Composite ferromanganese-based Prussian blue material and its preparation method and application

A composite ferromanganese-based, Prussian blue technology, applied in nanotechnology, ferricyanide, structural parts, etc. for materials and surface science, can solve the problem that the stability of materials has not been significantly improved and the precipitation reaction speed varies greatly , uniform mixing and other issues, to achieve the effect of improving cycle stability and rate performance, easy large-scale operation, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

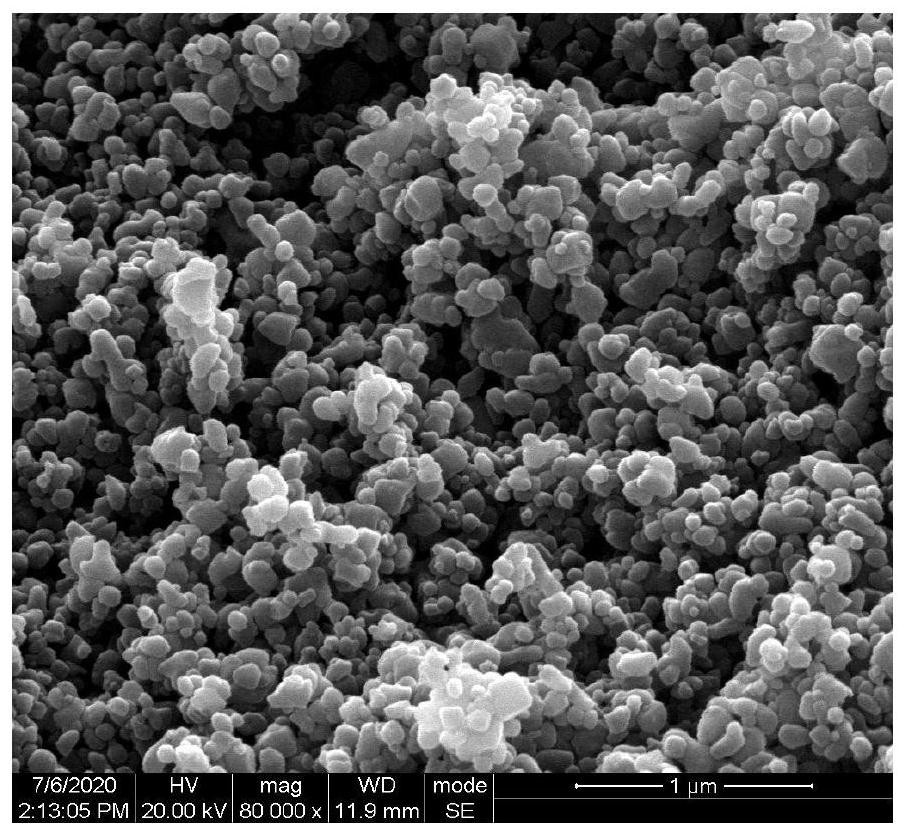

[0103] A composite ferrocyanide-based Prussian blue material in which sodium ferrocyanide manganese is a matrix phase and cesium ferrocyanide manganese is a quantum dot stable phase, and is used to prepare a positive electrode material for a sodium ion battery. The specific preparation process is as follows:

[0104] A. Prepare 21mL solution A containing 0.2M sodium ferrocyanide decahydrate, 2g / L PVP, 2.8M sodium chloride and 0.04M cesium nitrate, and keep the temperature of solution A at 25°C;

[0105]B. Prepare 9 mL of solution B containing 0.7M manganese sulfate monohydrate, and keep the temperature of solution B at 25°C;

[0106] C. Drop solution B into solution A at a rate of 1mL / min, keep warm at 25°C for 19h, after the reaction, wash and separate the precipitate several times, and finally dry it in an ordinary oven at 80°C for 12h to obtain sub Cesium manganese ferricyanide sodium Prussian blue material.

