Hard polyimide foam material as well as preparation method and application thereof

A technology of polyimide and foam materials, applied in the field of polyimide foam materials, can solve the problems of unsatisfactory dielectric properties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] The present invention provides a method for preparing the rigid polyimide foam material as described in any one of the above technical solutions or the rigid polyimide foam material described in any one of the above technical solutions, comprising the following steps :

[0096] 1) After mixing the aromatic dianhydride and the solvent, adding low molecular weight alcohol to carry out the first reaction to obtain the first solution;

[0097] After mixing the dianhydride-type end-capping agent and the solvent, adding low-molecular alcohol to carry out the second reaction to obtain the second solution;

[0098] 2) After pre-mixing the first solution and the second solution obtained in the above steps, add fluorine-containing diamine to carry out the third reaction to obtain a polyimide precursor solution;

[0099] 3) After mixing the polyimide precursor solution, the foam stabilizer and the glass fiber obtained in the above steps again, and then removing the solvent, a pow...

Embodiment 1

[0137] (1) Add 20 parts of ODPA to 27 parts of THF, then add 6 parts of CH 3 OH reflux reaction, the temperature is 80°C, the time is 4.5h, and a transparent solution A is obtained;

[0138] (2) Add 8 parts of 5-norbornene-2,3-dicarboxylic anhydride to 10 parts of THF, then add 3 parts of CH 3 OH reflux reaction at a temperature of 60°C for 3 hours to obtain a transparent solution B;

[0139] (3) Cool solution A and solution B to room temperature, and stir and mix at a speed of 300 r / min for 30 minutes. Add 15 parts of 4-fluoro-1,2-phenylenediamine and react again to obtain a polyimide precursor solution at a temperature of 25°C for 3 hours;

[0140] (4) Add 6 parts of OFX-8417 and 1.5 parts of quartz glass fiber into the above precursor solution and stir and mix for 60 minutes at a speed of 500 r / min. Then carry out vacuum drying to remove the solvent, the temperature is 80°C, the time is 3h, and it is ground into a powdery product;

[0141] (5) Spread the powdery product...

Embodiment 2

[0147] (1) Add 22 parts of PMDA to 30 parts of DMF, then add 6 parts of C 2 h 5 OH reflux reaction at a temperature of 90°C for 3 hours to obtain a transparent solution A;

[0148] (2) Add 6 parts of 5-norbornene-2,3-dicarboxylic anhydride to 8 parts of DMF, then add 3 parts of C 2 h 5 OH reflux reaction at a temperature of 65°C for 4 hours to obtain a transparent solution B;

[0149] (3) Cool solution A and solution B to room temperature, and stir and mix at a speed of 350 r / min for 25 minutes. Add 18 parts of 4,4'-[1,4-phenylbis(oxygen)]bis[3-(trifluoromethyl)aniline and react again to obtain a polyimide precursor solution at a temperature of 25°C for 4 hours ;

[0150] (4) Add 8 parts of KF-96 and 3 parts of quartz glass fiber to the above precursor solution and stir and mix for 50 minutes at a speed of 600 r / min. Then carry out vacuum drying to remove the solvent, the temperature is 100°C, the time is 2h, and it is ground into a powder product;

[0151] (5) Spread t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

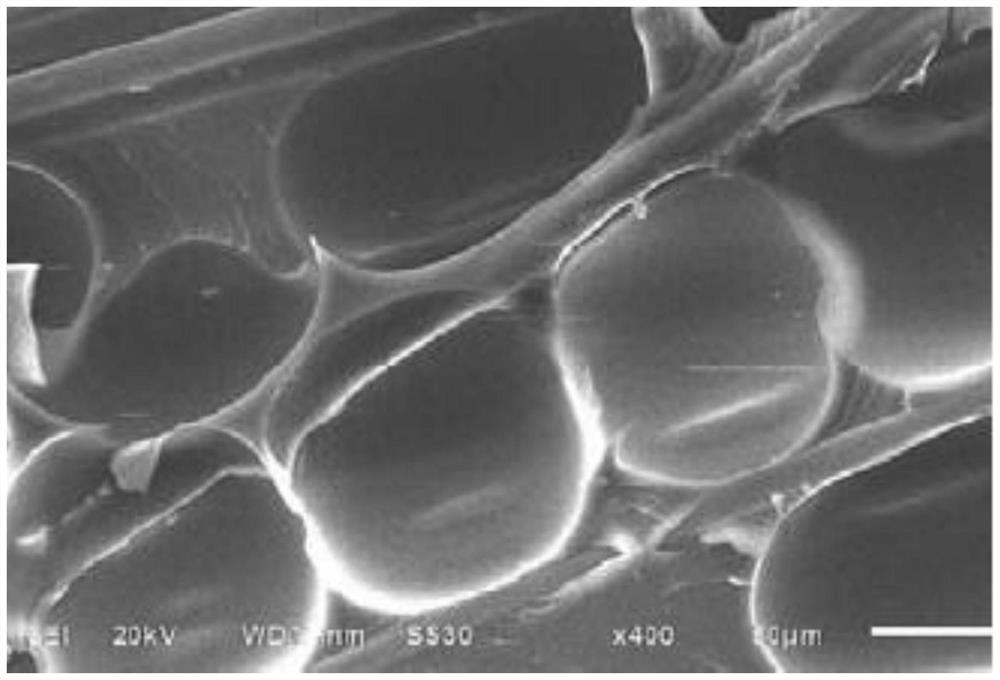

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com