Heat pipe and ground source heat pump system

A heat pipe heat exchanger, heat pipe technology, applied in heat pumps, geothermal power generation, indirect heat exchangers, etc., can solve the problems of insufficient cooling capacity and ventilation limit, affecting the working conditions of underground workers, and difficult to meet actual needs, etc. Simple and convenient maintenance, high energy conversion efficiency, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

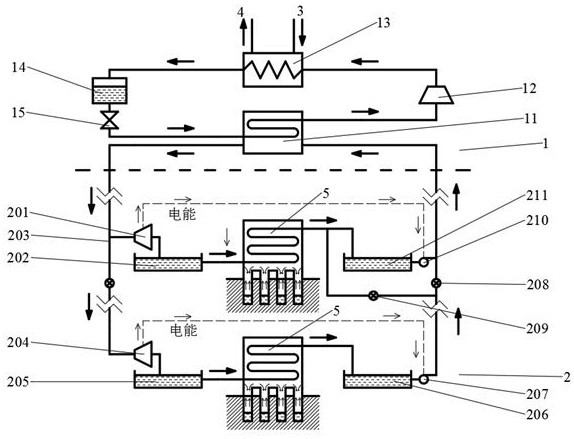

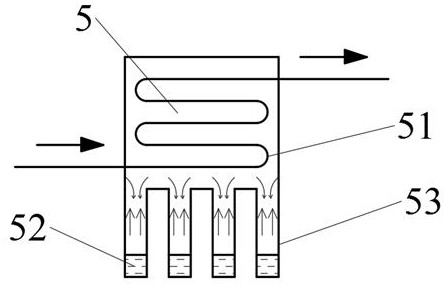

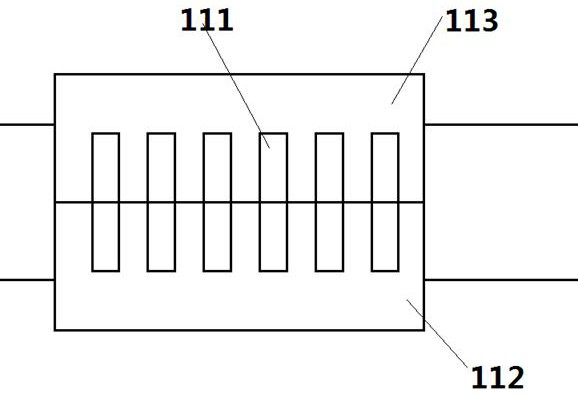

[0042] Such as Figure 1-9A mine ground source heat pump utilization system shown includes a ground heat pump unit 1 and an underground water network system 2. The underground water network system 2 includes an underground heat pipe heat exchanger 5 and a hot water dam (hot waterdam) 211 sequentially connected by pipelines , heat exchanger 11, turbine 201, cold water dam (cold water dam) 202, the water in the cold water dam 202 enters the underground heat pipe heat exchanger 5, and the water absorbs the thermal energy of the mine underground in the underground heat pipe heat exchanger 5, and then enters the heat The dam 211, then enters the heat exchanger 11 from the hot water dam 211 to release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com