Thick-coating quick-drying cold-spraying zinc sealing agent and construction method thereof

A thick-coating, quick-drying, construction method technology, applied in the direction of coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of low content of organic additives, weak intermolecular forces, and reduced adhesion of primers. Achieve the effect of improving binding force, good physical properties and promoting compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

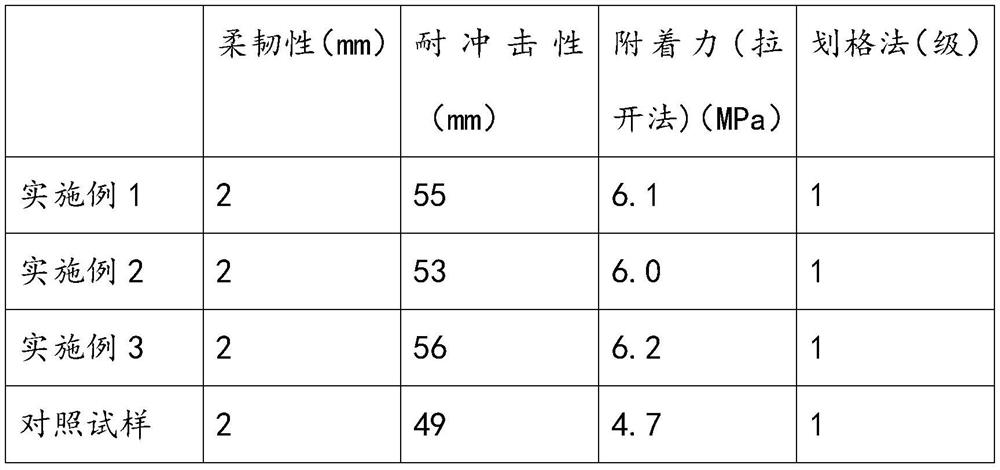

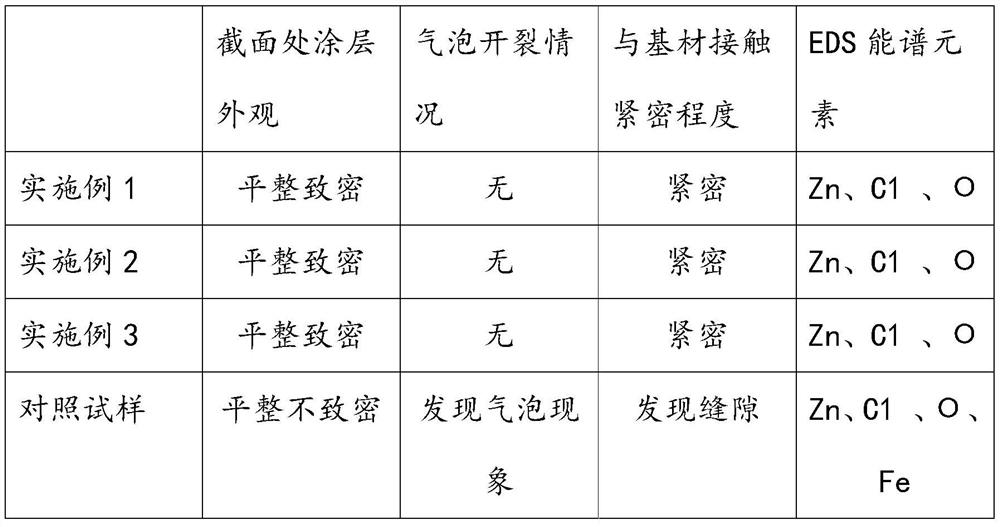

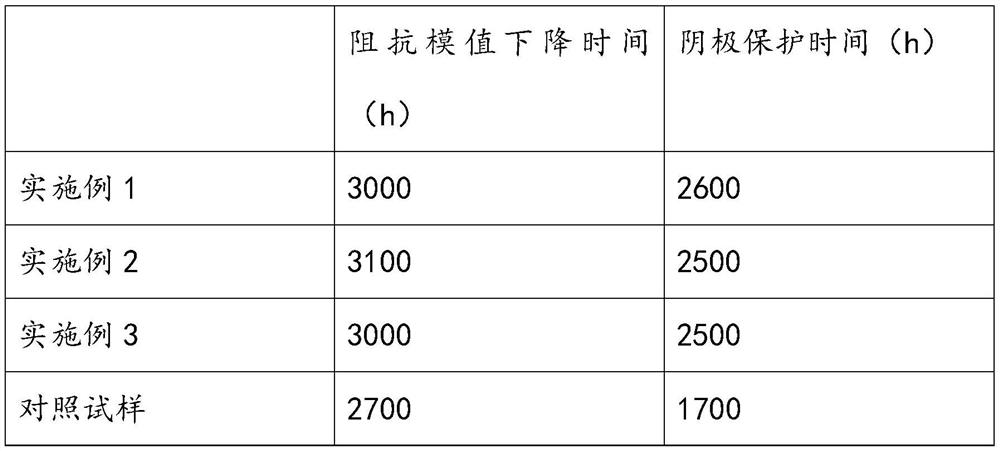

Examples

Embodiment 1

[0067] The A agent comprises the following components by mass fraction:

[0068] Phenol: 20 parts;

[0069] Paraformaldehyde: 35 parts;

[0070] Diethylenetriamine: 40 parts;

[0071] Thiourea: 20 parts;

[0072] Accelerator: 1 part;

[0073] The B agent comprises at least the following components by mass fraction:

[0074] Epoxy resin: 30 parts;

[0075] Solvent: 30 parts;

[0076] Toughening agent: 10 parts;

[0077] Thixotropic agent: 10 parts;

[0078] Cosolvent: 2 parts;

[0079] Colorant: 2 parts;

[0080] Defoamer: 1.5 parts;

[0081] Curing agent: 50 parts;

[0082] Supramolecular additives: 1 part.

[0083] In the above formula:

[0084] The accelerator is DMP-30; the epoxy resin is a mixture obtained by mixing 607 epoxy resin, 604 epoxy resin and 601 epoxy resin in a ratio of 1:2:3.

[0085] The solvent in Agent B is a mixture obtained by mixing xylene, n-butanol, and ethylbenzene in a ratio of 3:4:1;

[0086] The thixotropic agent is hydrogenated cast...

Embodiment 2

[0096] Thick-coated quick-drying cold-spray zinc sealer,

[0097] Including Agent A and Agent B;

[0098] The A agent comprises the following components by mass fraction:

[0099] Phenol: 30 parts;

