A kind of shirt fabric and preparation method thereof

A technology for fabrics and shirts, applied in the field of multifunctional shirting fabrics and their preparation, can solve the problems of short duration of efficacy, inability to bond fibers, and poor bonding, and achieve low production cost, light quality, and improved bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

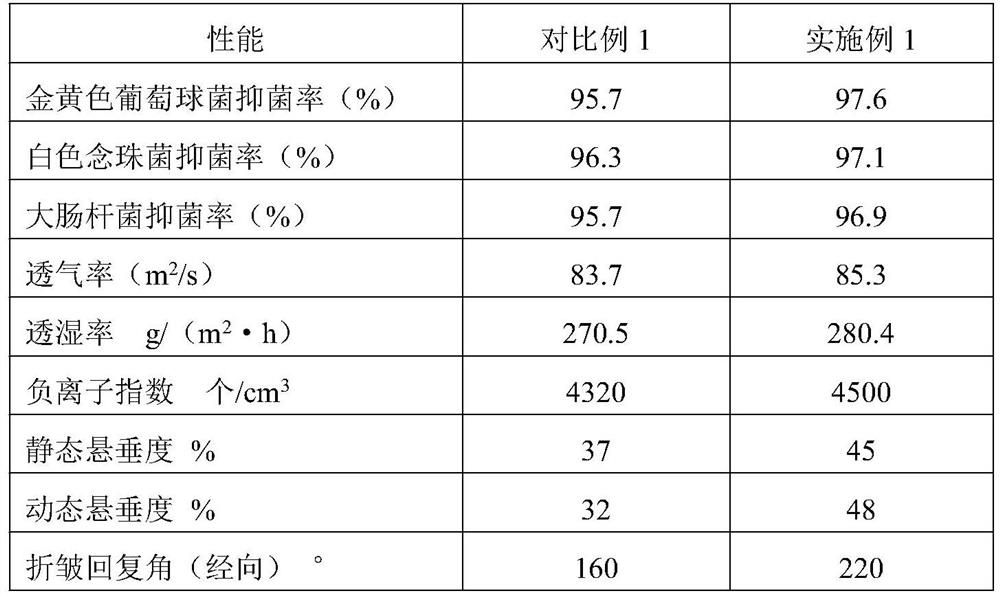

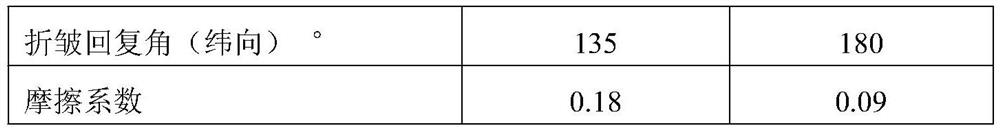

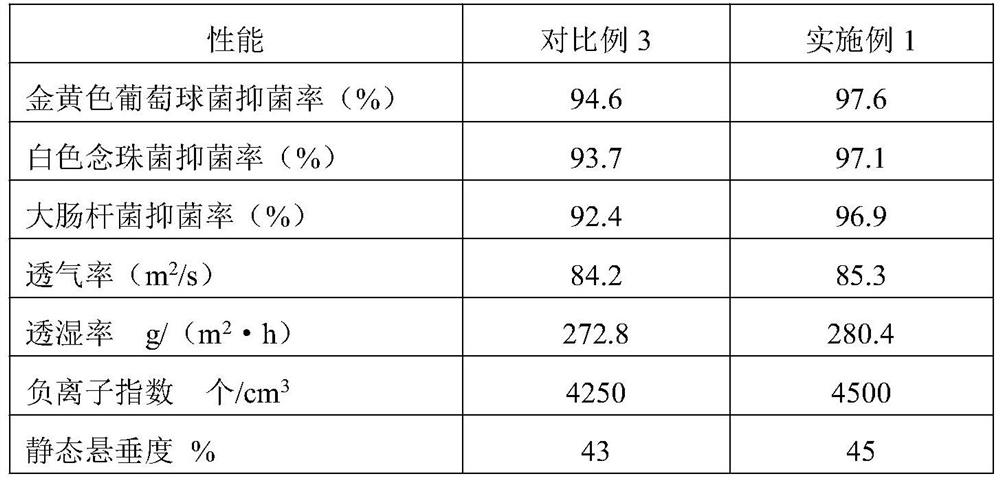

Examples

Embodiment 1

[0028] S1: Take polyethylene terephthalate particles and put them into the reactor, heat and melt at 220°C for 20 minutes; then cool down to 150°C, add polyethylene terephthalate 8% by mass Vinylpyrrolidone and 25% polyethylene glycol were stirred and reacted for 4.5 hours; then ethanol accounting for 20% by mass of polyethylene terephthalate was added, and ultrasonically stirred for 30 minutes; centrifuged to obtain a porous polymer;

[0029] S2: Heat and melt the porous polymer in step S1 to form an electrospinning liquid; take three parts and pour them into the first micropump, the second micropump, and the third micropump respectively, and control the diameter of the first micropump to 0.4mm, and the second micropump. The diameter of the micropump is 0.8mm, and the coaxial nozzle with the diameter of the third micropump is 0.3mm as the spinneret for spraying thin streams, wherein the spinning temperature is 25°C, the humidity is 40%RH, and the extrusion speed of the first mic...

Embodiment 2

[0035] S1: Take polyethylene terephthalate particles and add them to the reactor, heat and melt at 250°C for 40 minutes; then cool down to 170°C, and add polyethylene terephthalate with a mass ratio of 16%. Vinylpyrrolidone and 35% polyethylene glycol were stirred and reacted for 6 hours; then, ethanol accounting for 40% by mass of polyethylene terephthalate was added, and ultrasonically stirred for 60 minutes; centrifuged to obtain a porous polymer;

[0036] S2: Heat and melt the porous polymer in step S1 to form an electrospinning liquid; take three parts and pour them into the first micropump, the second micropump, and the third micropump respectively, and control the diameter of the first micropump to 0.6mm, and the second micropump. The diameter of the micropump is 1.2mm, and the coaxial nozzle with the diameter of the third micropump is 0.7mm as the spinneret for jetting thin streams, wherein the spinning temperature is 45°C, the humidity is 60%RH, and the extrusion speed...

Embodiment 3

[0042] S1: Take polyethylene terephthalate particles and add them to the reactor, heat and melt at 235°C for 30 minutes; then cool down to 165°C, add polyethylene terephthalate 12% by mass Vinylpyrrolidone and 30% polyethylene glycol, stirred and reacted for 4.5h; then added ethanol accounting for 35% by mass of polyethylene terephthalate, and ultrasonically stirred for 45min; centrifuged to obtain a porous polymer;

[0043] S2: Heat and melt the porous polymer in step S1 to form an electrospinning solution; take three parts and pour them into the first micropump, the second micropump, and the third micropump respectively, and control the diameter of the first micropump to 0.5mm, and the second micropump. The diameter of the micropump is 1.1mm, and the coaxial nozzle with the diameter of the third micropump is 0.4mm as the spinneret for spraying fine streams, wherein the spinning temperature is 40°C, the humidity is 55%RH, and the extrusion speed of the first micropump is The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com