Chiral self-contained microporous polymer as well as preparation method and application thereof

A microporous polymer, polymer technology, applied in separation methods, chemical instruments and methods, luminescent materials, etc., can solve problems such as no literature reports, and achieve the effects of simple operation, mild conditions, and strong fluorescence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

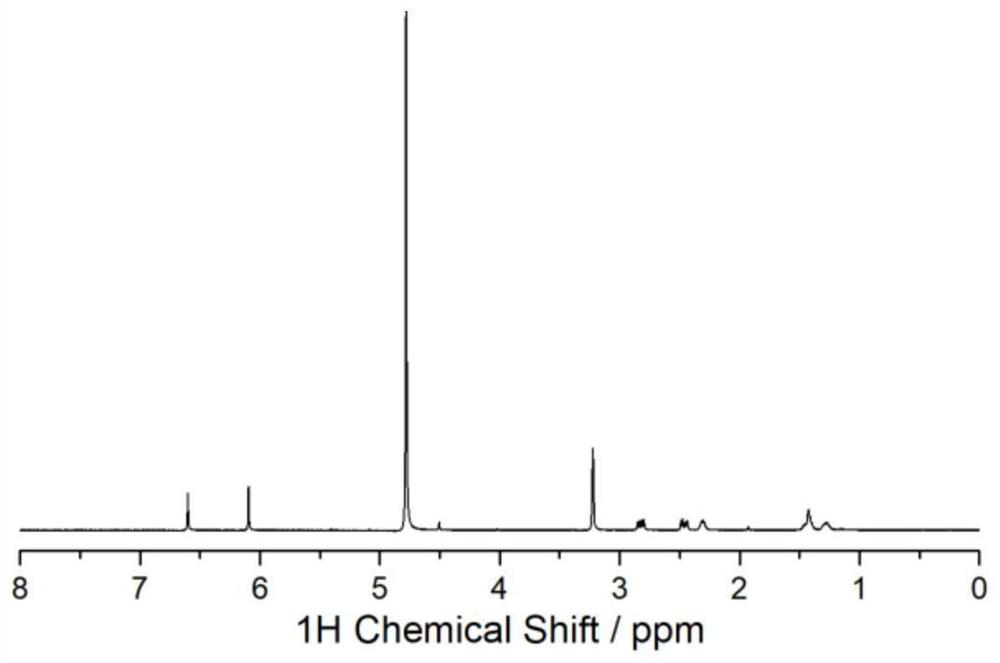

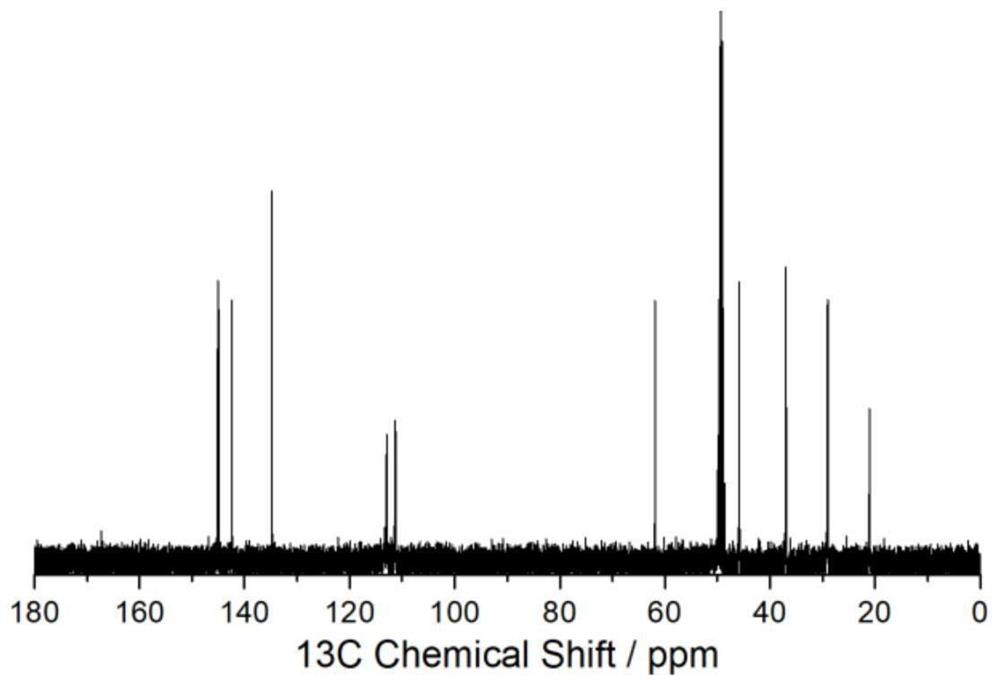

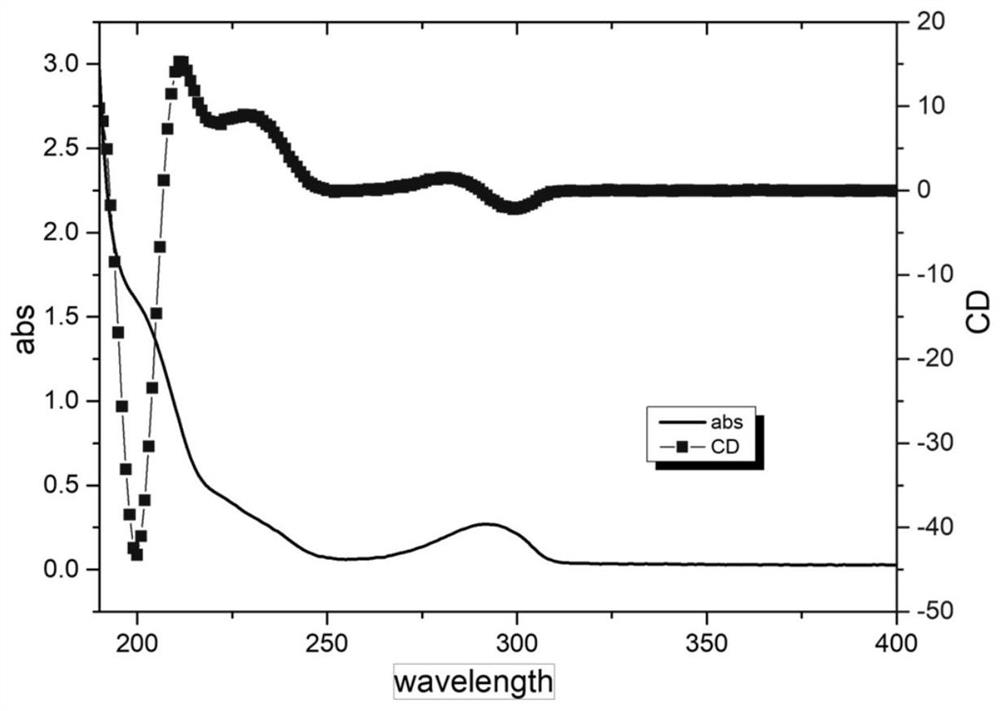

Image

Examples

Embodiment 1

[0044] (1) Preparation of polymer monomers

[0045]

[0046] For the preparation of compound 1, please refer to the preparation of compound 3i in the literature J.Am.Chem.Soc.2018, 140, 10374-10381, with an optical purity of 96% ee.

[0047] The preparation steps of compound 2 are as follows: add 10 mmol of dry powder of compound 1 to a 1L glass flask, and pass through nitrogen protection, add 200 ml of dry dichloromethane, stir to completely dissolve compound 1, and then put the reaction bottle into an ice-water bath to cool to 0°C, add BBr dropwise to the reaction flask 3 Dichloromethane solution (4M, 15ml, 60mmol), the system was gradually warmed to room temperature, and stirred at room temperature for 12 hours, then slowly added 200ml of water to the system to quench the reaction. The liquid was separated by a separatory funnel, and the aqueous phase and some insoluble solids were extracted with a large amount of dichloromethane to separate the phases. The combined dic...

Embodiment 2

[0057] (1) The preparation of the polymer monomer was carried out according to Example 1.

[0058] (2) Preparation of chiral soluble chain self-polymerized microporous polymer:

[0059] Under the protection of nitrogen atmosphere, compound 2 (0.01mol), tetrafluoroterephthalonitrile TFTPN (0.01mol) and dry potassium carbonate particles (0.030mol) were added to a three-necked flask, and N,N-dimethylacetamide was added In a mixed solvent of (DMAc) 18ml and toluene 4ml, stir and react at a constant temperature of 180°C for 4 hours, remove the heating and wait for the system to cool down to room temperature, pour the reaction solution into methanol, and filter with suction to obtain a bright yellow powder precipitate, followed by Wash with methanol and distilled water for 5 times, and dry overnight at 130° C. under vacuum to obtain a yellow fluorescent product polymer powder.

[0060] (3) Preparation of chiral separation membrane, carried out in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com