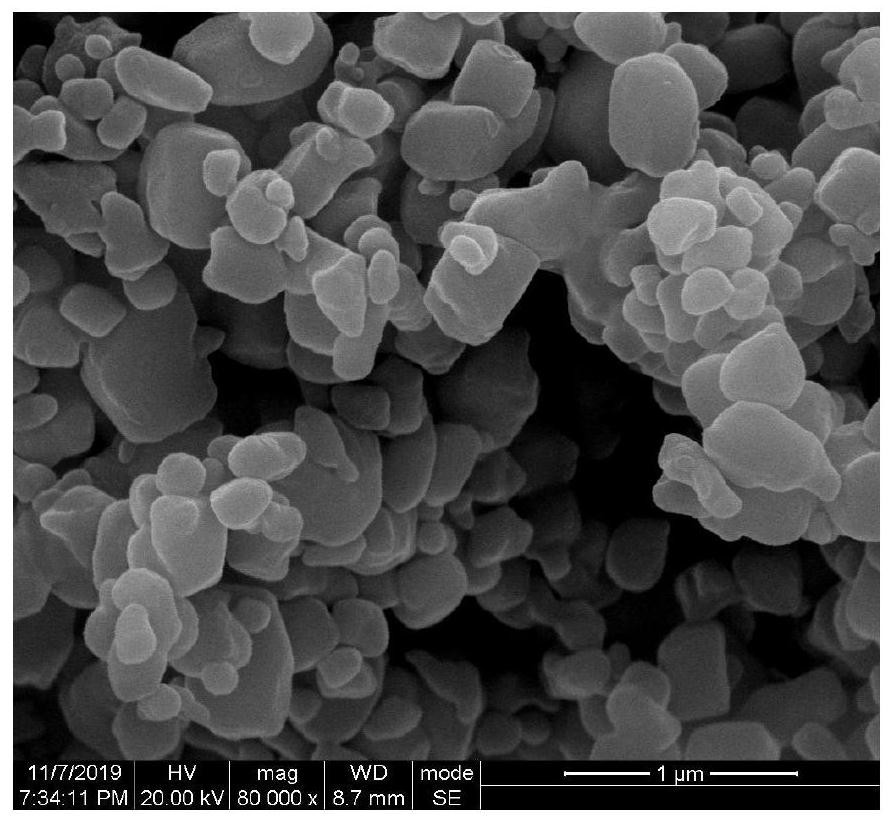

[0107] For comparison, a single-phase sodium ferrocyanide manga...

Embodiment 2

[0118] A composite ferrocyanide-based Prussian blue material in which cesium ferrocyanide manganese cesium is a matrix phase and sodium ferrocyanide manganese is a quantum dot, and its specific preparation process is as follows:

[0119] A. Prepare 33 mL of solution A containing 0.03M sodium ferrocyanide decahydrate, 1.2M sodium citrate decahydrate and 0.075M cesium nitrate, and keep the temperature of solution A at 85°C;

[0120] B. Prepare 17 mL of solution B comprising 0.06M manganese sulfate monohydrate, 1.2M sodium citrate decahydrate and 0.075M cesium nitrate, and keep the temperature of solution B at 85°C;

[0121] C. Drop solution B into solution A at a rate of 1mL / min, keep warm at 85°C for 24h, after the reaction, cool, wash and separate the precipitate several times, and finally dry it in an ordinary oven at 80°C for 12h , Cesium ferrocyanide manganese sodium Prussian blue material.

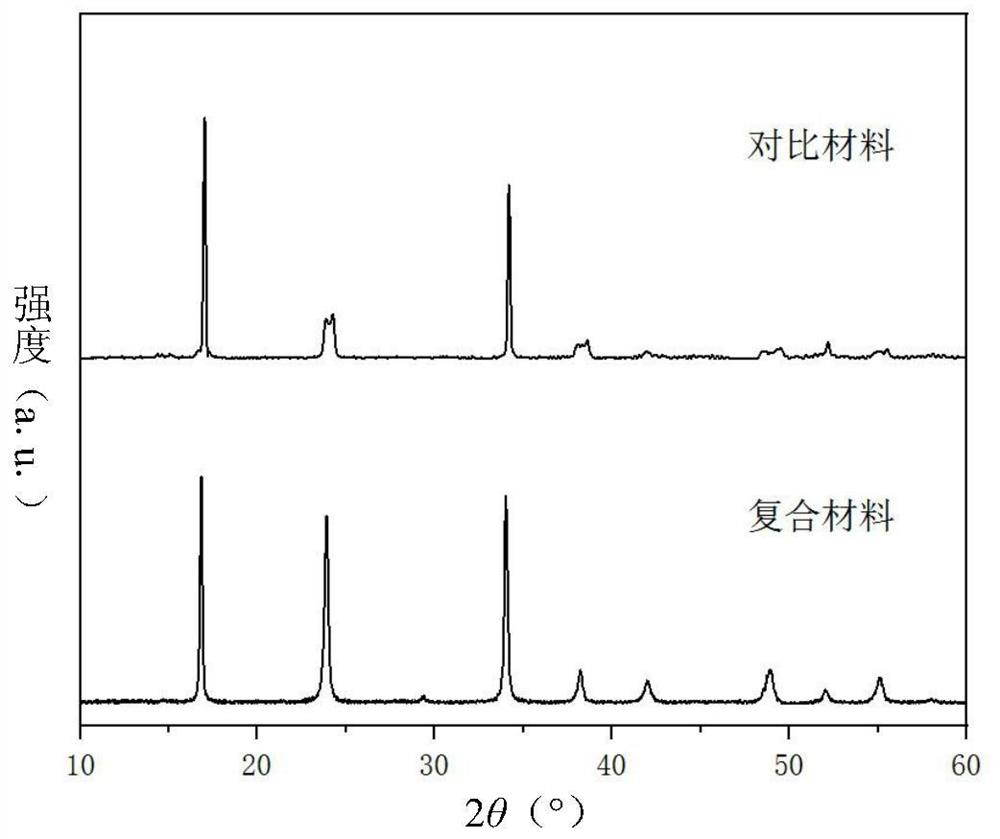

[0122] Figure 10 It is the X-ray diffraction spectrum of the composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com