Device and process for recovering carbon oxysulfide in chlorination process tail gas

A carbon oxysulfide and process tail gas technology, applied in the directions of carbon oxysulfide, carbon-sulfur compounds, steam condensation, etc., can solve the problems of increasing waste treatment costs, large solid waste and waste water, waste of carbon oxysulfide by-products, etc. The effect of high production value, reduction of raw material waste, and high degree of equipment integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

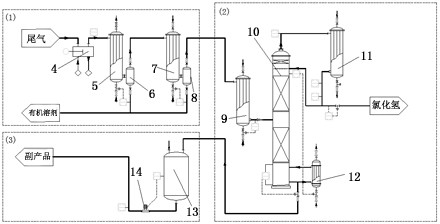

Embodiment 1

[0033] The invention recovers the carbon oxysulfide in the toluene-containing chlorination tail gas. The total flow rate of tail gas to be recovered is 100kg / h, wherein the mass fraction of carbon dioxide sulfide is 0.60, the mass fraction of hydrogen chloride is 0.38, and the mass fraction of toluene is 0.02. The outlet pressure of the tail gas compressor 4 is 2MPa, the refrigerant of the primary condenser 5 is circulating water, the refrigerant of the secondary condenser 7 is low-temperature water, and the refrigerant of the feed condenser 9 is -30°C cryogenic calcium chloride. The heating medium of the bottom reboiler 12 is 75°C hot water, and the cooling medium of the top condenser 11 is -30°C cryogenic calcium chloride. The recovered carbon oxysulfide flow rate is 48.87kg / h, the mass fraction is 0.992, and the recovery rate is 80.80%

Embodiment 2

[0035]The invention recovers the carbon oxysulfide in the ethanol-containing chlorination tail gas. The total flow rate of tail gas to be recovered is 100kg / h, in which the mass fraction of carbon oxysulfide is 0.55, the mass fraction of hydrogen chloride is 0.40, and the mass fraction of toluene is 0.05. The outlet pressure of exhaust compressor 4 is 2MPa, the refrigerant of primary condenser 5 is circulating water, the refrigerant of secondary condenser 7 is frozen ethylene glycol at -15°C, and the refrigerant of feed condenser 9 is cryogenic at -30°C Calcium chloride, the heating medium of the bottom reboiler 12 is 75°C hot water, and the cooling medium of the tower top condenser 11 is -30°C cryogenic calcium chloride. The flow rate of recovered carbon oxysulfide is 45.58kg / h, the mass fraction is 0.993, and the recovery rate is 82.29%.

Embodiment 3

[0037] The invention recovers the carbon oxysulfide in the chlorinated tail gas containing methylene chloride. The total flow rate of tail gas to be recovered is 100kg / h, wherein the mass fraction of carbon dioxide sulfide is 0.58, the mass fraction of hydrogen chloride is 0.39, and the mass fraction of toluene is 0.03. The outlet pressure of the tail gas compressor 4 is 2MPa, the refrigerant of the primary condenser 5 is low-temperature water, the refrigerant of the secondary condenser 7 is frozen ethylene glycol at -15°C, and the refrigerant of the feed condenser 9 is cryogenic at -30°C Calcium chloride, the heating medium of the bottom reboiler 12 is 75°C hot water, and the cooling medium of the tower top condenser 11 is -30°C cryogenic calcium chloride. The recovered carbon oxysulfide flow rate is 50.11kg / h, the mass fraction is 0.991, and the recovery rate is 85.62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com