ratio is 2:5:3 mixed preparation. Use the air spraying process to spray the required thickness of 1mm on the surface ...

Embodiment 2

[0043] First, the flexible thermal protective coating for ethylene-propylene rubber, its raw material ratio: 50g of methyl diphenyl silicone rubber, 10g of methyl hydrogen silicone oil, 25g of hollow glass microspheres, 25g of 120# solvent, 3.5 g, 0.3 g of dioctyltin diacetate, 0.5 g of silane coupling agent, and 2.5 g of mica powder. After mixing the film-forming material, filler, organic solvent, coupling agent and mica powder, use a high-speed disperser to stir for 15-20 minutes at a speed of 1000r / min, then add a cross-linking agent and a catalyst, and then stir quickly to obtain a flexible heat Protective coatings.

[0044] The surface of the ethylene-propylene rubber is degreased, and the primer is brushed. The primer is composed of tetraethyl orthosilicate, γ-methacryloxypropyl trimethoxysilane and butadiene triethoxysilane according to the quality The ratio is 2:5:3 mixed preparation. Spray 1mm on the surface of ethylene-propylene rubber by air spraying process, cure...

Embodiment 3

[0046] First, the flexible thermal protective coating for ethylene-propylene rubber, the raw material ratio: 50g of methyl phenyl silicone rubber, 15g of methyl hydrogen silicone oil, 20g of hollow glass microspheres, 30g of 120# solvent, 4.0g of ethyl orthosilicate , 0.5 g of dibutyltin diacetate, and 0.5 g of a titanate coupling agent. After mixing the film former, filler, organic solvent, and coupling agent, use a high-speed disperser to stir for 15-20 minutes at a speed of 1000r / min, then add a cross-linking agent and a catalyst, and stir quickly to obtain a flexible thermal protection coating.

[0047] The surface of the ethylene-propylene rubber is degreased, the primer is brushed, and the surface of the ethylene-propylene rubber is sprayed with an air spraying process of 1mm, and heated and cured at 120°C for 4 hours, and finally a flexible thermal protective coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com