Rapid preparation method of screen printing paste for dye-sensitized solar cell photoanode

A solar cell and screen printing technology, applied in photosensitive equipment, cable/conductor manufacturing, circuits, etc., can solve the problems of complex preparation process, inability to prepare high-quality, unsuitable for industrial production, etc., and achieve simple preparation steps and film-making. Uniformity without cracking and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

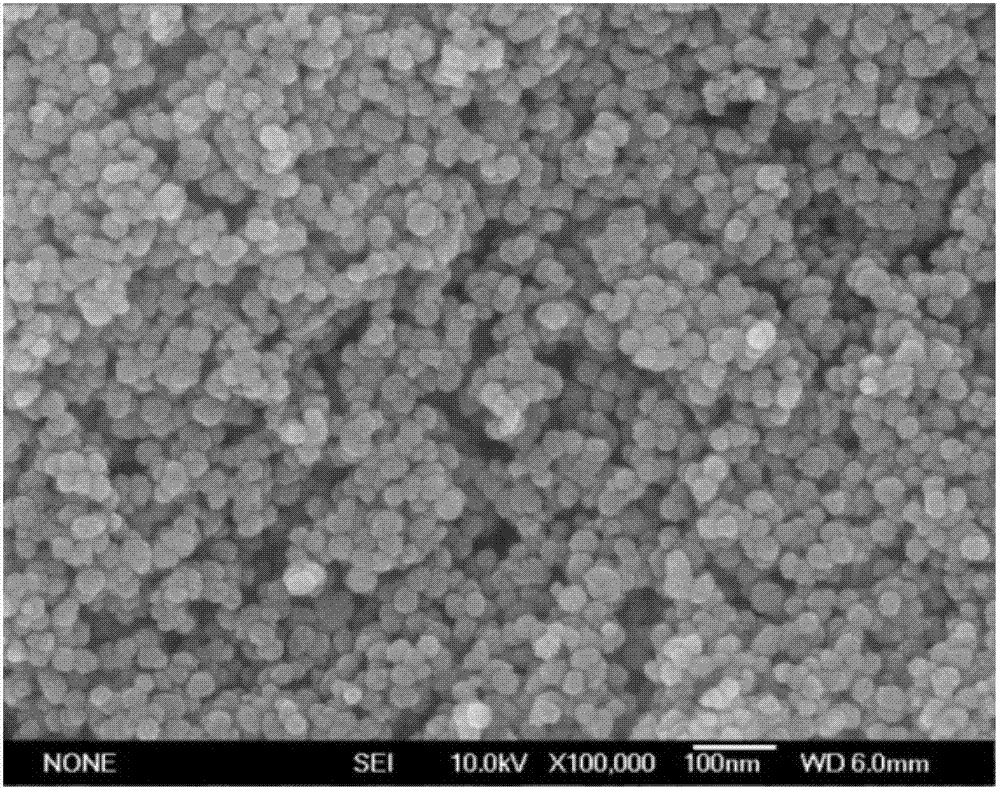

[0059] (1) Commercially purchased P25 titanium dioxide powder, lauric acid, and monoalkoxy pyrophosphate titanate coupling agent with a mass ratio of 2:0.1:0.01:1:6 (purchased from Changzhou Yabang Yayu Auxiliary Ltd), ethyl cellulose and terpineol blend.

[0060] (2) Put the mixture in a planetary ball mill, set the rotation speed at 600 revolutions per minute (rpm), and run for 12 hours to obtain a titanium dioxide slurry for screen printing.

[0061] (3) Preparation of titanium dioxide thin film photoanode.

[0062] Use indium tin oxide conductive glass as the conductive substrate, ultrasonically clean the surface of the conductive glass with a mixed solution of absolute ethanol and acetone with a volume ratio of 1:1 for 10 minutes, rinse it with deionized water three times after cleaning, and then place it in an oven at 100°C drying. The titanium dioxide paste was printed on the surface of the conductive glass by screen printing, the thickness of the titanium dioxide fil...

Embodiment 2

[0072] According to the method in Example 1, except that the following steps are modified, other steps are identical.

