Honeycomb three-dimensional integral woven structure type wave-absorbing composite material and preparation method thereof

A composite material and honeycomb technology, applied in shielding materials, magnetic/electric field shielding, electrical components, etc., can solve problems such as poor structural performance, easy cracking, and poor integrity, and achieve good wave-absorbing performance, reduced reflection, and integrity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A honeycomb three-dimensional overall woven structure wave-absorbing composite material is prepared by the following steps:

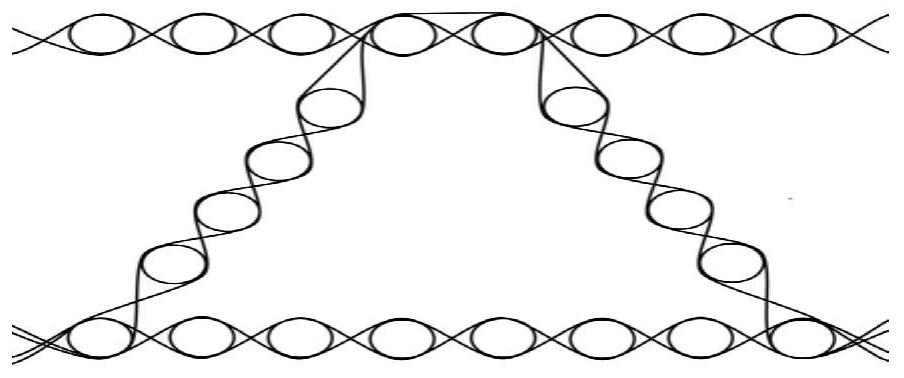

[0038] 1) According to the characteristics of the honeycomb three-dimensional woven fabric to be woven, adopt a reasonable organizational structure such as figure 1 As shown in the figure, design the pattern pattern and drafting pattern of the fabric, and select the reed number of 40 reed / 10cmd, use 240 pieces of 800tex basalt fiber filament yarn and 120 pieces of 800tex carbon fiber filament yarn, and weave the suction on the ordinary loom. The wave layer is a single-layer honeycomb three-dimensional woven fabric;

[0039] 2) the rigid polyurethane foam is cut into a strip-shaped triangular prism, and the cross-section at both ends is an isosceles triangle whose base length is 15 mm and height is 7 mm;

[0040] 3) filling the rigid polyurethane foam prepared in step 2) into the holes of the honeycomb three-dimensional woven fabric woven in step...

Embodiment 2

[0044]A honeycomb three-dimensional overall woven structure wave-absorbing composite material is prepared by the following steps:

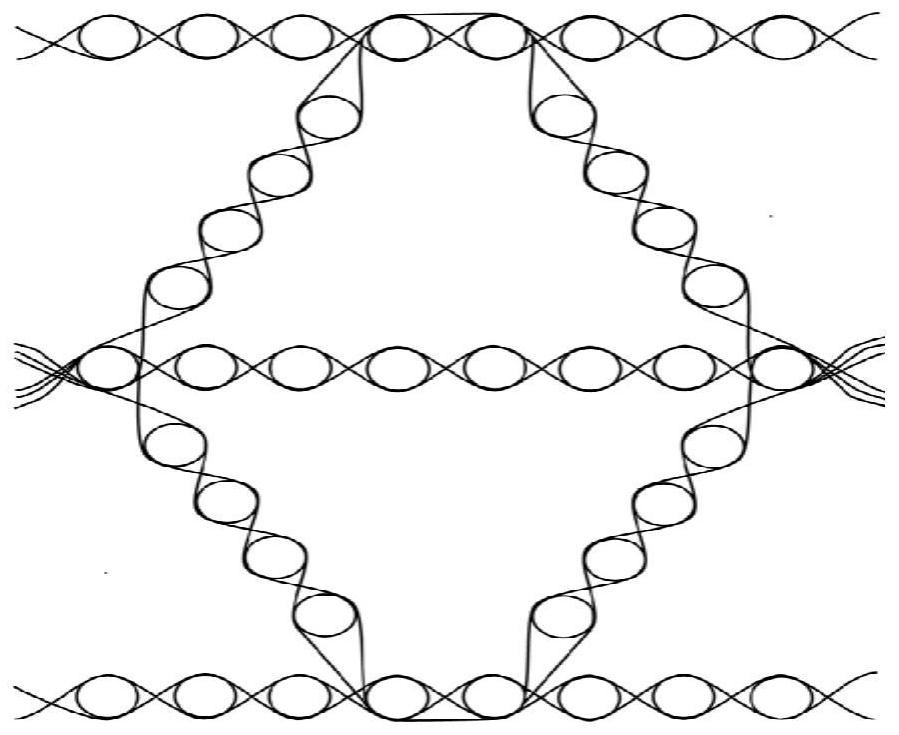

[0045] 1) According to the characteristics of the honeycomb three-dimensional woven fabric to be woven, adopt a reasonable organizational structure such as figure 2 As shown in the figure, design the pattern pattern and drafting pattern of the fabric, and select the reed number of 40 reed / 10cmd, use 480 pieces of 800tex basalt fiber filament yarn and 120 pieces of 800tex carbon fiber filament yarn, and weave the suction on the ordinary loom. Honeycomb three-dimensional woven fabric with two wave layers;

