Method for effectively improving lactic acid fermentation of biomass

A lactic acid fermentation and biomass technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of fermentable sugar loss, increase the complexity and process cost of the biorefinery process, and achieve simplified production Improvement of process, lactic acid concentration and yield, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

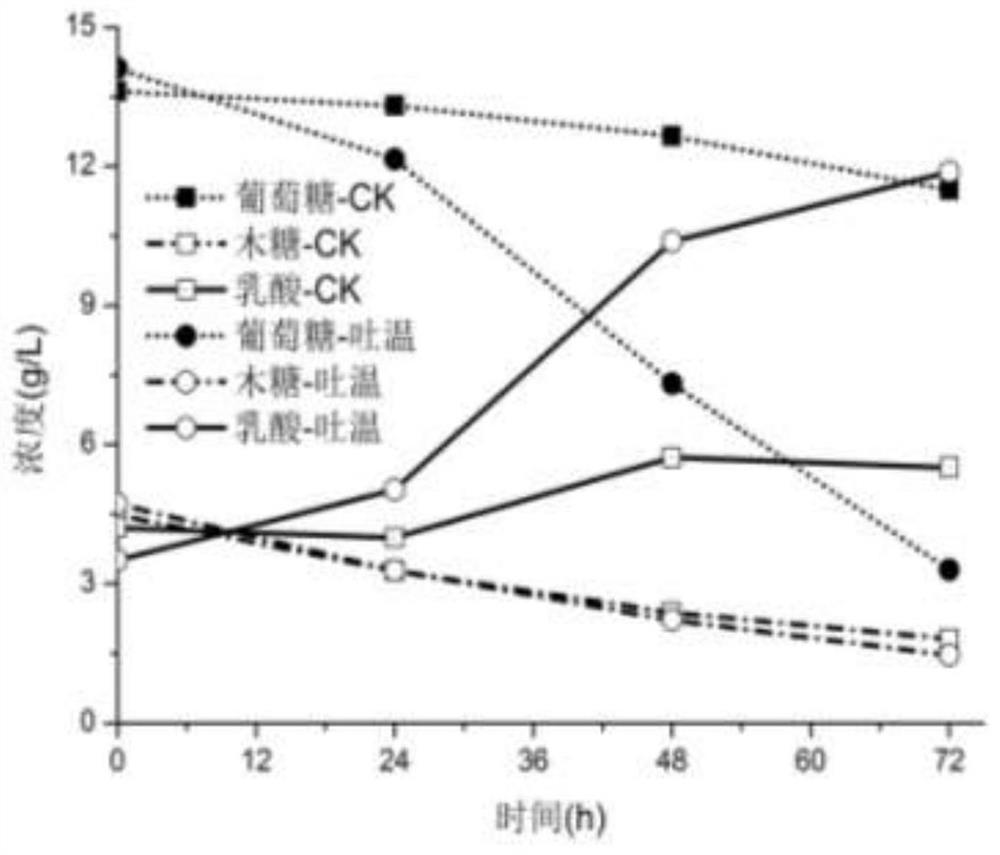

[0051] Example 1 Influence of the addition of Tween on the fermentation of corn stover hydrolyzate to produce lactic acid

[0052] The pulverized corn stalks (20-80 mesh) and phosphorus pentoxide were mixed and ball-milled at a mass ratio of 5g / 0.4g for 30min, heat-treated at 140°C for 60min, and hydrolyzed with water at a solid-liquid ratio of 10wt% at 215°C for 45min to obtain hydrolysis. Liquid, filtered and used for later use, its main components are cellobiose 1.82g / L, glucose 21.56g / L, xylose 6.29g / L, 1.6-anhydroglucose 0.76g / L, 5-HMF 2.68g / L, furfural 4.31 g / L, acetic acid 2.70g / L. Add the following nutrients to the corn stover hydrolyzate to prepare the fermentation medium (biomass hydrolyzate fermentation medium) of the corn stover hydrolyzate: casein peptone 10.0g / L, beef extract 10.0g / L, yeast powder 10.0g / L, disodium hydrogen phosphate 4.0g / L, diammonium citrate 4.0g / L, Tween 801.0g / L, K 2 HPO 4 4.0g / L, MgSO 4 .7H 2 O 0.58g / L, MnSO 4 .H 2 O 0.25g / L, CaCO 3...

Embodiment 2

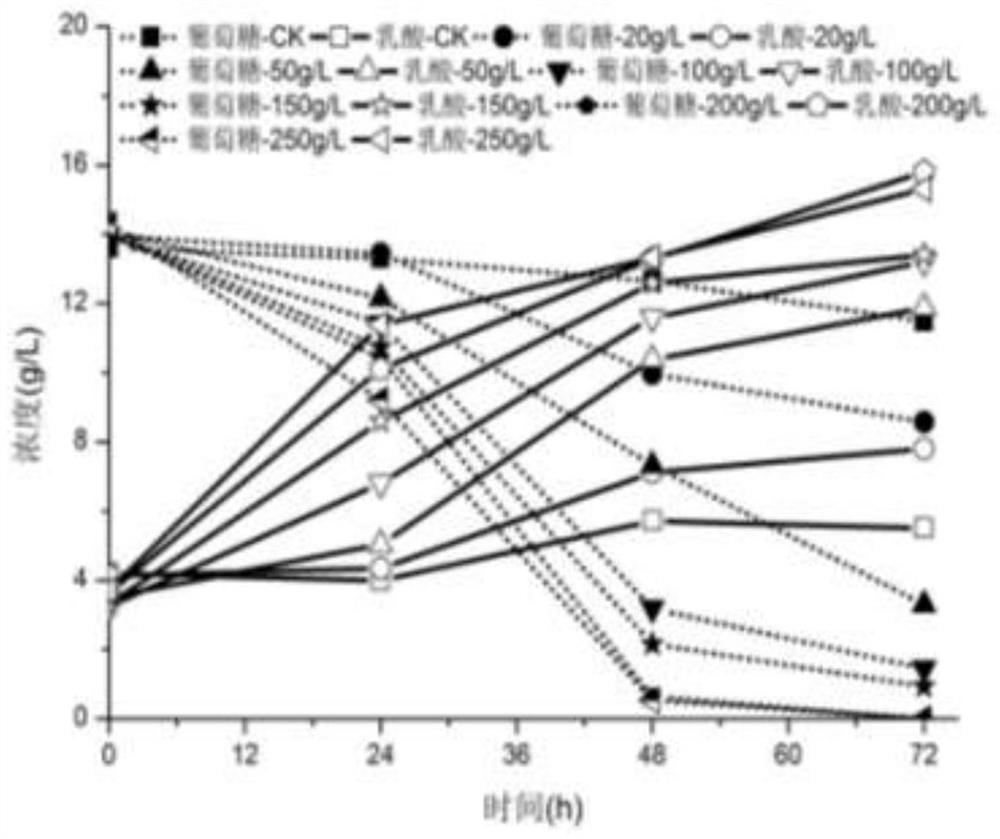

[0054] Example 2 The effect of different Tween concentrations on the fermentation of corn stover hydrolyzate to produce lactic acid

[0055] The seed solution of Pediococcus pentosaceus was 10% (V / V) inoculum (the number of cells in the fermentation broth after inoculation was 4.0*10 6 cell / mL) were respectively transferred to no Tween 80 (0 g / L) and additionally added different final concentrations ( In the experimental group of Tween-80 of 20g / L, 50g / L, 100g / L, 150g / L, 200g / L, 250g / L), the experiment group was incubated with constant temperature shaking on a shaking table at 37°C and 180rpm. The comparison of glucose consumption and lactic acid conversion in the experimental group is shown in Table 1, and the comparison of glucose and lactic acid changes in the fermentation process is shown in Table 1. figure 2 As shown, after 72h fermentation, the control group without adding Tween-80 can only consume 2.12g / L glucose to produce 1.51g / L lactic acid, while the fermentation ...

Embodiment 3

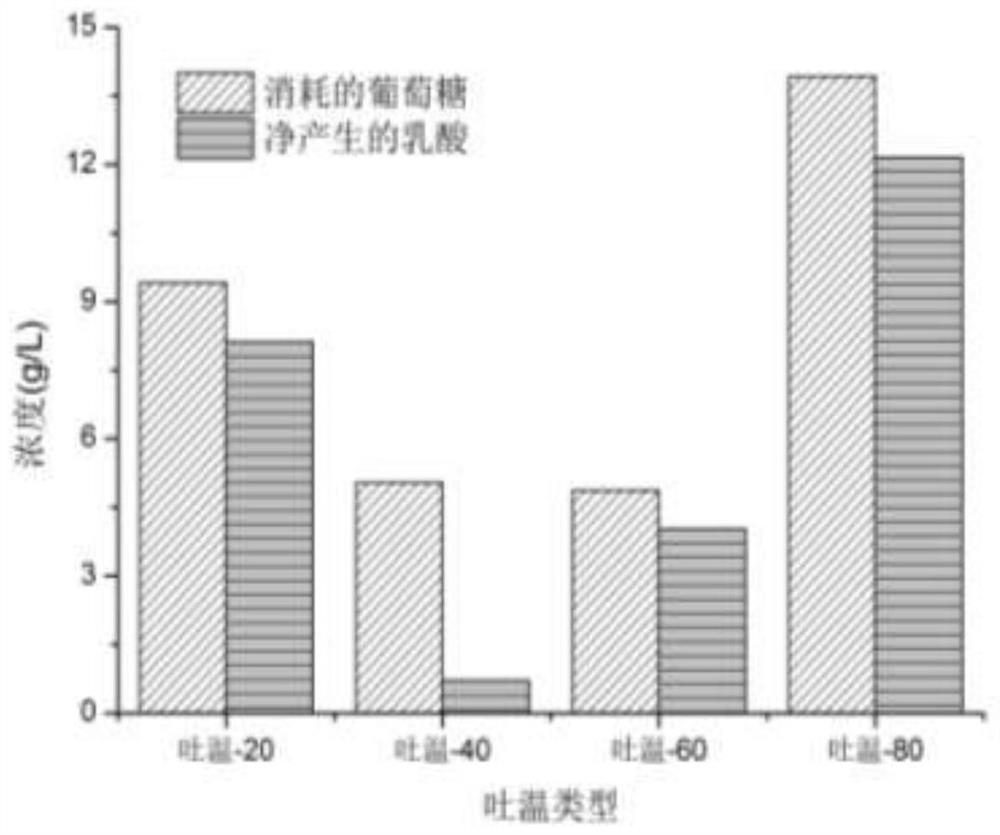

[0058] Example 3 Effects of different Tween types on the fermentation of corn stover hydrolyzate to produce lactic acid

[0059] The seed solution of Pediococcus pentosaceus was 10% (V / V) inoculum (the number of cells in the fermentation broth after inoculation was 4.0*10 6 Cell / ml) is transferred to the fermentation medium of corn straw hydrolysis liquid (which compositions in the same example 1), respectively. -40, Tween-60 or Tween-80) experimental groups were cultured with constant temperature shaking on a shaking table at 37°C and 180 rpm, and the glucose consumption and growth were detected by sampling regularly. The effect of different types of Tween on the fermentation of lactic acid by corn stover hydrolyzate such as image 3 As shown, under the action of Tween-40 and Tween-60 in the first 24h, the bacteria could consume 7.23g / L of glucose to produce 0.43g / L and 1.58g / L of lactic acid, respectively, and the fermentation stagnated after 24h. However, Tween-20 and Twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com