Preparation method of vincamine

A technology of vincamine and tabonin, which is applied in the preparation of compounds and the green production of vincamine, which can solve the problems of low production efficiency, long reaction time, and low degree of industrialization, and achieve safety issues and less manual operations , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

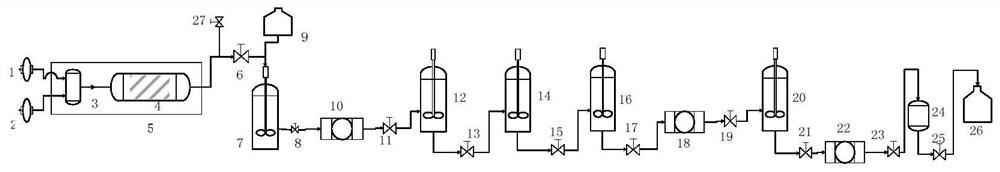

[0043] A preparation method of vincamine, comprising the following steps:

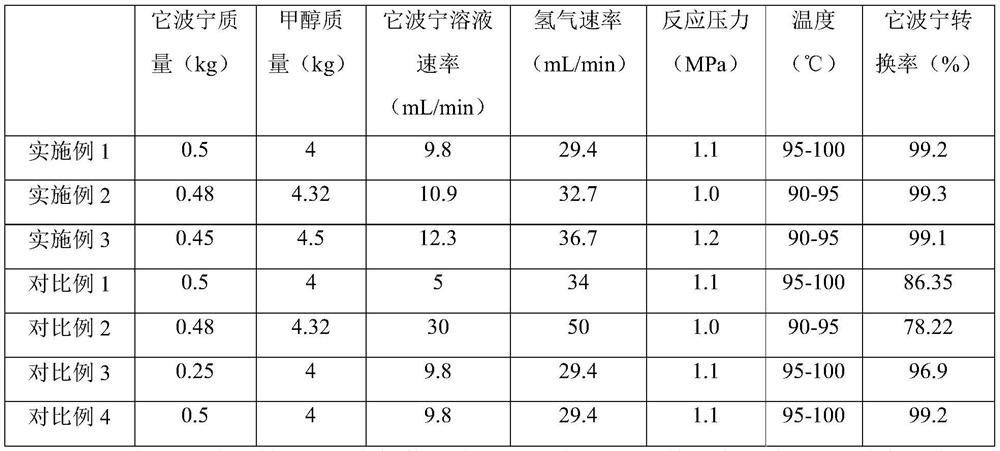

[0044] (1) Reduction: after nitrogen and hydrogen have replaced the microchannel reactor successively, the mixed solution of bonin and methyl alcohol and hydrogen are passed into the microchannel reactor 5 loaded with porous palladium catalyst by the feeding pump to carry out the reduction reaction, Set the reaction pressure to 0.8-1.2MPa, and the reaction temperature to 70-100°C; after the reaction is completed, the reaction liquid enters the neutralization tank 7, adjusts the pH to 6 with acetic acid, then filters through the filter 10, and the filtrate enters the stirring tank 12 to concentrate and mix Dichloromethane carries out extraction twice, obtains extract; Wherein step (1) specific experimental parameter value is as shown in table 1:

[0045] Table 1

[0046]

[0047] (2) Oxidation: the extract in the stirred tank 12 is passed into the reactor 14, then an oxidizing agent is added in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com