[0100] Paraformaldehyde: 25 parts;

[0101] Diethylenetriamine: 40 parts;

[0102] Thiourea: 20 parts;

[0103] Accelerator: 2 parts;

[0104] The B agent comprises at least the following components by mass fraction:

[0105] Epoxy resin: 50 parts;

[0106] Solvent: 60 parts;

[0107] Toughening agent: 20 parts;

[0108] Thixotropic agent: 20 parts;

[0109] Co-solvent: 0.5 part;

[0110] Colorant: 1 part;

[0111] Defoamer: 0.5 parts;

[0112] Curing agent: 20 parts;

[0113] Supramolecular additives: 0.1 part.

[0114] In the above formula:

[0115] The accelerator is DMP-30; the epoxy resin is a mixture obtained by mixing 607 epoxy resin, 604 epoxy resin and 601 epoxy resin in a ratio of 1:2:3.

[0116] The solvent in Agent B is a mixture obtained by mixing xyle...

Embodiment 3

[0127] Thick-coated quick-drying cold-spray zinc sealer,

[0128] Including Agent A and Agent B;

[0129] The A agent comprises the following components by mass fraction:

[0130] Phenol: 25 parts;

[0131] Paraformaldehyde: 30 parts;

[0132] Diethylenetriamine: 35 parts;

[0133] Thiourea: 22 parts;

[0134] Accelerator: 1.5 parts;

[0135] The B agent comprises at least the following components by mass fraction:

[0136] Epoxy resin: 40 parts;

[0137] Solvent: 45 parts;

[0138] Toughening agent: 15 parts;

[0139] Thixotropic agent: 15 parts;

[0140] Co-solvent: 1.5 parts;

[0141] Colorant: 1.5 parts;

[0142] Defoamer: 1 part;

[0143] Curing agent: 40 parts;

[0144] Supramolecular additives: 0.7 parts.

[0145] In the above formula:

[0146] The accelerator is DMP-30; the epoxy resin is a mixture obtained by mixing 607 epoxy resin, 604 epoxy resin and 601 epoxy resin in a ratio of 1:2:3.

[0147] The solvent in Agent B is a mixture obtained by mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com