Quality control method for high-frequency longitudinal welded pipe

A technology of straight seam welded pipe and high frequency welded pipe, which is applied in the field of quality control of high frequency straight seam welded pipe, which can solve the problems of reducing the quality of welded seam, large residual stress of welded pipe, and large temperature difference in temperature distribution, so as to reduce the cost of adjustment process, Effect of quality improvement and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

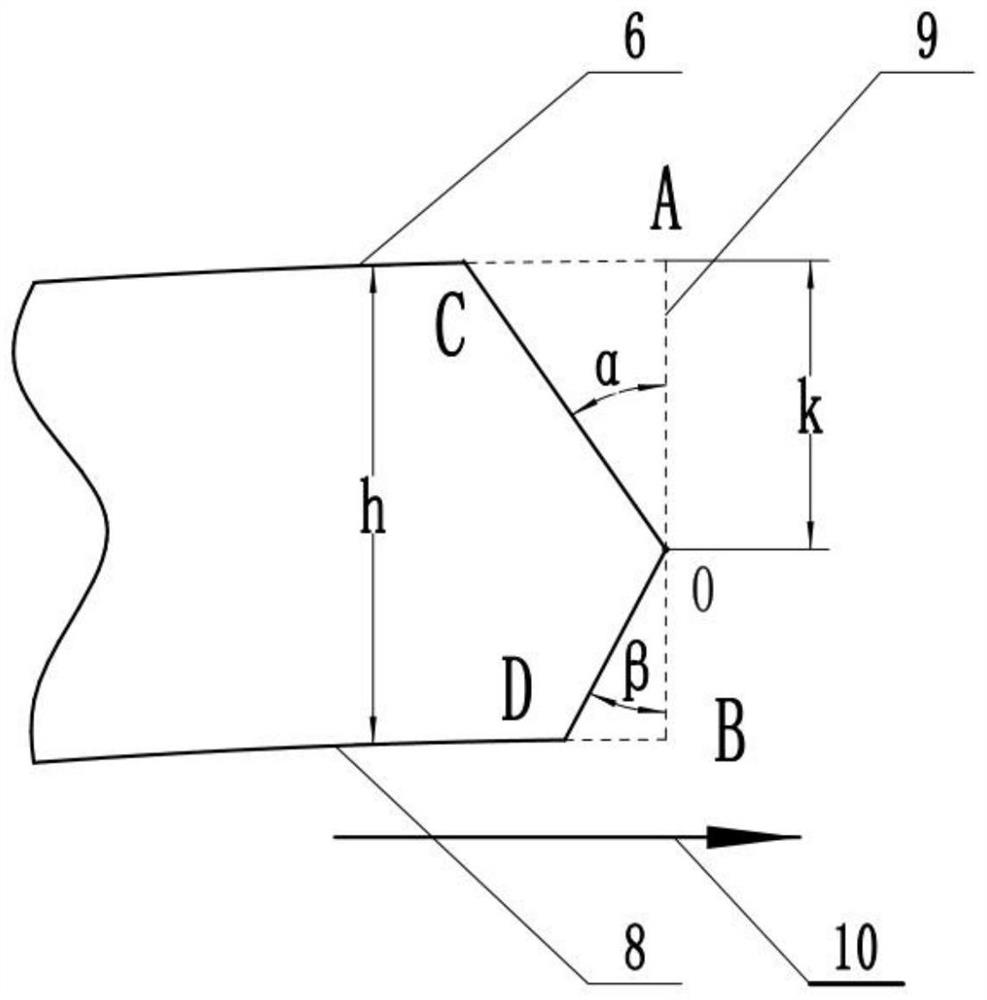

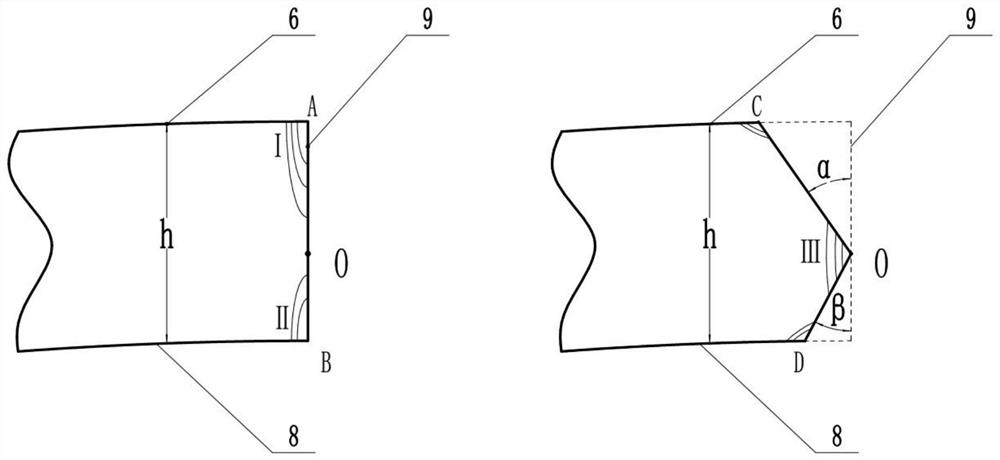

[0040] In order to better understand the technical solutions of the present invention, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. Now, by