Antibacterial purple sand and preparation method thereof

A technology of purple sand and antibacterial materials, applied in the field of purple sand, can solve the problems of no use value and low antibacterial rate, and achieve the effects of small deformation, good thermal shock resistance and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

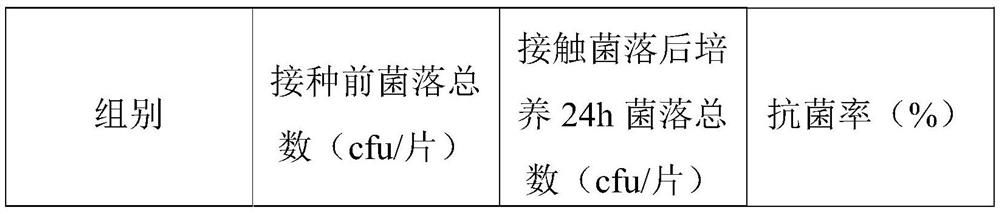

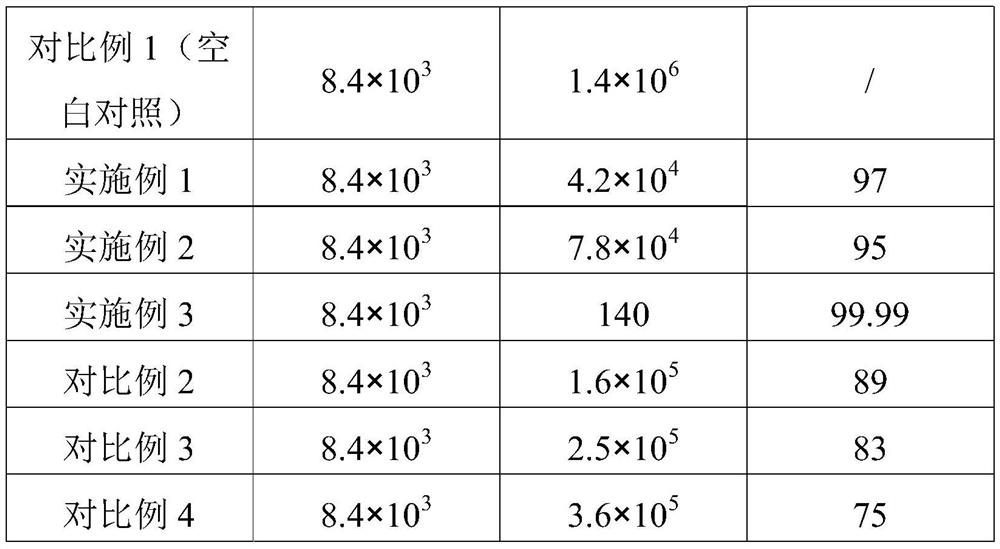

Examples

Embodiment 1

[0034] An antibacterial purple sand, comprising a purple sand base material and an antibacterial material, the antibacterial material is 8% of the purple sand base material, and the purple sand base material includes the following components by weight:

[0035] 60 parts of purple sand ore, 10 parts of laterite ore, 6 parts of black mud, 8 parts of purple wood knot and 4 parts of pyrophyllite;

[0036] The preparation method of described antibacterial material comprises the following steps:

[0037] (a) Take 40 parts by weight of tetraacicular zinc oxide and 75 parts by weight of ethylene glycol polyoxyethylene ether, add 580 parts by weight of deionized water, stir at a speed of 1800r / s for 30min until uniform, and obtain the first suspension;

[0038](b) Take 3 parts by weight of lanthanum oxide and 3 parts by weight of cerium oxide respectively, add them to 12 parts by weight of deionized water, then add concentrated nitric acid with a concentration of 95% until the solid is...

Embodiment 2

[0045] An antibacterial purple sand, comprising a purple sand base material and an antibacterial material, the antibacterial material is 10% of the purple sand base material;

[0046] The purple sand substrate includes the following components by weight:

[0047] 70 parts of purple sand ore, 15 parts of laterite ore, 10 parts of black mud, 12 parts of purple wood knot and 6 parts of pyrophyllite;

[0048] The preparation method of described antibacterial material comprises the following steps:

[0049] (a) Take 50 parts by weight of tetraacicular zinc oxide and 90 parts by weight of ethylene glycol polyoxyethylene ether, add 620 parts by weight of deionized water, stir at a speed of 2200r / s for 5min until uniform, and obtain the first suspension;

[0050] (b) Take 6 parts by weight of lanthanum oxide and 6 parts by weight of cerium oxide respectively, add them to 48 parts by weight of deionized water, then add concentrated nitric acid with a concentration of 95% until the sol...

Embodiment 3

[0057] An antibacterial purple sand, comprising a purple sand base material and an antibacterial material, the antibacterial material is 9% of the purple sand base material, and the purple sand base material includes the following components by weight:

[0058] 65 parts of purple sand ore, 12 parts of laterite ore, 8 parts of black mud, 10 parts of purple wood knot and 5 parts of pyrophyllite;

[0059] The preparation method of described antibacterial material comprises the following steps:

[0060] (a) Take 45 parts by weight of tetraacicular zinc oxide and 80 parts by weight of ethylene glycol polyoxyethylene ether, add 600 parts by weight of deionized water, stir at a speed of 2000r / s for 10min until uniform, and obtain the first suspension;

[0061] (b) Take 5 parts by weight of lanthanum oxide and 5 parts by weight of cerium oxide respectively, add them to 20 parts by weight of deionized water, then add concentrated nitric acid with a concentration of 95% until the solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com