High-purity disilane continuous production system and preparation process

A production system, disilane technology, applied in the direction of silicon hydride, etc., can solve the problems of high purification costs, loss of target products, etc., and achieve the effect of shortening the residence time and avoiding the overheating of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

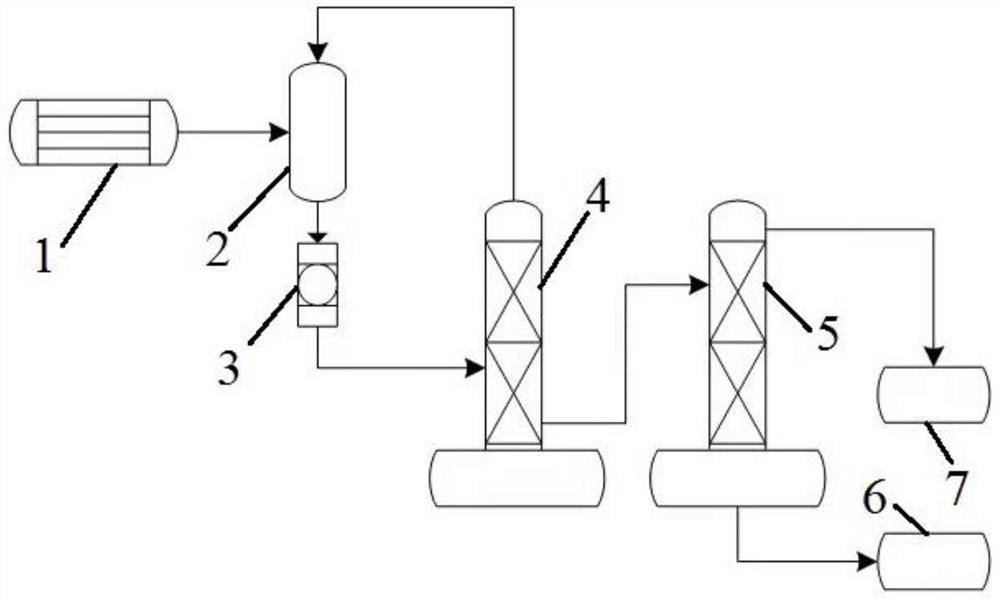

[0025] A high-purity disilane continuous production system, the feed pipeline is connected to one end of the preheater 1, the other end of the preheater 1 is connected to the feed end of the reactor 2 through the pipeline, and the discharge end of the reactor 2 is connected through the pipe The road is connected to one end of the filter 3, the other end of the filter 3 is connected to the rectification tower I4 through a pipeline, the top of the rectification tower I4 is connected to the feed end of the reactor 2 through a pipeline, and the bottom of the rectification tower I4 is passed through The pipeline is connected to the rectification tower II5, the top of the rectification tower II5 is connected to the collector 7 through the pipeline, and the bottom of the rectification tower II5 is connected to the mixing tank 6 through the pipeline.

[0026] The temperature of the preheater 1 is set at 380-400°C. The temperature of the reactor 2 is set at 430-480°C. The raw material...

Embodiment 2

[0028] A preparation process for continuous production of high-purity disilane, comprising the steps of:

[0029] 1) Start the preheater, preheat to 400°C, start the reactor, and preheat to 450°C; the preheater is a 316L stainless steel tube with a length of about 900mm and a diameter of 60mm; the volume of the reactor is 12L, and the length is 600mm;

[0030] 2) Feed the raw material silane into the preheater through the feed pipeline, the feed pressure of the raw material silane is 0.55MPa, and the feed rate is 3kg / hour;

[0031] 3) After the silane is preheated to 400°C in the preheater, it enters the reactor and undergoes a pyrolysis reaction at 450°C to produce disilane; the obtained material consists of 97.6wt% silane and 2.1wt% disilane;

[0032] 4) The product enters the filter for filtration to remove the silicon powder produced by decomposition;

[0033] 5) The intermediate feed enters the rectification tower I (diameter 100mm, θ ring packing, effective packing heig...

Embodiment 3

[0037] 1) Start the preheater, preheat to 380°C, start the reactor, and preheat to 430°C;

[0038] 2) Feed the raw material silane into the preheater through the feed pipeline, the feed pressure of the raw material silane is ≥0.2MPa, and the feed rate is 5kg / hour;

[0039] 3) Silane is preheated to 380°C in the preheater and then enters the reactor for pyrolysis reaction at 480°C to produce disilane;

[0040] 4) The reaction product enters the filter for filtration to remove the silicon powder produced by decomposition;

[0041] 5) Further enter the rectification tower I for purification, the silane obtained at the top of the rectification tower I at the top temperature enters the feed port of the reactor to continue the pyrolysis reaction, and the hydrogen gas obtained at the top of the rectification tower I at the top temperature is emptied , the bottom stream of rectification tower I includes disilane, trisilane, siloxane and other high-boiling substances into rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com