Methylstyrene multi-component copolymer composite microsphere as well as preparation method and application thereof

A technology of methyl styrene and multiple copolymers, which is applied in the field of composite microspheres of methyl styrene multiple copolymers and its preparation, can solve the problems of polymer surface pollution and environmental pollution, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Add 10.5g of maleic anhydride, 0.91g of azobisisobutyronitrile, 5g of divinylbenzene, 11.8g of α-methylstyrene and 80g of isoamyl acetate into a 500mL three-necked flask. After the materials are mixed evenly, blow nitrogen gas for 20 Minutes, move the three-necked flask into a 70°C water bath, react for 3 hours, then add 2.58g of vinyl acetate and 3.12g of styrene to the three-necked flask, and continue to react for 2 hours. After the reaction is completed, pass the obtained polymer emulsion suspension through a centrifuge to After centrifugation at 2000 rad / min for 20 minutes, 15.07 g of polymer solid A1 was obtained, corresponding to a polymer yield of 55.2%.

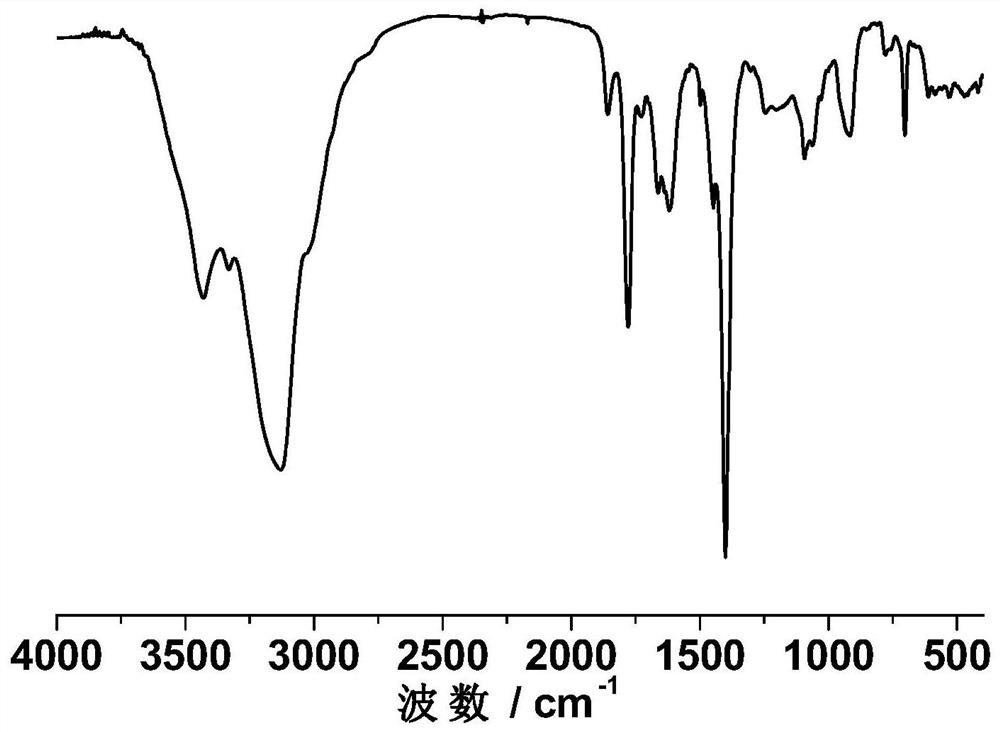

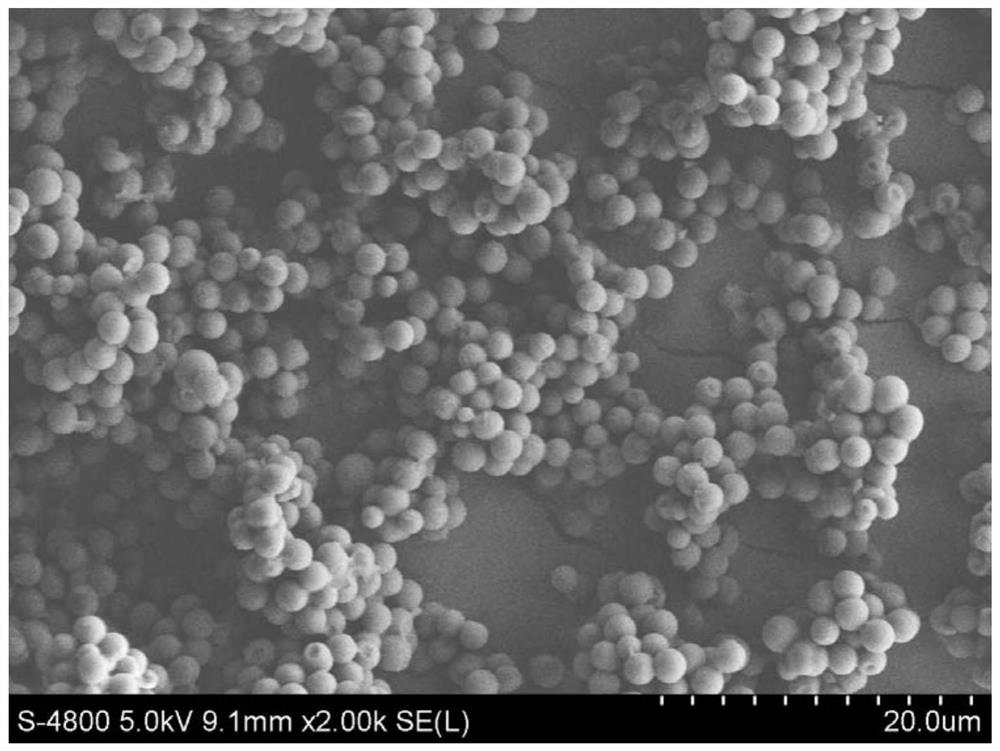

[0085] After testing, the particle size of the polymer microspheres measured at the end of the first step reaction was 1700 nanometers, and the particle size of the polymer microspheres was 2000 nanometers at the end of the first polymerization reaction. The electron microscope photo shows that the polymer is a ...

Embodiment 2

[0089] Add 11g of maleic anhydride, 0.9g of azobisisobutyronitrile, 0.5g of divinylbenzene, 11.8g of α-methylstyrene and 70g of butyl benzoate into a 500mL three-necked flask. Minutes, move the three-necked flask into a 70°C water bath, react for 3 hours, then add 1.72g