simulating the welding process of ERW pipe, observing the trimming control process of the pipe blank before welding, and observing its temperature distribution, to verify the feasibility of this method. The material of the ERW pipe is selected as X80 steel, and the specification is Φ355.6×12.7, and the numerical simulation is carried out.

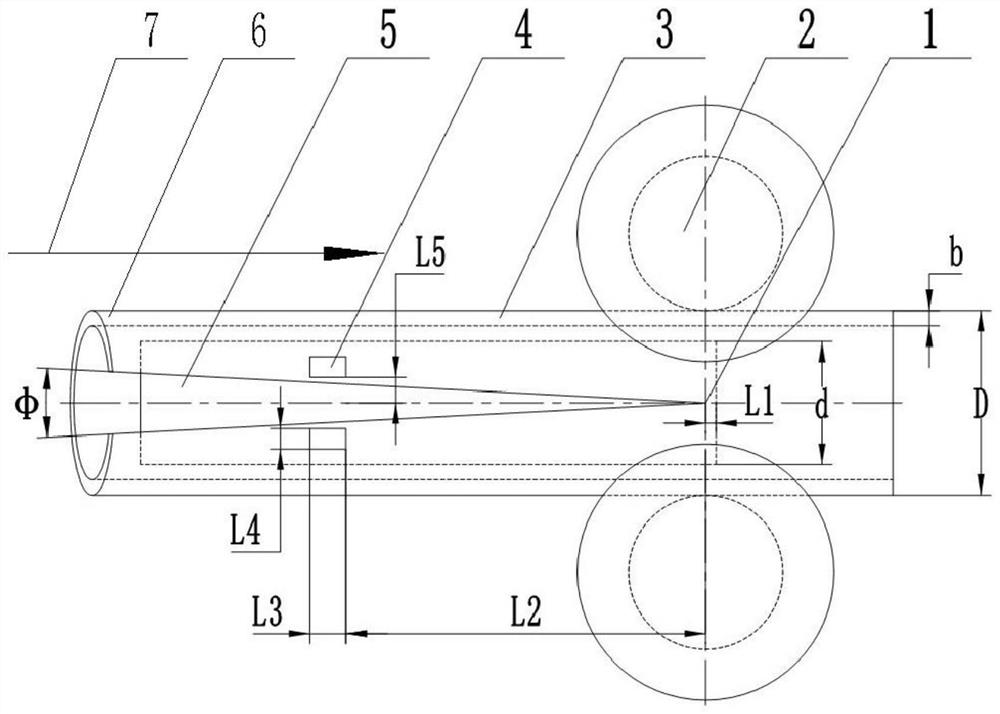

[0041] figure 1 It is a schematic diagram of the welding process of the present invention, wherein the electrode 4 is connected to an AC power source, and under the action of the electrode 4 and the magnetic bar 5, due to principles such as the skin effect, the temperature near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com