[0046] 2) the rigid polyurethane foam is cut into a strip-shaped triangular prism, and the cross-section at both ends is an isosceles triangle whose base length is 15 mm and height is 7 mm;

[0047] 3) filling the triangular rigid polyurethane foam prepared in step 2) into the holes of the honeycomb three-dimensional woven fabric woven in step ...

Embodiment 3

[0051] A honeycomb three-dimensional overall woven structure wave-absorbing composite material is prepared by the following steps:

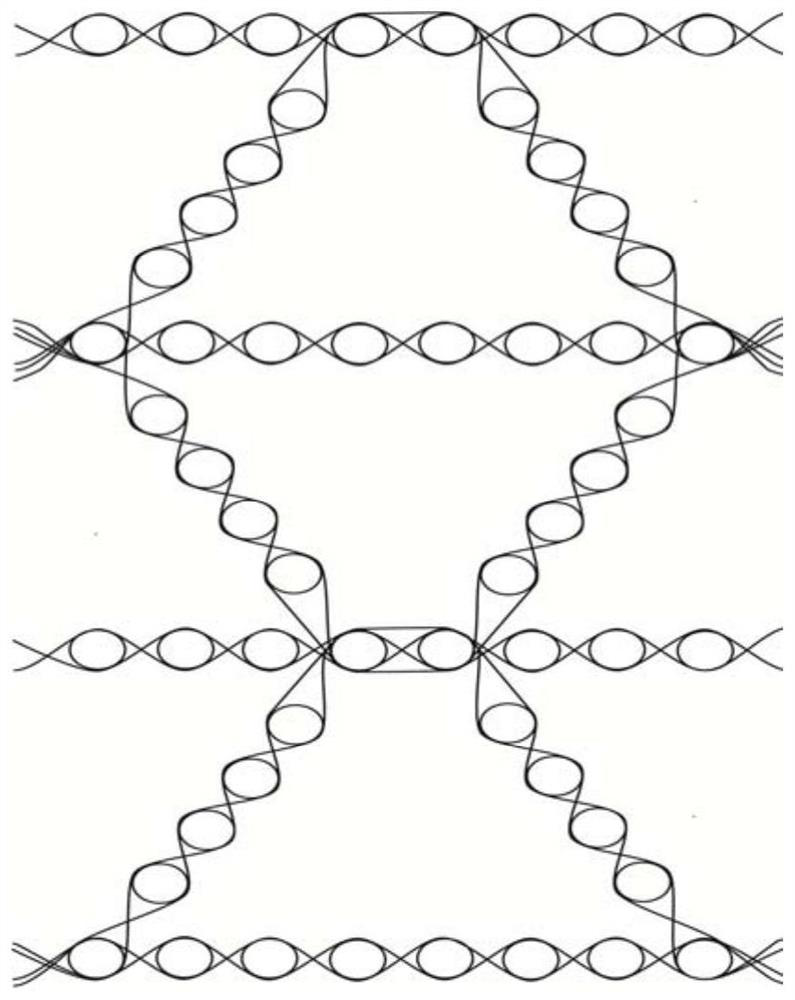

[0052] 1) According to the characteristics of the honeycomb three-dimensional woven fabric to be woven, adopt a reasonable organizational structure such as image 3 As shown in the figure, design the pattern pattern and drafting pattern of the fabric, and select the reed number of 40 reed / 10cmd, use 720 pieces of 800tex basalt fiber filament yarn and 120 pieces of 800tex carbon fiber filament yarn, and weave the suction on the ordinary loom. Honeycomb three-dimensional woven fabric with three wave layers;

[0053] 2) the rigid polyurethane foam is cut into a strip-shaped triangular prism, and the cross-section at both ends is an isosceles triangle whose base length is 15 mm and height is 7 mm;

[0054] 3) filling the triangular rigid polyurethane foam prepared in step 2) into the holes of the honeycomb three-dimensional woven fabric woven in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com