vinyl acetate and 2.08g styrene to the three-necked flask, continue to react for 2 hours, after the reaction is completed, pass the obtained polymer emulsion suspension through a centrifuge to Centrifuge at 2000 rad / min for 20 minutes to obtain 12.55 g of polymer solid A2, corresponding to a polymer yield of 49.4%.

[0090] After testing, the particle diameter of the polymer microspheres is 1200 nanometers. The core of the resulting polymer microspheres is a cross-linked polymer of maleic anhydride and α-methylstyrene, and the shell is a linear polymerization of α-methylstyrene, styrene, vinyl acetate, and maleic anhydride things. The molar ratio of maleic anhydride to α-methylstyrene in the core is 1:0.9, th...

Embodiment 3

[0092] Add 9g of maleic anhydride, 0.7g of azobisisobutyronitrile, 1.5g of divinylbenzene, 10g of α-methylstyrene and 87.8g of butyl butyrate into a 500mL three-necked flask. Minutes, move the three-necked flask into a 70°C water bath, react for 3 hours, then add 2.15g vinyl acetate and 2.6g styrene to the three-necked flask, continue to react for 2 hours, after the reaction is completed, pass the obtained polymer emulsion suspension through a centrifuge to After centrifugation at 2000 rad / min for 20 minutes, 15.76 g of polymer solid A3 was obtained, corresponding to a polymer yield of 59.8%.

[0093] After testing, the particle diameter of the polymer microspheres is 1400 nanometers. The core of the resulting polymer microspheres is a cross-linked polymer of maleic anhydride and α-methylstyrene, and the shell is a linear polymerization of α-methylstyrene, styrene, vinyl acetate, and maleic anhydride thing. The molar ratio of maleic anhydride to α-methylstyrene in the core i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com