Coal blending combustion system and method

A combustion system and coal blending technology, which is applied in the field of coal blending and blending combustion systems, can solve the problems of insufficient safety protection in the coal-making process and insufficient combustion of mixed pulverized coal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

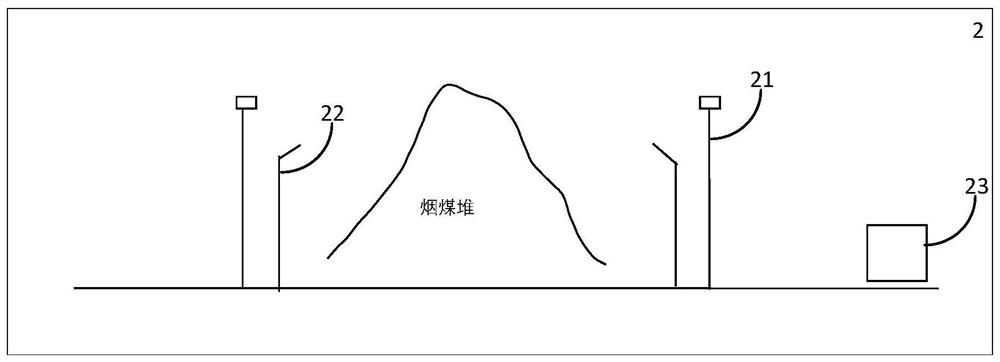

[0103] 6 temperature detectors 21 and 6 showers 22 are arranged in the stacking system, and the 6 temperature detectors 21 and 6 showers 22 are all circumferentially arranged around the coal pile. Wherein the temperature detector 21 and the shower 22 are all within the normal range to ensure that the temperature in each zone of the coal pile. The coal quality detector is installed in the coal bunker so that workers can check the quality of coal in the coal pile at any time.

Embodiment 2

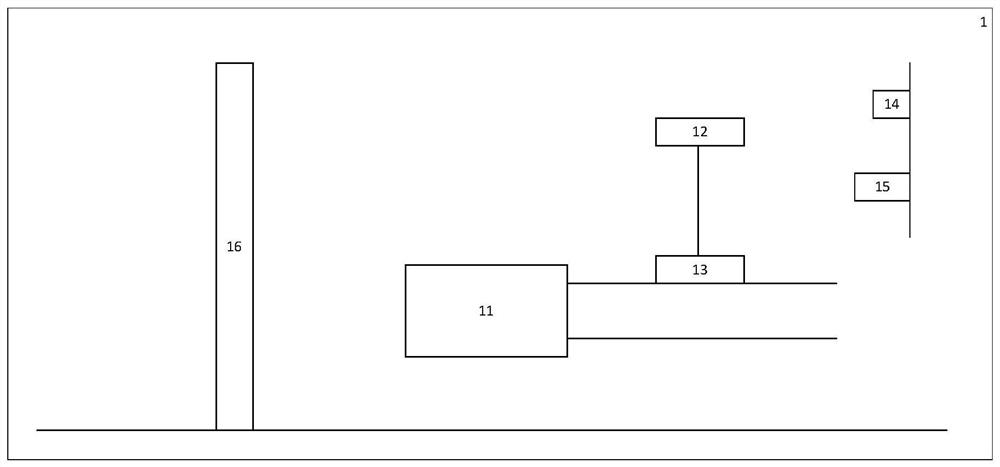

[0105] The gas outlet of the coal mill 11 is provided with a sensor 13, and the sensor transmits the outlet temperature, outlet coal fineness and primary wind speed to the server 12 through the wired network and / or wireless network. The combustible gas detection equipment 14 is arranged on the ceiling of the room where the coal mill 11 is located, and multiple shielding gas systems 15 can be installed and evenly distributed in the room to ensure that the room is filled with shielding gas at the fastest speed. The protective gas can be nitrogen and other inert gases. Explosion-proof doors 16 are arranged around the coal mill 11, generally with 1-3 floors, so as to reduce the explosion range as much as possible.

Embodiment 3

[0107] Lean coal powder and bituminous coal powder are blown into the swirl burner from two feed channels at a wind speed of 50 m / s according to a mass ratio of 1:1. The two air streams entering the swirl burner are blown in parallel through the stirring paddle in the mixing chamber, so that the stirring paddle rotates to mix the lean coal powder and bituminous coal powder in the air stream. Simultaneously, two air streams are designed to leave the mixing chamber from one air outlet to further mix the two pulverized coals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com