Treatment method of chlorine-containing volatile organic compound waste gas

A technology of volatile organic compounds and treatment methods, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of secondary pollution, long absorption time, etc., and achieve good recycling, low cost, and high absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

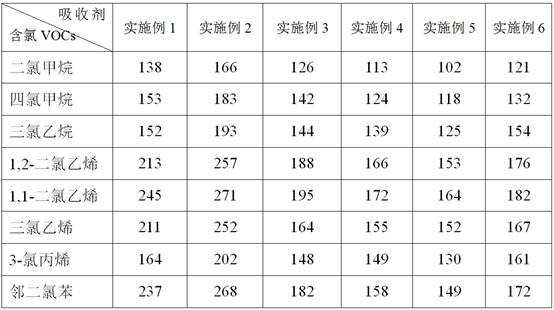

Examples

Embodiment 1

[0023] Weigh choline chloride and ethylene glycol according to a molar ratio of 1:2 and add them to the reactor, stir at 80°C and 150r / min for 1 hour, then cool to room temperature to obtain a transparent choline chloride / ethylene glycol compound solvent. Absorb the gas containing chloroform and the above composite solvent in the absorption tower, control the absorption temperature to 25°C, the absorption pressure to 0.1MPa, and the liquid-gas ratio to 4L / m 3 . After the absorption reaches equilibrium, the weight before and after absorption is detected by gravimetric method, and the chloroform absorbed by each gram of absorbent is calculated to be 147mg.

[0024] The rich absorbent with absorption balance is regenerated by heating, the heating temperature is 100°C, the pressure is 0.1MPa, and the regeneration time is 1h. After 10 cycles of absorption and desorption, the regenerated absorbent was used to absorb chloroform-containing gas under the same operating conditions, an...

Embodiment 2

[0026] Weigh choline chloride and ethylene glycol according to a molar ratio of 1:4 and add them to the reactor, stir at 60°C and 150r / min for 1 hour, then cool to room temperature to obtain a transparent choline chloride / ethylene glycol compound solvent. Absorb the gas containing chloroform and the above composite solvent in the absorption tower, control the absorption temperature to 15°C, the absorption pressure to 0.3MPa, and the liquid-gas ratio to 5L / m 3 . After the absorption reaches equilibrium, the weight before and after absorption is detected by gravimetric method, and the chloroform absorbed by each gram of absorbent is calculated to be 217 mg.

[0027] The rich absorbent with absorption balance is regenerated by heating and reducing pressure, the heating temperature is 120°C, the pressure is 0.01MPa, and the regeneration time is 20min. After 10 cycles of absorption and desorption, the regenerated absorbent was used for the absorption of gas containing chloroform ...

Embodiment 3

[0029] Weigh choline chloride and ethylene glycol at a molar ratio of 1:6 and add them to the reactor, stir at 100°C and 150r / min for 1 hour, then cool to room temperature to obtain a transparent choline chloride / ethylene glycol compound solvent. Absorb the gas containing chloroform and the above composite solvent in the absorption tower, control the absorption temperature to 40°C, the absorption pressure to 0.1MPa, and the liquid-gas ratio to 3L / m 3 . After the absorption reaches equilibrium, the weight before and after absorption is detected by gravimetric method, and the chloroform absorbed by each gram of absorbent is calculated to be 115 mg.

[0030] The rich absorbent with absorption balance is decompressed and regenerated, the pressure is 0.01MPa, and the desorption time is 30min. After 10 cycles of absorption and desorption, the regenerated absorbent was used for the absorption of gas containing chloroform under the same operating conditions, and the amount of chloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com