Preparation method of organic fertilizer taking activated sludge as raw material

A technology of activated sludge and organic fertilizer, applied in the direction of organic fertilizer, sewage/sludge fertilizer, inorganic fertilizer, etc., to achieve the effect of increasing organic matter, strong resistance resistance, and significant effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

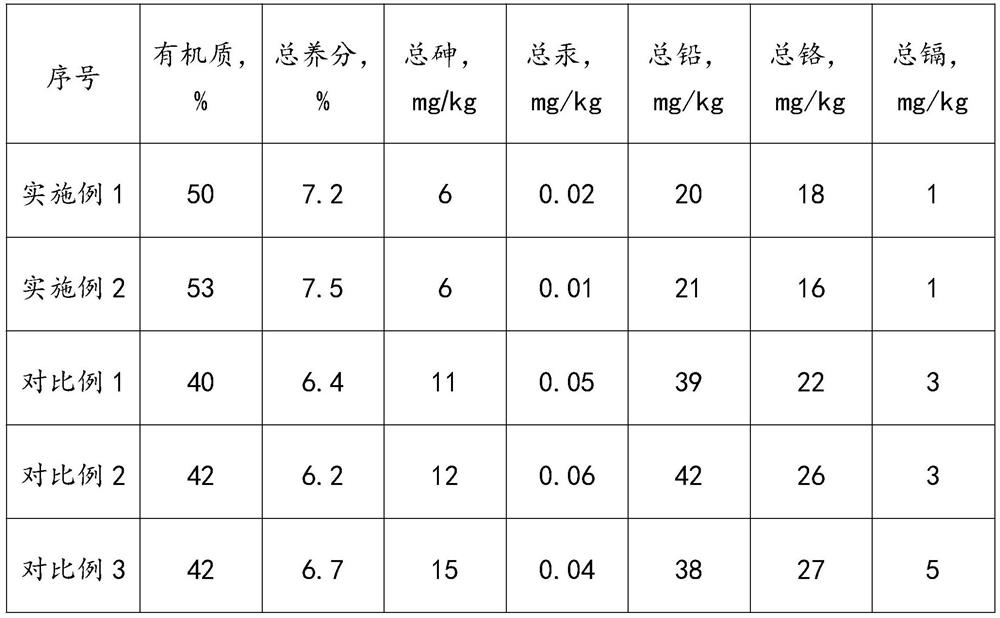

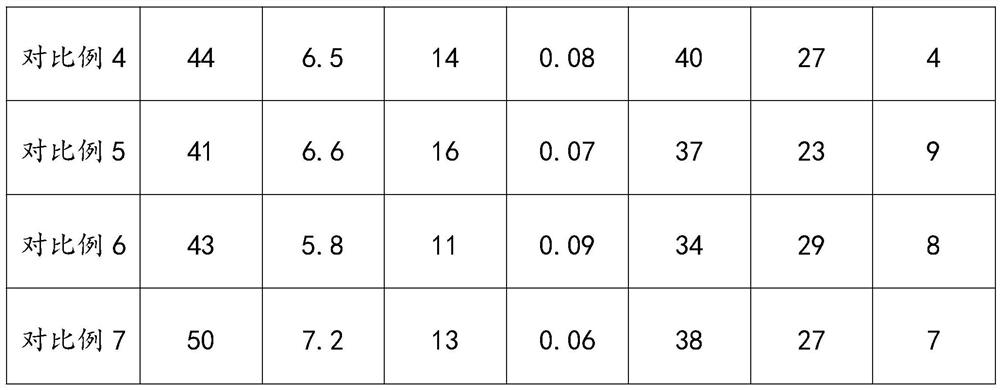

Examples

preparation example Construction

[0027] In one embodiment, the preparation method of the fermentation broth in step 1) comprises the following steps: making Bacillus licheniformis, Bacillus subtilis, Bacillus megaterium, Bacillus jelly-like, Lactobacillus acidophilus, phospholytic solution The slanted seeds of Bacillus megaterium and Bacillus thuringiensis were respectively inoculated into the seed culture medium, and cultivated for 12-24 hours at a temperature of 30-35°C and a rotation speed of 100-150r / min to obtain a seed liquid; the seed liquid Inoculate them into the liquid fermentation medium respectively, cultivate them for 24-36 hours at a temperature of 30-35°C and a rotational speed of 100-150r / min to obtain a fermentation broth, and mix the fermentation broths of different strains, Obtain the compound fermentation broth.

[0028] In one embodiment, the compound fermentation broth in the step 1) includes the following fermentation broth in parts by weight: 10-15 parts of Bacillus licheniformis ferme...

Embodiment 1

[0035] A kind of preparation method of the organic fertilizer that takes activated sludge as raw material is as follows:

[0036] 1) Weigh the following raw materials in proportion: 40 parts of activated sludge, 10 parts of molasses, 20 parts of bran shells, 30 parts of water, 5 parts of fermented bacteria liquid, 20 parts of humus soil, and 1 part of trace elements;

[0037] 2) Pulverizing the chaff and passing through an 80-mesh sieve to obtain chaff powder;

[0038] 3) Mix and stir the raw materials described in step 1) and the bran hull powder obtained in step 2) in proportion, the water content of the mixture is 35%, and form the mixture into a mixture pile with a width of 1m and a height of 1m. Fermentation, after fermentation to a temperature of 90°C, turn over and continue fermentation, repeat 3 times;

[0039] 4) Crushing and sieving the organic fertilizer after the fermentation is completed to obtain a finished organic fertilizer.

[0040] The preparation method of...

Embodiment 2

[0045] Same as Example 1, the difference is that the raw material is composed of the following components by weight: 60 parts of activated sludge, 15 parts of molasses, 25 parts of chaff, 45 parts of water, 8 parts of fermented bacteria liquid, 25 parts of humus, 5 parts of trace elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com