Method for preparing high-purity dicyclopentadiene by taking crude dicyclopentadiene as raw material

A technology for dicyclopentadiene and cyclopentadiene, which is applied in the field of preparing high-purity dicyclopentadiene, can solve the problems of small difference in copolymerization rate, influence yield, increase energy consumption, etc. The effect of the generation and the short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

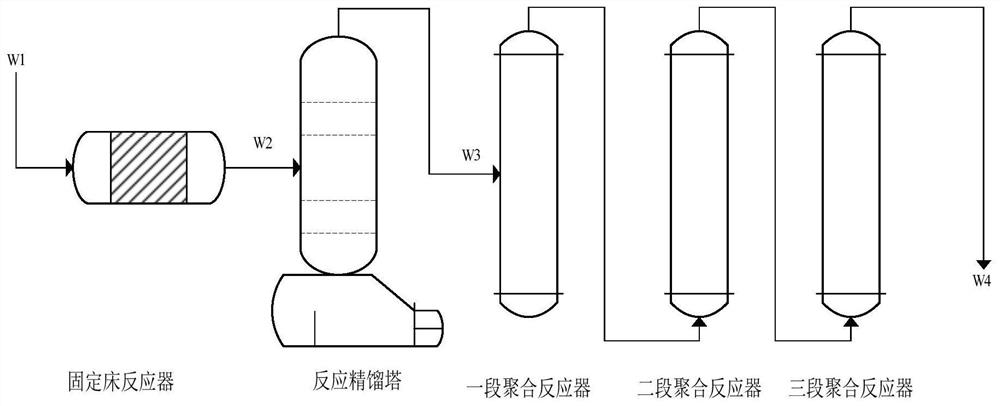

[0031] The technological process of embodiment 1~10 sees figure 1 , the raw material W1 first enters the fixed-bed reactor for hydrogenation reaction to obtain the hydrogenation product W2, and then enters the depolymerization rectification tower for separation. The theoretical plate number of the reaction rectification tower is 15, and high-purity CPD is obtained at the top of the tower Finished product W3, the tower kettle regularly discharges heavy component impurities. Then, the dimerization reaction is carried out through a three-stage polymerization reactor, and finally the DCPD finished product W4 is obtained.

[0032] The raw material W1 is a material rich in DCPD, and its main composition is shown in Table 1. In each embodiment, it passes through a fixed-bed reactor, a depolymerization rectification tower, a first-stage polymerization reactor, a second-stage polymerization reactor, and a three-stage polymerization reactor. The process operating conditions are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com