Preparation method of thin-wall large-scale soft microcapsule based on bubble method

A large-scale, microcapsule technology, applied in the field of biomedicine, can solve the problems of difficult regulation of capsule permeability, high concentration of nuclear residues, affecting the use of capsules, etc., and achieves the effects of short preparation time, simple equipment and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

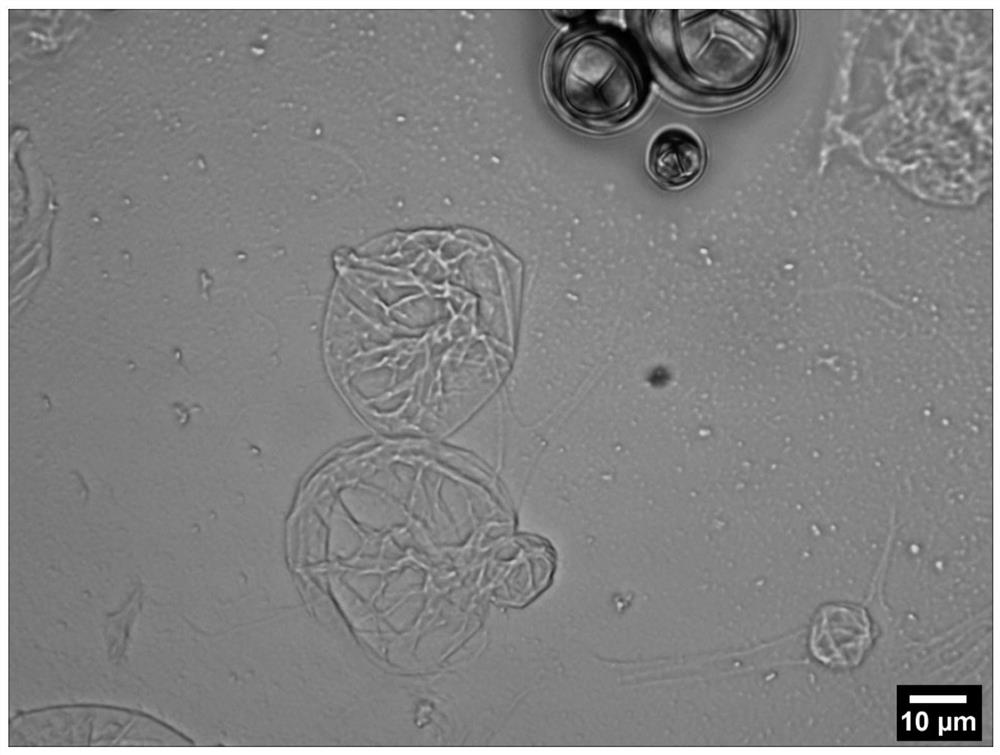

[0024] A method for preparing thin-walled large-scale soft microcapsules based on the bubble method, in which bovine serum albumin (BSA) microbubbles with negative charges on the surface are evenly dispersed in the solution, and polypropylene Hydroxylamine hydrochloride, polyallylamine hydrochloride solution and sodium polystyrene sulfonate polystyrene sulfonate solution are assembled layer by layer on the surface of microbubbles. Because the microbubbles are unstable, they dissolve slowly over time, leaving Thin-walled large-scale polymer soft microcapsules; comprising the steps of:

[0025] 1) After the bovine serum albumin solution and glucose are mixed uniformly in proportion, they are heated in a constant temperature water bath, and through the method of preparing bubbles (including ultrasonic method, syringe method and other methods for preparing microbubbles), the core component is air and Raw bovine serum albumin (BSA) microbubbles with negative charges on the surface;...

Embodiment 1

[0031] Mix bovine serum albumin solution and glucose evenly, heat in a constant temperature water bath, and ultrasonically treat with an ultrasonic cell disruptor to obtain microbubbles whose core component is air. Then disperse the microbubbles evenly, add positively charged polyallylamine hydrochloride solution, react for 2-3 minutes, the concentration of polyallylamine hydrochloride solution is 3mg / mL; centrifuge to remove the supernatant and use After washing with ion water several times (3-5 times), the centrifugation speed is 30-50RCF, and the centrifugation time is 1-2min. After immersing it in a negatively charged sodium polystyrene sulfonate solution for a period of time, the concentration of the sodium polystyrene sulfonate solution was 3 mg / mL. Similarly, soak for 2-3 minutes, then centrifuge to absorb the supernatant, the centrifugation speed and time are the same as above. Repeat the above process many times to obtain microbubbles that adsorb PAH and PSS layer by...

Embodiment 2

[0034] Mix bovine serum albumin solution and glucose evenly, heat in a constant temperature water bath, and ultrasonically treat with an ultrasonic cell disruptor to obtain microbubbles whose core component is air. Then disperse the microbubbles evenly, add positively charged polyallylamine hydrochloride solution, react for 2 to 3 minutes, the concentration of polyallylamine hydrochloride solution is 1mg / mL; centrifuge to remove the supernatant and use After washing with ion water several times (3-5 times), the centrifugation speed is 30-50RCF, and the centrifugation time is 1-2min. After immersing it in a negatively charged sodium polystyrene sulfonate solution for a period of time, the concentration of the sodium polystyrene sulfonate solution was 1 mg / mL. Similarly, soak for 2-3 minutes, then centrifuge to absorb the supernatant, the centrifugation speed and time are the same as above. Repeat the above process many times to obtain microbubbles that adsorb PAH and PSS layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com