A kind of Bacillus coagulans and its method for preparing L-lactic acid

A technology of Bacillus coagulans and lactic acid, which is applied in the field of biological fermentation engineering, can solve the problems of decreased yield, decreased physical and chemical indicators of products, increased energy consumption, etc., and achieves the effect of simple and economical fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This example provides a Bacillus coagulans FYLR2, which is preserved in the China Center for Type Culture Collection with the preservation number CCTCC M2020371, and its 16s rRNA sequence is shown in the sequence table as SEQ ID No: 1.

Embodiment 2

[0086] This example provides a batch fermentation method for preparing L-lactic acid in a 50L fermenter using the Bacillus coagulans provided in Example 1.

[0087] The medium composition used in this embodiment is as follows:

[0088] Incline medium: glucose 10g / L, yeast powder 10g / L, peptone 5g / L, calcium carbonate 20g / L, agar powder 20g / L, pH 6.0;

[0089] Seed medium: glucose 80g / L, yeast powder 10g / L, peptone 5g / L, calcium carbonate 40g / L, pH 6.0;

[0090] Fermentation medium: glucose 220g / L, yeast powder 0.5g / L, potassium dihydrogen phosphate 2.3g / L, dipotassium hydrogen phosphate 1.15g / L, ammonium sulfate 15g / L, sodium chloride 1g / L, dihydrogen phosphate Ammonium 0.5g / L, ferric chloride 0.3g / L, biotin 50ppm, vitamin B1 50ppm, and the balance is water; the pH of the fermentation medium is 6.0, and it is sterilized at 115°C for 20 minutes;

[0091] The preparation method is as follows:

[0092] (1) Slant culture: Bacillus coagulans FYLR2 was inoculated on the slant med...

Embodiment 3

[0097] This example provides a batch fermentation method for preparing L-lactic acid in a 50L fermenter using the Bacillus coagulans provided in Example 1.

[0098] The difference from Example 2 is that the fermentation medium of this example is: corn saccharification liquid total sugar 220g / L, yeast powder 0.5g / L, potassium dihydrogen phosphate 2.3g / L, dipotassium hydrogen phosphate 1.15g / L , ammonium sulfate 15g / L, sodium chloride 1g / L, diammonium phosphate 0.5g / L, ferric chloride 0.3g / L, biotin 50ppm, vitamin B1 50ppm, and the balance is water; The pH is 6.2, and it is sterilized at 115°C for 20 minutes.

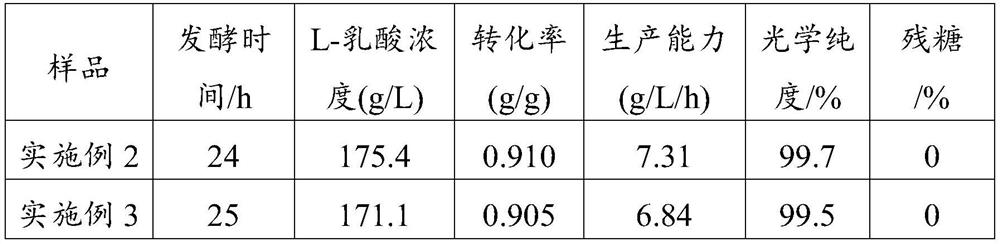

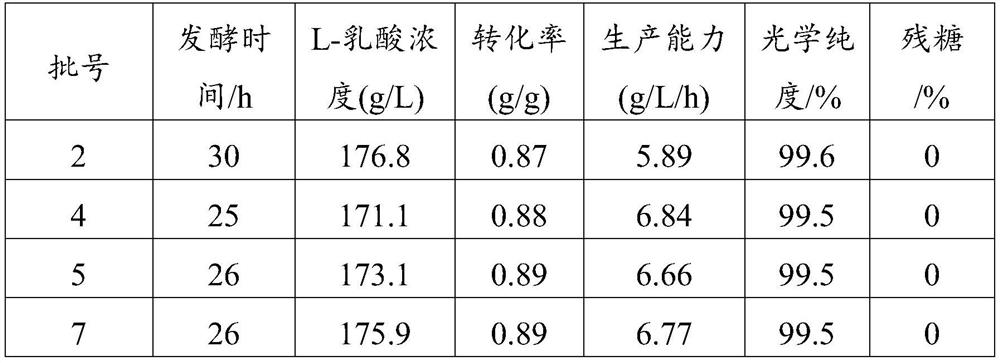

[0099] The test results of embodiment 2 and embodiment 3 are shown in table 1:

[0100] Table 1

[0101]

[0102] From Examples 2-3 and performance tests, it can be seen that the Bacillus coagulans provided by the present invention can be used to prepare L-lactic acid, and the single-batch fermentation method has an optimal production capacity of 7.3 g / L / h, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com