Self-cleaning road marking coating and preparation method thereof

A road marking and self-cleaning technology, applied in the direction of coating, etc., can solve the problems of prolonging the braking distance of cars, pedestrians slipping, increasing safety hazards, and low surface smoothness, so as to save time and energy consumption and avoid reunion , the effect of simplifying the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

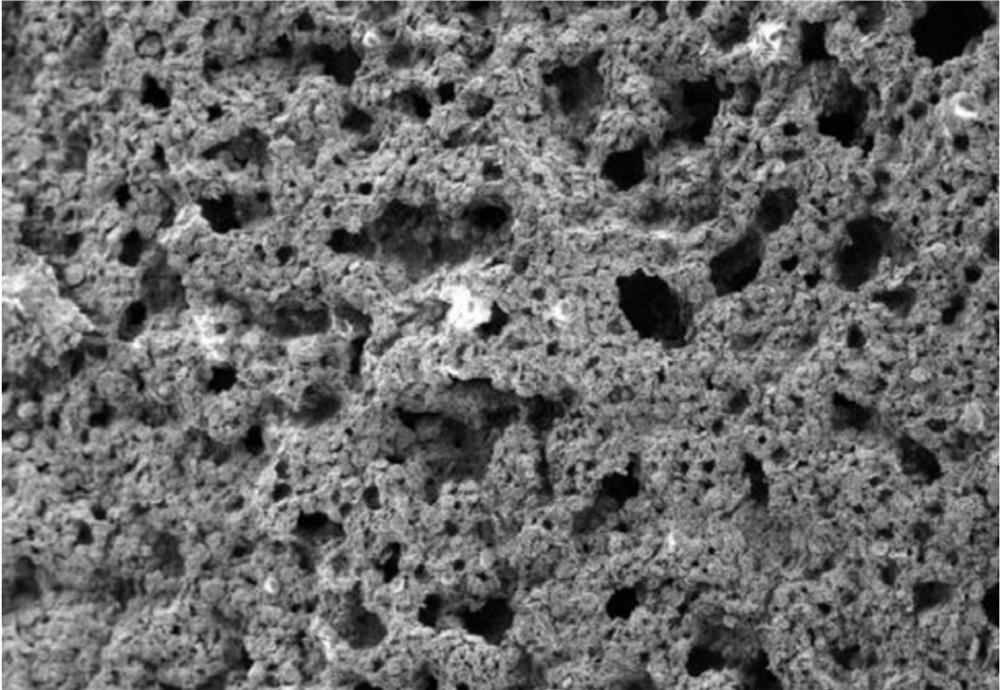

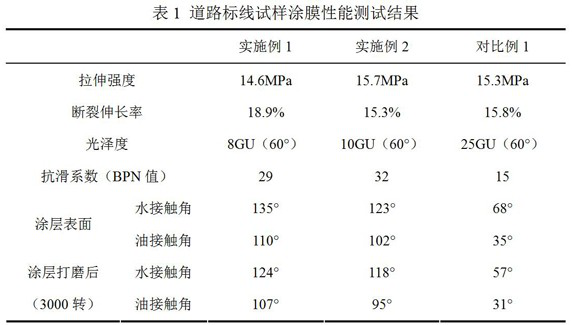

[0042] Weigh 60g methyl methacrylate, 30g butyl acrylate, 20g hydroxypropyl methacrylate, 80g Liaoning tricyclic TM A-02 solid acrylic resin, 180g porous silica microspheres, 20g nano-titanium dioxide (1000 mesh), sequentially added to the reaction vessel, stirred for 30min, then added 2g of perfluorodecyltrimethoxysilane coupling agent, continued stirring Heating to 80° C. under reflux for 1 hour to prepare a modified acrylic resin.

[0043] Take 100g of modified acrylic resin, add 0.2g of N,N-dimethylaniline, 10g of dimethyl silicone oil, 20g of 3M TM 7100 fluorinated liquid, stirred at 800r / min for 1 hour, and the discharged material was sealed and stored to obtain the A component of the self-cleaning road marking paint.

[0044] Take 100g of modified acrylic resin, add 3g of benzoyl peroxide, 10g of simethicone, 20g of 3M TM 7100 fluorinated liquid, stirred at 800r / min for 1 hour, and the discharged material was sealed and stored to obtain the B component of the self-cle...

Embodiment 2

[0050] Weigh 50g methyl methacrylate, 20g butyl acrylate, 10g hydroxypropyl methacrylate, 100g Liaoning tricyclic TM A-04 solid acrylic resin, 110g hollow glass microspheres, 10g nano-titanium dioxide (1000 mesh), sequentially added to the reaction vessel, stirred for 30min, then added 10g of dodecyltrimethoxysilane coupling agent, heated under continuous stirring Reflux at 60°C for 2 hours to prepare a modified acrylic resin.

[0051] Take 100g of modified acrylic resin, add 1g of N,N-dimethyl-p-toluidine, 8g of tung oil, and 30g of n-hexane, stir at 800r / min for 0.5 hours, and store the material in a sealed seal to obtain Group A of self-cleaning road marking paint point.

[0052] Take 100g of modified acrylic resin, add 5g of benzoyl peroxide, 8g of tung oil, and 30g of n-hexane, stir at 800r / min for 0.5 hours, and store the material in a sealed container to obtain component B of the self-cleaning road marking paint.

[0053] Mix component A and component B according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com