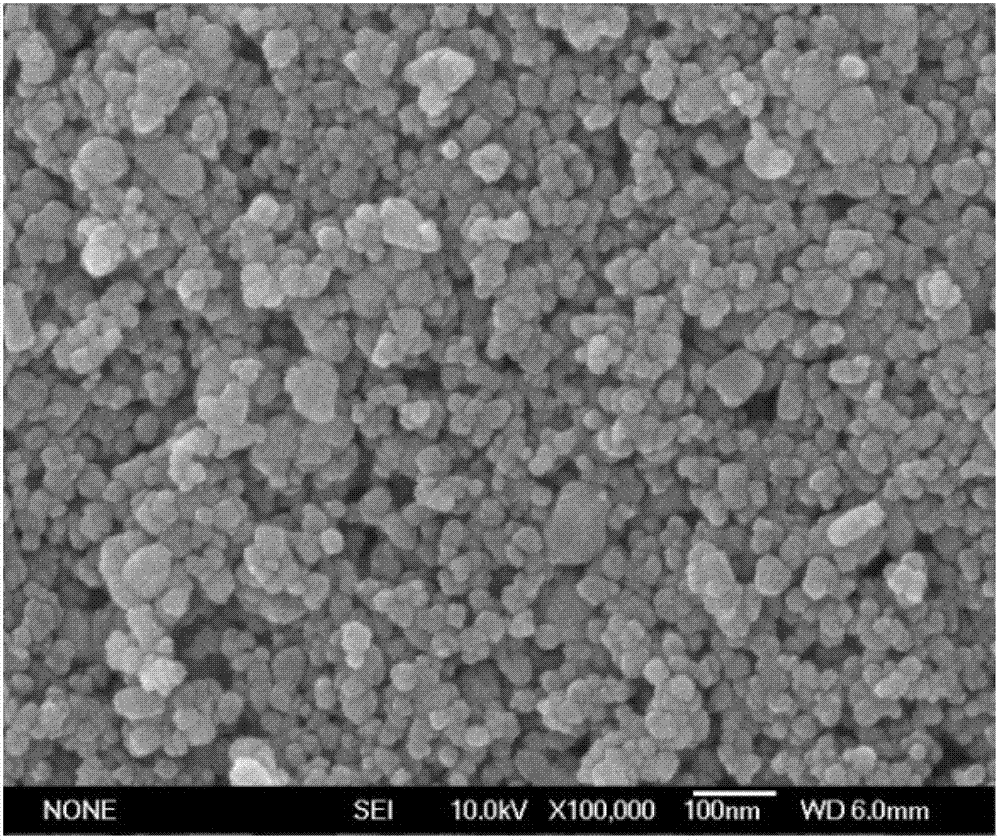

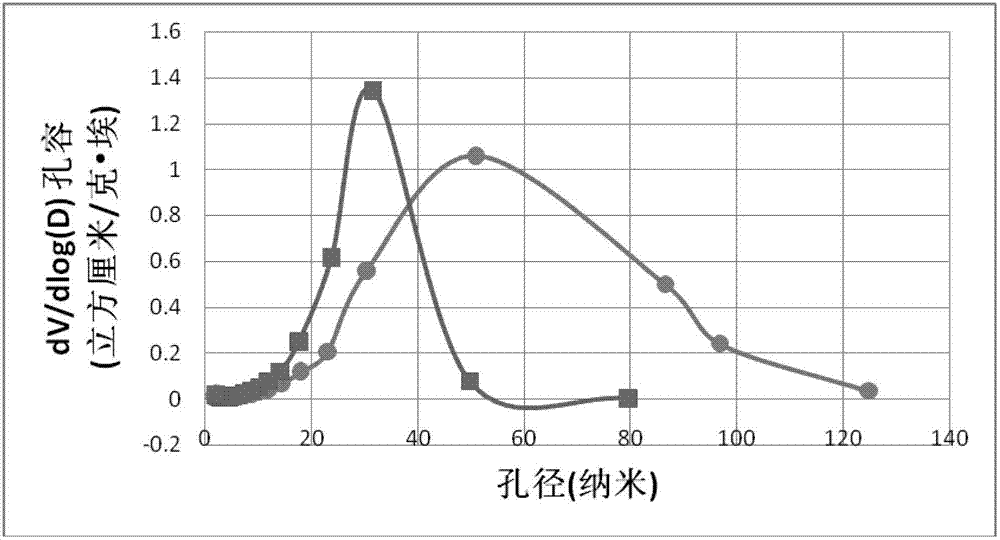

[0073] When preparing the titanium dioxide slurry, the commercially available titanium dioxide powder was Ishihara ST21 titanium dioxide powder (purchased from Ishihara Co., Ltd., Japan). During mechanical dispersion, the rotation speed of the planetary ball mill was set at 1000 rpm, and the running time was 6 hours.

[0074] When preparing the dye-sensitized single-layer titanium dioxide ternary nanocrystalline film photoanode, the concentration of the ethanol solution of N719 dye (purchased from Solaronix, Switzerland) was 0.4mmol / L.

[0075] Measure and calculate its short-circuit current (mA / cm2), open-circuit voltage (volt-ampere), fill factor (%) and cell conversion efficiency (%) according to the measurement method of the dye-sensitized solar cell of the present invention. The results are shown in Table 1 below.

[0076] Additionally, by figure 2 I...

Embodiment 3

[0078] According to the method in Example 1, except that the following steps are modified, other steps are identical.

[0079]When preparing the titanium dioxide slurry, the commercially available titanium dioxide powder was Degussa P25 (purchased from Degussa Company), and the surfactant was Triton-100 (a kind of polyethylene glycol octylphenyl ether, purchased from Sinopharm Group Chemical Reagent Co., Ltd.), the hyperdispersive coating agent is a chelating titanate coupling agent (purchased from Changzhou Yabang Yayu Auxiliary Co., Ltd.), titanium dioxide, surfactant, hyperdispersive coating agent, viscosity adjustment The mass ratio of agent and solvent is 2:0.1:0.05:0.4:8. During mechanical dispersion, the planetary ball mill was set at a rotating speed of 500rpm, and the running time was 10 hours.

[0080] When preparing the titanium dioxide thin film photoanode, the thickness of the titanium dioxide film is 22 microns.

[0081] When preparing the dye-sensitized single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com