Colored damp-proof wall ground reinforcing agent and preparation method thereof

A wall surface and reinforcing agent technology, applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve problems such as poor coloring effect, limited dust and sand fixation, poor water resistance of coatings, etc., to achieve Improve brushing and application performance, good covering effect, good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

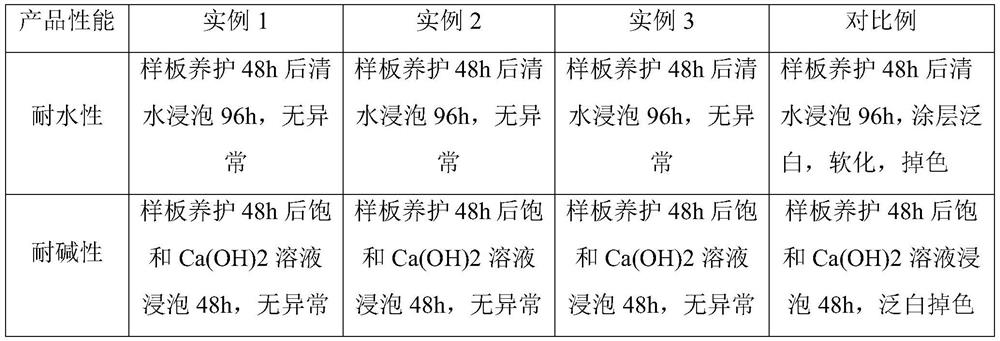

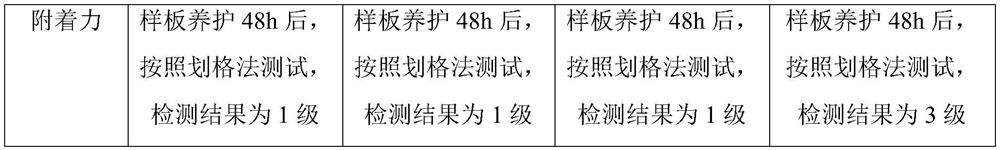

Examples

Embodiment 1

[0024] The invention provides a preparation method of a color moisture-proof wall ground reinforcement, which specifically includes the following steps:

[0025] (1) Weigh 460 parts by mass of water, 2 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 5 parts by mass 400 colloidal attapulgite, 2 parts by mass of Dow LX300, 2 parts by mass of Kemet 2290 defoamer, 2 parts by mass of ECOSURF TM BD-109 surfactant, 2 mass parts special good powder TM 1620 dispersant, 1 mass part of AMP-95pH regulator, 10 mass parts of propylene glycol, 150 mass parts of 400 mesh calcium carbonate, 200 mass parts of 1200 mesh calcium carbonate, 150 mass parts of Bailimo TM DC-420, 7.5 parts by mass of alcohol ester twelve, 4 parts by mass of Yale Shun TM DR-50 and 6 mass parts world famous water-based color paste.

[0026] (2) 460 parts by mass of water, 2 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 5 parts by mass 400 colloidal attapulgite is thrown into the container ...

Embodiment 2

[0031] The invention provides a preparation method of a color moisture-proof wall ground reinforcement, which specifically includes the following steps:

[0032] (1) Weigh 500 parts by mass of water, 4 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 2 parts by mass 400 colloidal attapulgite, 2 parts by mass of fungicide, 2 parts by mass of Kemet 2290 defoamer, 2 parts by mass of ECOSURF TM BD-109 surfactant, 3 parts by mass of special good powder TM 1620 dispersant, 1 mass part of AMP-95pH regulator, 8 mass parts of propylene glycol, 200 mass parts of 400 mesh calcium carbonate, 170 mass parts of 1200 mesh calcium carbonate, 100 mass parts of Bailimo TM DC-420, 5 parts of alcohol ester twelve, 3 parts of Ya Lesun TM DR-50 and 5 parts by mass of world-famous water-based color paste.

[0033] (2) 500 parts by mass of water, 4 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 2 parts by mass 400 colloidal attapulgite is thrown into the container and disp...

Embodiment 3

[0038] The invention provides a preparation method of a color moisture-proof wall ground reinforcement, which specifically includes the following steps:

[0039] (1) Weigh 400 parts by mass of water, 5 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 2 parts by mass 400 colloidal attapulgite, 5 parts by mass of fungicide, 5 parts by mass of Kemet 2290 defoamer, 5 parts by mass of ECOSURF TM BD-109 surfactant, 5 parts by mass of special good powder TM 1620 dispersant, 3 parts by mass of AMP-95pH regulator, 5 parts by mass of propylene glycol, 100 parts by mass of 400 mesh calcium carbonate, 100 parts by mass of 1200 mesh calcium carbonate, 200 parts by mass of Bailimo TM DC-420, 10 parts by mass of alcohol ester twelve, 5 parts by mass of Yale Shun TM DR-50 and 8 mass parts world famous water-based color paste.

[0040] (2) 400 parts by mass of water, 5 parts by mass of Cellulose TM 893 hydroxyethyl cellulose, 2 parts by mass 400 colloidal attapulgite is thrown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com