Coal-bed gas well flushing fluid and preparation method and application thereof

A coalbed methane well and flushing fluid technology, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc., can solve the problems of environmental protection pressure, difficulty in degradation, high impurity content, etc., and achieve improved viscosity and shear Strength, improved rheology, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

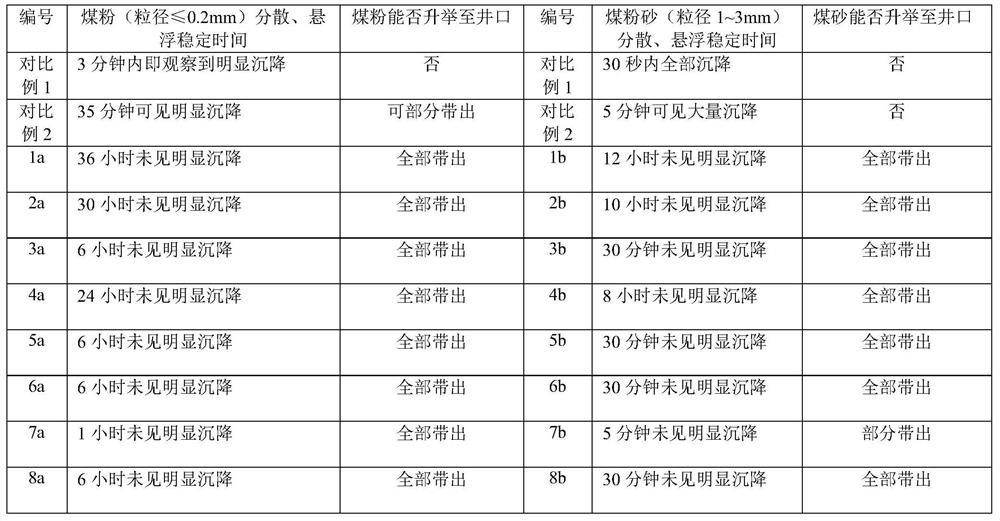

Embodiment 1

[0047] Weigh the required raw materials according to the mass ratio of 0.5% sodium alginate, 0.35% gelatin, 0.5% hydroxypropyl starch, 0.3% konjac gum, 0.25% xanthan gum, 0.1% scleroglucan, and 98% tap water, at room temperature Add sodium alginate, gelatin, hydroxypropyl starch, konjac gum, xanthan gum, and scleroglucan into water under certain conditions, and stir until all the added materials are dissolved. The solution obtained is the well-flushing fluid of the present invention.

Embodiment 2

[0049] According to 0.5% sodium alginate, 0.35% gelatin, 0.5% hydroxypropyl starch, 0.3% konjac gum, 0.25% xanthan gum, 0.1% scleroglucan, 98% of the original well produced water of the coalbed methane well in the Baode exploration area Weigh the required raw materials, mix sodium alginate, gelatin, konjac gum, xanthan gum, hydroxypropyl starch, and scleroglucan at room temperature, add them to the original well produced water of the coalbed methane well in the Baode exploration area, and stir The solution obtained until all the added materials are dissolved is the well washing fluid of the present invention.

Embodiment 3

[0051] According to 0.02% sodium alginate, 0.04% gelatin, 0.02% hydroxypropyl starch, 0.01% konjac gum, 0.2% xanthan gum, 0.01% scleroglucan, and 99.7% of the original well produced water of the coalbed methane well in the Baode exploration area Mass ratio Weigh the required raw materials, mix sodium alginate, konjac gum, hydroxypropyl starch, xanthan gum, gelatin, and scleroglucan at room temperature, add them to water, and stir until all the added materials are dissolved. That is the well washing fluid of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com