Silicone sealant, preparation method thereof and photovoltaic module

A silicone sealant, photovoltaic module technology, used in photovoltaic power generation, adhesives, electrical components and other directions, can solve problems such as difficult extrusion and curing, and achieve the effects of improved dispersibility, large market application value, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides the preparation method of described silicone sealant, comprises the following steps:

[0051] S10, mix the α,ω-dihydroxy polydimethylsiloxane, calcium carbonate filler and polycarboxylate water reducer, react at 60°C-80°C for 90min-120min, and heat up to 120°C-130°C °C, react in a vacuum environment for 120min to 180min, cool to normal temperature to obtain the base material; and

[0052] S20, adding the crosslinking agent, the coupling agent and the catalyst to the base material in sequence under a vacuum environment.

[0053] Preferably, step S20 further includes the following steps:

[0054] S21, under a vacuum environment, add a crosslinking agent to the base material for stirring, the rotation speed is 15HZ-20HZ, and the stirring time is 10min-20min;

[0055] S22, adding the coupling agent and the catalyst to the base material after adding the cross-linking agent for stirring, the rotation speed is 15HZ-20HZ, and the stirring t...

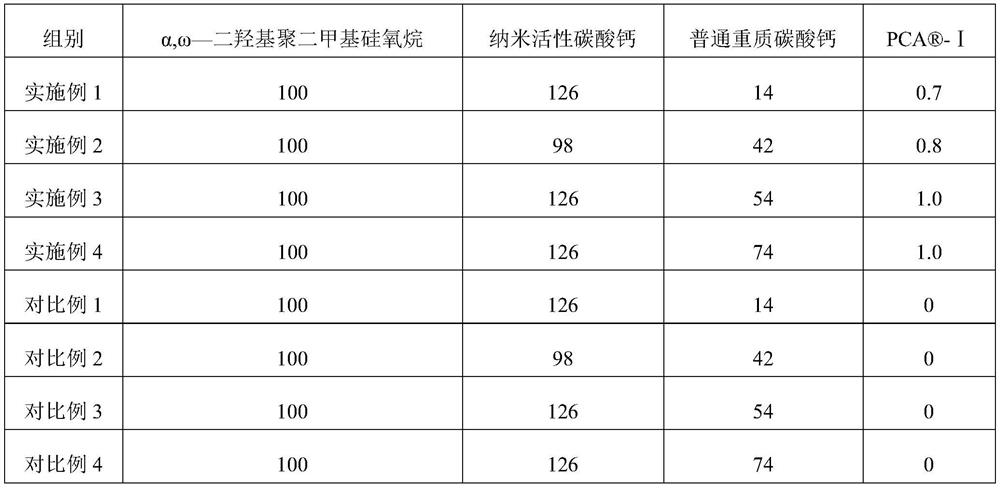

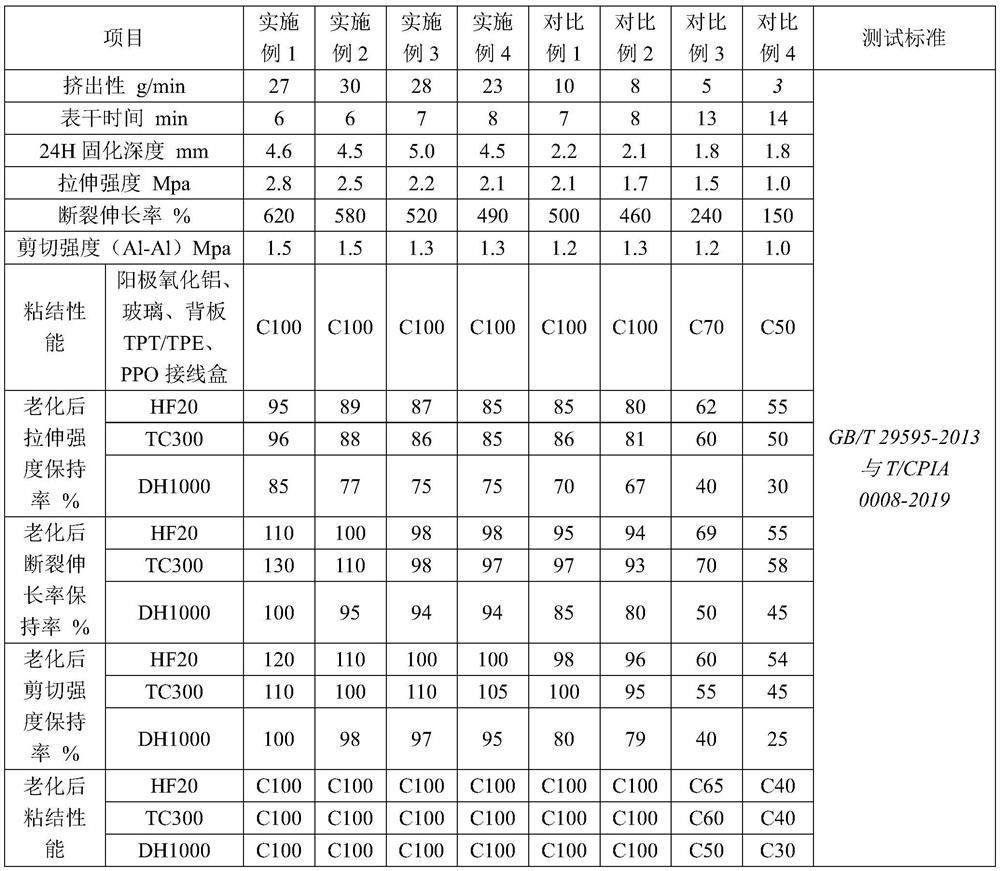

Embodiment 1

[0060] (1) 100 parts by weight of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 50000mpa.s at 25°C, 126 parts by weight of nano-active calcium carbonate, and 14 parts by weight of common heavy calcium carbonate, -I 0.7 parts by weight, put into a vacuum kneader, keep the temperature at 70°C, stir at a high speed for 100 minutes, then raise the temperature to 130°C, turn on the vacuum at the same time, the vacuum degree is -0.095MPa, stir at a high speed for 120 minutes, cool to room temperature to obtain the base material .

