Culture method of low-temperature anaerobic sludge

An anaerobic sludge and cultivation method technology, which is applied in the direction of sludge treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problems of substandard effluent, unsuitable for high-concentration sewage, long cultivation time, etc., and achieve reduction Guaranteed operating cost, sewage treatment effect, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

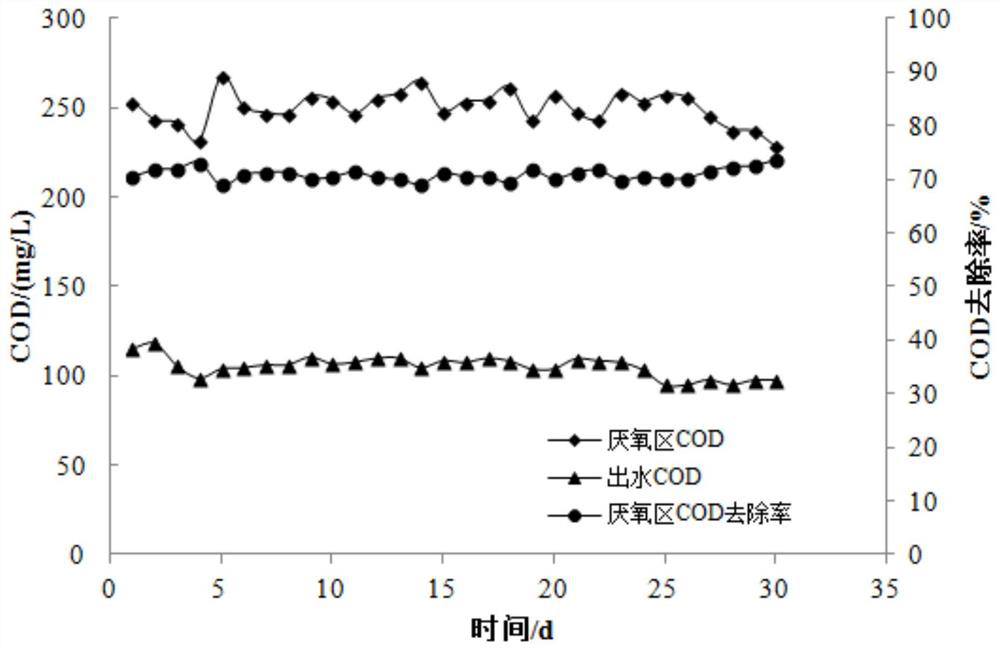

Image

Examples

Embodiment 1

[0035] (1) Enrichment culture, the activated sludge obtained in the chemical wastewater treatment process and the bottom sludge of buried septic tanks in northern rural areas were respectively inserted into the enrichment medium for enrichment culture; The weight accounts for 1% of the weight of the enriched medium, and the shaker is used for shaking culture, the rotation speed is 100rpm, and the temperature is room temperature; the composition ratio of the enriched medium includes: glucose 15g / L, peptone 2g / L, yeast extract powder 1g / L, L -Cysteine 0.5g / L, Sodium Chloride 3g / L, Dipotassium Hydrogen Phosphate 0.5g / L, Ammonium Sulfate 0.5g / L, Magnesium Sulfate 0.1g / L, Calcium Chloride 0.1g / L, Citric Acid Ferric ammonium 0.01g / L;

[0036] (2) Dehydration, after the sludge enrichment culture is completed, the enriched culture is centrifuged to obtain dehydrated enriched sludge; the rotational speed of the centrifugal operation is 4000rpm;

[0037] (3) Mixing, mixing dehydrated c...

Embodiment 2

[0045] (1) Enrichment culture, the activated sludge obtained in the chemical wastewater treatment process and the bottom sludge of buried septic tanks in northern rural areas were respectively inserted into the enrichment medium for enrichment culture; The weight accounts for 1% of the weight of the enriched medium, and the shaker is used for shaking culture, the rotation speed is 100rpm, and the temperature is room temperature; the composition ratio of the enriched medium includes: glucose 15g / L, peptone 2g / L, yeast extract powder 1g / L, L -Cysteine 0.5g / L, Sodium Chloride 3g / L, Dipotassium Hydrogen Phosphate 0.5g / L, Ammonium Sulfate 0.5g / L, Magnesium Sulfate 0.1g / L, Calcium Chloride 0.1g / L, Citric Acid Ferric ammonium 0.01g / L;

[0046] (2) Dehydration, after the sludge enrichment culture is completed, the enriched culture is centrifuged to obtain dehydrated enriched sludge; the rotational speed of the centrifugal operation is 4000rpm;

[0047] (3) Mixing, mixing, mixing de...

Embodiment 3

[0055] (1) Enrichment culture, the activated sludge obtained in the chemical wastewater treatment process and the bottom sludge of buried septic tanks in northern rural areas were respectively inserted into the enrichment medium for enrichment culture; The weight accounts for 1% of the weight of the enriched medium, and the shaker is used for shaking culture, the rotation speed is 100rpm, and the temperature is room temperature; the composition ratio of the enriched medium includes: glucose 15g / L, peptone 2g / L, yeast extract powder 1g / L, L -Cysteine 0.5g / L, Sodium Chloride 3g / L, Dipotassium Hydrogen Phosphate 0.5g / L, Ammonium Sulfate 0.5g / L, Magnesium Sulfate 0.1g / L, Calcium Chloride 0.1g / L, Citric Acid Ferric ammonium 0.01g / L;

[0056] (2) Dehydration, after the sludge enrichment culture is completed, the enriched culture is centrifuged to obtain dehydrated enriched sludge; the rotational speed of the centrifugal operation is 4000rpm;

[0057] (3) Mixing, mixing dehydrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com