Multi-anion doped single crystal high-nickel positive electrode material and preparation method thereof

A positive electrode material and polyanion technology, which is applied in the field of polyanion-doped single-crystal high-nickel positive electrode materials and its preparation, to achieve uniform distribution of doped anions, stable structure, and excellent doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

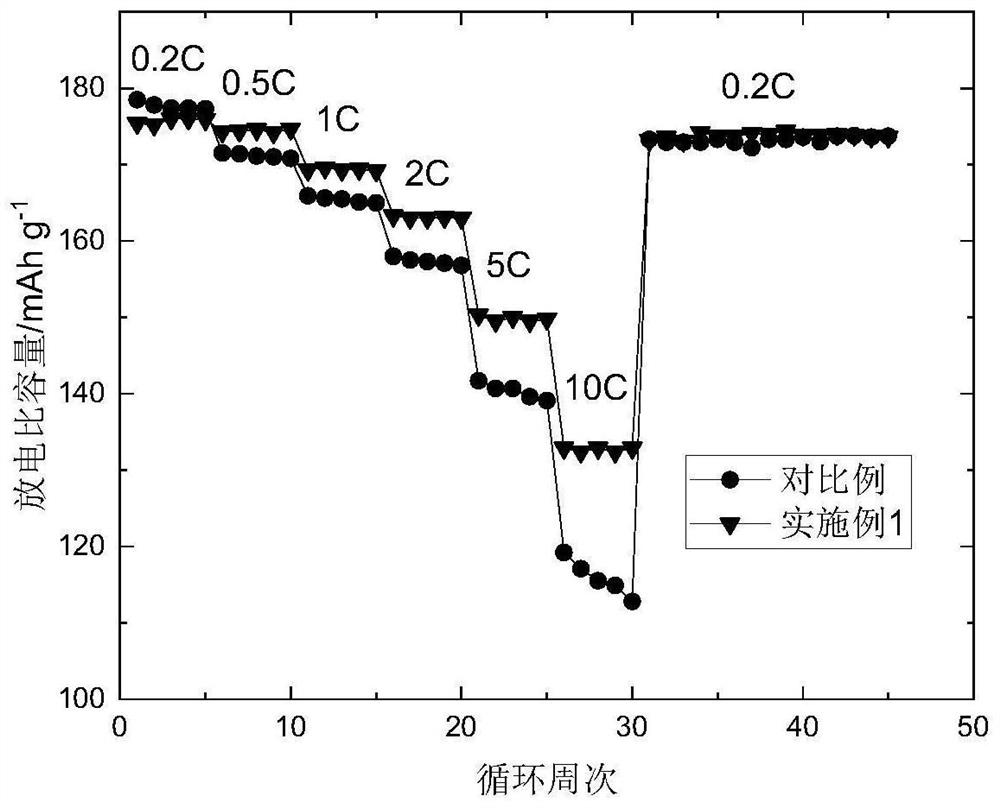

Embodiment 1

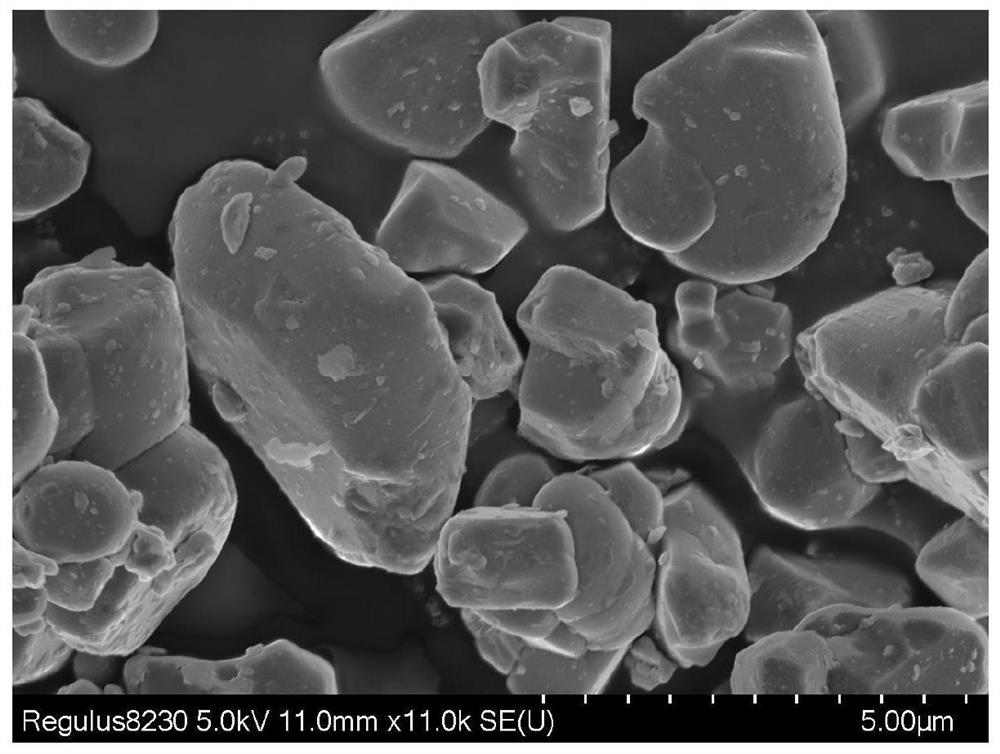

[0045] A method for doping a single-crystal high-nickel positive electrode material with polyanions, comprising the following steps:

