A kind of production process of extracting neutral oil from soapstock

A production process, neutral oil technology, applied in the recovery of fat oil/fatty acid from waste, production of fat, recovery of fatty substances, etc. problems such as poor oil extraction, to achieve efficient utilization of clean production, improve oil refining yield, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

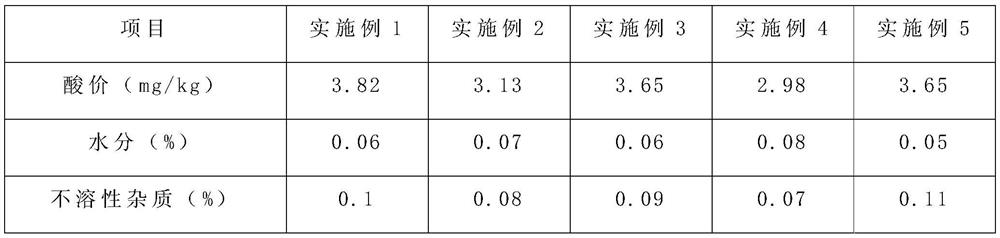

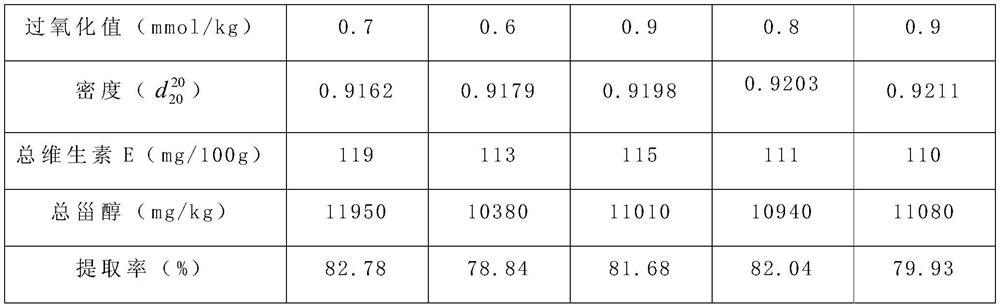

Examples

Embodiment 1

[0023] Embodiment 1 corn germ soapstock carries out neutral oil extraction 1

[0024] A production process for extracting neutral oil from soapstock, the process is as follows:

[0025] (1) Dilute the soapstock, the weight-to-volume (g / ml) ratio of soapstock to water is 100:75; control the stirring speed to 70 rpm, add water to dilute the soapstock, and form a diluted, neutral oil Evenly distributed soap stock;

[0026] (2) primary demulsification: add sodium chloride in the soapstock liquid, the particle diameter of sodium chloride is between 30-50 μ m, the weight (g / g) ratio of sodium chloride and soapstock is 8:100, then Stir under the condition of 60 rpm / min, while heating the soapstock liquid, heat it up to 65°C at a heating rate of 8°C / min, keep it warm for 5min, and obtain the broken emulsion I;

[0027] (3) Secondary demulsification: Control the temperature of demulsification I to 70°C, then add filter aid, the mass (g / g) ratio of filter aid to soapstock is 0.6:1000,...

Embodiment 2

[0029] Embodiment 2 corn germ soapstock carries out neutral oil extraction 2

[0030] A production process for extracting neutral oil from soapstock, the process is as follows:

[0031] (1) Dilute the soapstock, the weight-to-volume (g / ml) ratio of soapstock to water is 100:70; control the stirring speed to 50 rpm, and dilute the soapstock with water to form a diluted, neutral oil Evenly distributed soap stock;

[0032] (2) One-time demulsification: Add sodium sulfate to the soapstock liquid, the particle size of sodium sulfate is between 30-50 μm, the weight (g / g) ratio of sodium sulfate and soapstock is 5:100, and then turn at 30 Stir under the condition of 1 / min, heat the soapstock liquid at the same time, heat up to 50°C at a heating rate of 8°C / min, keep it warm for 7min, and obtain the broken emulsion Ⅰ;

[0033] (3) Secondary demulsification: Control the temperature of demulsification I to 50°C, then add filter aid, the mass (g / g) ratio of filter aid to soapstock is 0...

Embodiment 3

[0035] Embodiment 3 corn germ soapstock carries out neutral oil extraction 3

[0036] A production process for extracting neutral oil from soapstock, the difference from Example 1 is that in the primary demulsification process of step (2), the weight (g / g) ratio of salt to soapstock is 6:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com