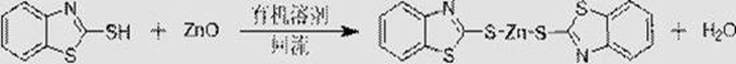

Novel process for synthesizing 2-thiol benzothiazole zinc salt by adopting solvent method

A technology of mercaptobenzene and benzothiazole, which is applied in the field of rubber accelerators, can solve the problems of increased waste water treatment costs and comprehensive production costs, and achieves the effects of short production cycles, reduced production costs, and no corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 88.13 g (0.5 mol) of 2-mercaptobenzothiazole, 20.7 g (0.26 mol) of zinc oxide, 500 ml of toluene solvent, and 0.5 g of glacial acetic acid as a catalyst into the four-necked reaction flask. Seal it with a rubber stopper, heat it to reflux under normal pressure, and complete the reaction after 3 hours. After filtering and drying, the product ZMBT is obtained as a pale yellow solid. The detected reaction yield was 97.6%, and the initial melting point was 220.8°C.

Embodiment 2

[0019] Add 100 g (0.57 mol) of 2-mercaptobenzothiazole, 23.4 g (0.29 mol) of zinc oxide, 500 ml of ethyl acetate solvent, and 0.5 g of catalyst glacial acetic acid into the four-necked reaction flask, add condensation and reflux to separate water The device is sealed with a rubber stopper, heated to reflux under normal pressure, and the reaction is completed after 3 hours, and the product is obtained as a pale yellow solid ZMBT through filtration and drying processes. The detected reaction yield was 98.1%, and the initial melting point was 222.7°C.

Embodiment 3

[0021] Add 88.13 g (0.5 mol) of 2-mercaptobenzothiazole, 20.7 g (0.26 mol) of zinc oxide, 500 ml of toluene solvent, and 0.5 g of catalyst propionic acid into the four-necked reaction flask, and add a condensation reflux water separation device, Seal it with a rubber stopper, heat it to reflux under normal pressure, and complete the reaction after 3 hours. After filtering and drying, the product ZMBT is obtained as a pale yellow solid. The detected reaction yield was 98.4%, and the initial melting point was 222.5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com