[0046] S1. Weigh the prepared 10g single crystal Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, 4.998g LiOH·H 2 O and 0.15g LiCl, the three are uniformly mixed by absolute ethanol, and ground for 30min in a mortar, until the complete volatilization of absolute ethanol obtains the first mixture;

[0047] S2. The first mixture is placed in a tube furnace, and calcined under an oxygen atmosphere, and the temperature is raised to 580° C. at a controlled heating rate of 5° C. / min. The temperature is kept at 8 hours, and then the temperature is raised to 700° C. at a controlled heating rate of 2° C. / min. Insulated for 8 hours, and the calcined material was cooled to obtain Cl-doped - single crystal high nickel ternary material;

[0048] S3, weigh 0.15g elemental S and S2 mixed with Cl - 10g of single-crystal high-nickel ternary materials were placed i...

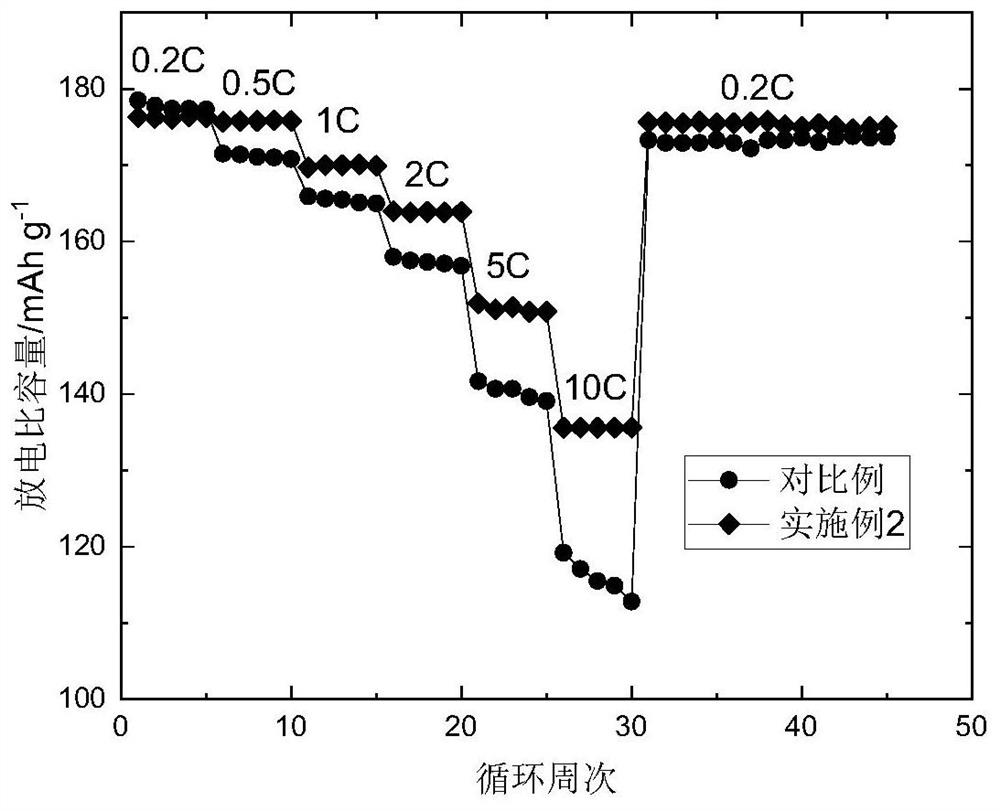

Embodiment 2

[0052] A method for doping a single-crystal high-nickel positive electrode material with polyanions, comprising the following steps:

[0053] S1. Weigh the prepared 10g single crystal Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, 4.998g LiOH·H 2 O and 0.2gNH 4 F, using absolute ethanol to uniformly mix the three, and grind for 30 minutes in a mortar, until the absolute ethanol is completely volatilized to obtain the first mixture;

[0054] S2. The first mixture is placed in a tube furnace and calcined under an oxygen atmosphere. The heating rate is controlled at 5°C / min and the temperature is raised to 580°C. The temperature is kept at 15h, and then the temperature is raised to 1000°C at a controlled heating rate of 2°C / min. Insulated for 15h, and the calcined material was cooled to obtain a mixture doped with F - single crystal high nickel ternary material;

[0055] S3, weighed 0.15g thioacetamide and S2 obtained doped with F -10g of the single-crystal high-nickel ternary ma...

Embodiment 3

[0058] A method for doping a single-crystal high-nickel positive electrode material with polyanions, comprising the following steps:

[0059] S1. Weigh the prepared 10g single crystal Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, 4.998g LiOH·H 2 O and 0.1gKCl, utilize dehydrated ethanol to uniformly mix the three, grind in a mortar for 30min, and treat that dehydrated ethanol is completely volatilized to obtain the first mixture;

[0060] S2. The first mixture is placed in a tube furnace and calcined under an oxygen atmosphere. The heating rate is controlled at 5°C / min and the temperature is raised to 580°C. The temperature is kept for 10 hours, and then the temperature is raised to 800°C at a controlled heating rate of 2°C / min. Insulated for 10h, the calcined material was cooled to obtain the Cl-doped - single crystal high nickel ternary material;

[0061] S3, weigh 0.15g LiF and S2 obtained doped with Cl - 10g of the single-crystal high-nickel ternary material were placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com