Antibacterial anti-allergy functional fabric and preparation method thereof

A functional and anti-allergic technology, applied in the field of fabrics, can solve the problems of easy allergy, decreased anti-allergic ability, disappearance, etc., and achieves the effect of large specific surface area and mild antibacterial allergy effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of porous fibers:

[0026] Take 1 part of polylactic acid and dissolve it in a mixed solution of dichloromethane and dimethylformamide at a volume ratio of 1:1, wherein the solid-liquid ratio of polylactic acid to the mixed solution is 1:10 (g / mL) to obtain polylactic acid Lactic acid solution; Polyvinyl alcohol is dissolved in dimethyl sulfoxide to obtain a polyvinyl alcohol solution, wherein the solid-liquid ratio is 1:15 (g / mL); the two obtained in step (1) and step (2) The two solutions are mixed at a volume ratio of 2:1 to obtain a spinning solution; the obtained spinning solution is obtained by electrospinning technology to obtain polylactic acid fibers, the polylactic acid fibers are ultrasonically treated in deionized water, and porous fibers are obtained after drying.

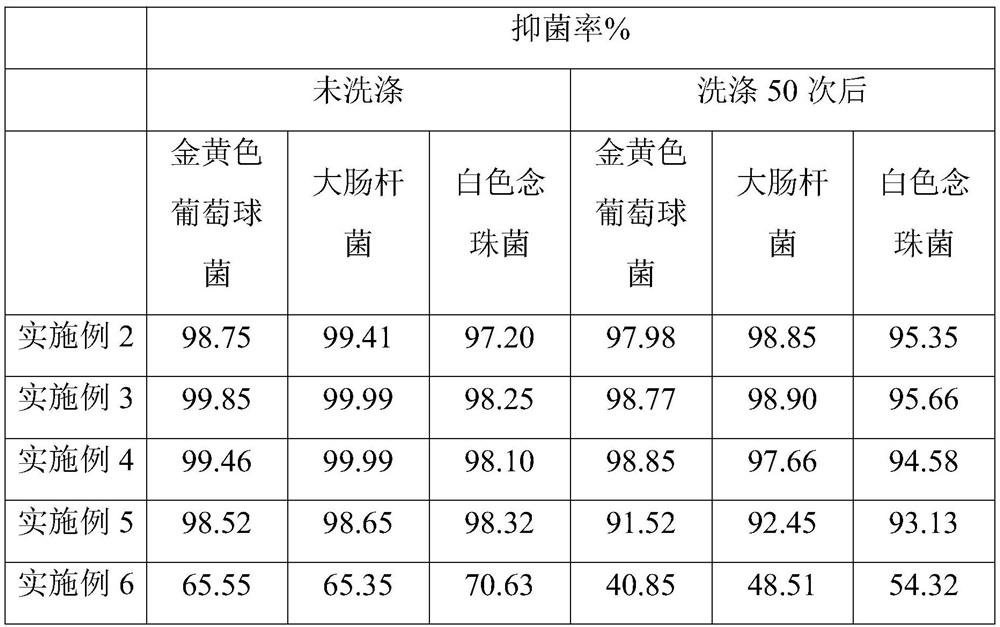

Embodiment 2

[0028] Weigh 1 portion each of honeysuckle, chamomile, ginkgo, parsnip, peppermint, astragalus, and angelica dahurica dry powder, and add them to the ethanol solution with a volume fraction of 80% according to the ratio of solid to liquid 1:30 (g / mL). Ultrasonic extraction was carried out 2 times, each ultrasonic extraction time was 30min, the filtrates were combined twice after suction filtration, and concentrated with a rotary evaporator to prepare extracts of each component, 5 parts of honeysuckle extract, 8 parts of chamomile extract , 3 parts of Ginkgo biloba extract, 3 parts of glycerin, 3 parts of Fangfeng extract, 2 parts of peppermint extract, 5 parts of Astragalus extract, 5 parts of Angelica root extract, 1 part of cross-linking agent, 1 part of emulsifier and 5 parts of tea tree oil Mix, stir evenly, add 150 parts of deionized water, stir to obtain the antibacterial antiallergic agent; the porous fibers and skeleton fibers obtained in Example 1 are padded in the ant...

Embodiment 3

[0030] Utilize the same method as Example 1 to prepare the extract, with 10 parts of honeysuckle extract, 12 parts of chamomile extract, 5 parts of ginkgo extract, 5 parts of glycerin, 6 parts of windproof extract, 5 parts of peppermint extract, and astragalus extract 8 parts, 8 parts of Angelica dahurica extract, 3 parts of crosslinking agent, 2 parts of emulsifying agent and 10 parts of tea tree oil mix, stir well, add 100 parts of deionized water, stir well to obtain antibacterial antiallergic agent; The porous fibers and the skeleton fibers are padded in an antibacterial and hypoallergenic agent, wherein the weight ratio of the porous fibers to the skeleton fibers is 1:1, and the skeleton fibers are selected from spandex fibers in this implementation, and the rolling rate is 75%, and then dried to obtain Mixed fibers; the mixed fibers are subjected to secondary padding and secondary drying; the mixed fibers after the secondary padding are washed, bleached, oiled, dried, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com