Brand-new CFB boiler furnace outlet non-metal expansion joint

A boiler furnace and non-metallic technology, applied in the sealing of the engine, the fuel burned in the molten state, and the treatment of combustion products, etc., can solve the problems of increased power consumption, lower flue gas temperature at the outlet of the furnace, and increased output of induced draft fans, etc. , so as to reduce the possibility of burning loss, prevent the backflow of flue gas and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

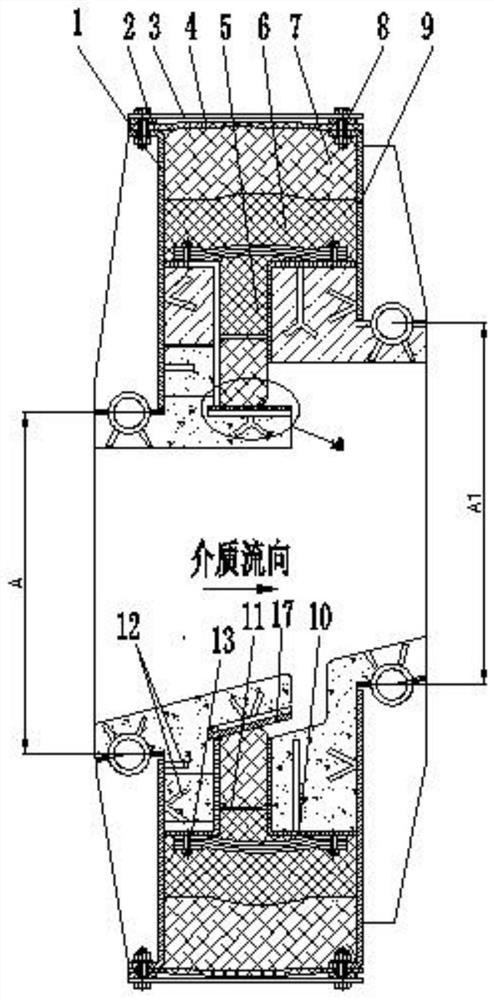

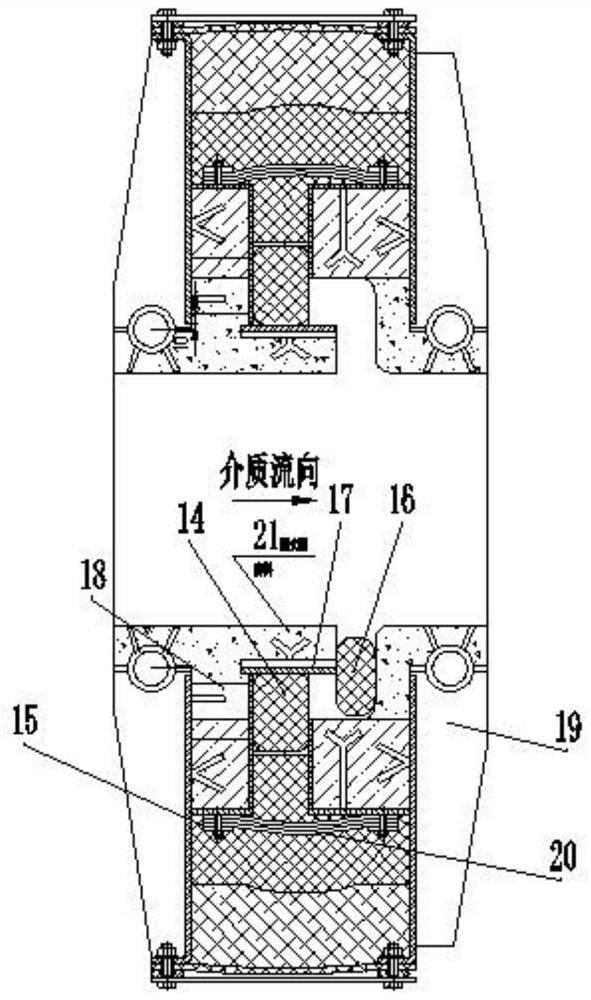

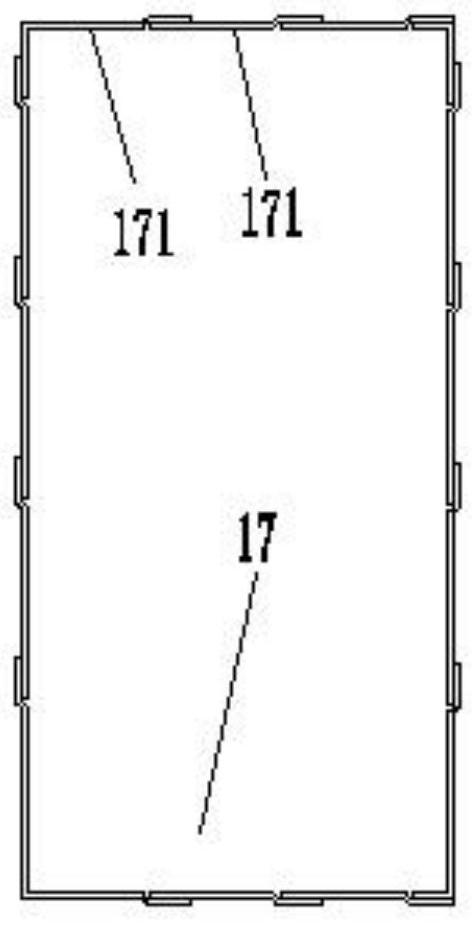

[0033] Such as figure 1 , figure 2 As shown, a brand-new non-metallic expansion joint at the furnace outlet of a CFB boiler includes correspondingly set metal frame 1 and metal frame 9. The outer end of the metal frame 29 is folded at right angles to the left to form a platform, and the two ends of the combined retaining ring 4 made of heat-resistant composite material are respectively placed on the leftward-turned platform of the metal frame 1 1 and the metal frame 2 9 is turned leftward On the platform, compression flanges 2 are arranged on the upper sides of both ends of the combined retaining ring 4, and after the two ends of the installation assembly 3 are rested on the compression flanges 2 at both ends, the screws and nuts of the bolt assembly 8 connect the metal frame 1 and the Metal frame 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap