Method for efficiently producing lactic acid from non-enzymatic biomass hydrolysis saccharification liquid without detoxification

A biomass and saccharification solution technology, applied in the direction of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., can solve the problems that bacteria are difficult to adapt to the fermentation system, and the composition of biomass saccharification solution is complex, etc., to achieve Good inhibitor tolerance, shortened production cycle, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

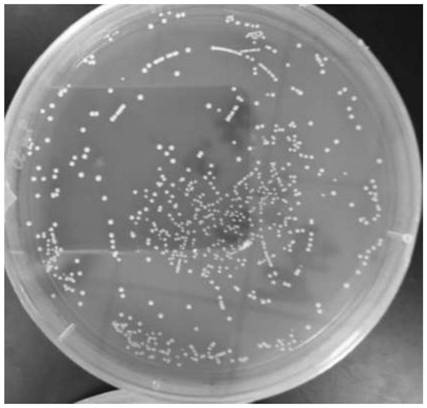

[0049] Example 1 Rice husk dregs hydrolyzate domestication experiment of Pediococcus pentosaceae

[0050] (1) Preparation of non-enzymatic rice husk hydrolysis saccharification liquid: rice husk (obtaining method: 150g rice husk and 150g deionized water (containing 5wt% H 3 PO 4 ) into a pressure-sealed stainless steel hydrolysis reactor, keep it under saturated steam at 205-210°C for 30 minutes, then open the valve quickly, filter the collected wet rice husk under pressure, and then dry it at room temperature under ventilated conditions until the water quality The content is less than 10%. ) mixed with phosphorus pentoxide at a mass ratio of 20:1 and ball-milled for 30 minutes, heat-treated at 140°C for 60 minutes, hydrolyzed at 215°C for 45 minutes at a solid-to-liquid ratio of 10wt% (g / ml) to obtain a hydrolyzed saccharification slurry, and the saccharification slurry was The rice husk slag hydrolysis and saccharification liquid is obtained by solid-liquid separation, and...

Embodiment 2

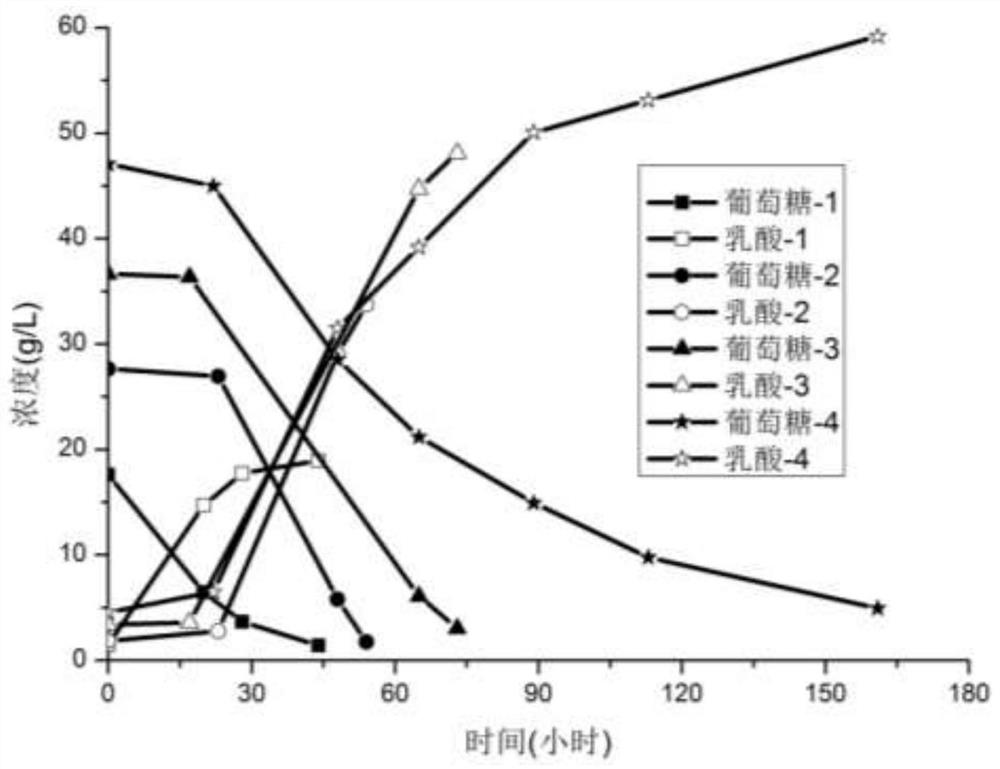

[0056] Example 2 Fermentation of wild bacteria and domesticated bacteria A to produce lactic acid from hydrolysis and saccharification liquid of rice husk dregs-batch fermentation comparative experiment

[0057] Single colonies of wild bacteria and domesticated bacteria A were inoculated into seed medium for overnight culture to obtain seed liquid, and the seed liquid was transferred to rice husk residue hydrolysis and saccharification liquid at 37 ℃, 180rpm shaker constant temperature shaking culture fermentation, the comparison of the growth trend is as follows Figure 4 As shown, the wild bacteria grow slowly, the cell density is small, and the highest OD value is only 12.90, while the domesticated bacteria A has a large cell density, and the highest OD value can reach 18.06. The changes of substrate products in the fermentation broth are as follows: Figure 5 As shown, the wild bacteria can slowly consume glucose in the first 42 hours, the highest concentration of lactic ...

Embodiment 3

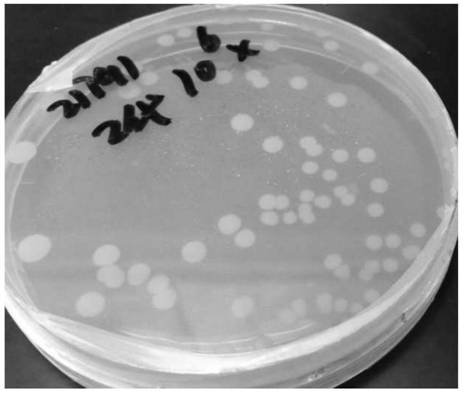

[0058] Example 3 High-concentration glucose re-acclimated Pediococcus pentosaceae fermented rice husk residue hydrolyzate experiment

[0059] Because domesticated bacterium A is slower to the utilization rate of glucose in the hydrolyzate, therefore utilize similar domesticated method to increase its glucose concentration (50g / L, 80g / L, 108g / L, 137g / L, 162g / L, 204g / L L) is domesticated and cultivated again in the re-acclimated fermentation medium to accelerate its utilization of glucose and strengthen its adaptability to acetic acid and lactic acid. First, the seed solution of domesticated bacteria A was transferred to the re-acclimation medium with an initial glucose concentration of 50g / L at an inoculum of 10% for cultivation, and then transferred to glucose with an inoculum of 10% after the glucose was exhausted. Concentration is 80g / L acclimatization culture in the acclimatization medium, so method until initial glucose concentration is the acclimatization medium of 204g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com