[0061] (2) Put the above-mentioned base material, 4 parts by weight of tetrabutylketoxime silane, 3 parts by weight of methyl tributylketoxime silane, and 3 parts by weight of vinyl tributylketoxime silane into a planetary mixer, and water-cooled control At room temperature, keep a vacuum of -0.095MPa, rotate at 17HZ, stir for 10 minutes, then continue to add the composition of γ-(2,3 glycidoxy)propyltrimethoxysilane and γ-aminopropyltrimethoxy...

Embodiment 2

[0063] (1) 100 parts by weight of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 50000mpa.s at 25°C, 98 parts by weight of nano-active calcium carbonate, and 42 parts by weight of ordinary heavy calcium carbonate, -I 0.8 parts by weight, put into a vacuum kneader, keep the temperature at 70°C, stir at a high speed for 100 minutes, then raise the temperature to 130°C, turn on the vacuum at the same time, the vacuum degree is -0.095MPa, stir at a high speed for 120 minutes, cool to room temperature to obtain the base material .

[0064] (2) Put the above-mentioned base material, 4 parts by weight of tetrabutylketoxime silane, 3 parts by weight of methyl tributylketoxime silane, and 3 parts by weight of vinyl tributylketoxime silane into a planetary mixer, and water-cooled control At room temperature, keep a vacuum of -0.095MPa, rotate at 17HZ, stir for 10 minutes, then continue to add the composition of γ-(2,3 glycidoxy)propyltrimethoxysilane and γ-aminopropyltrimethoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com