Modified nanocrystalline strip, preparation method and application thereof

A nanocrystalline strip and modification technology, applied in the field of materials, can solve problems such as uneven distribution of magnetic field, deterioration of magnetic shielding and magnetic conduction effect, serious eddy current loss of magnetic sheet, etc., to avoid concentration and uneven distribution of magnetic field, and to achieve good electric energy Transmission efficiency, effect of high power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

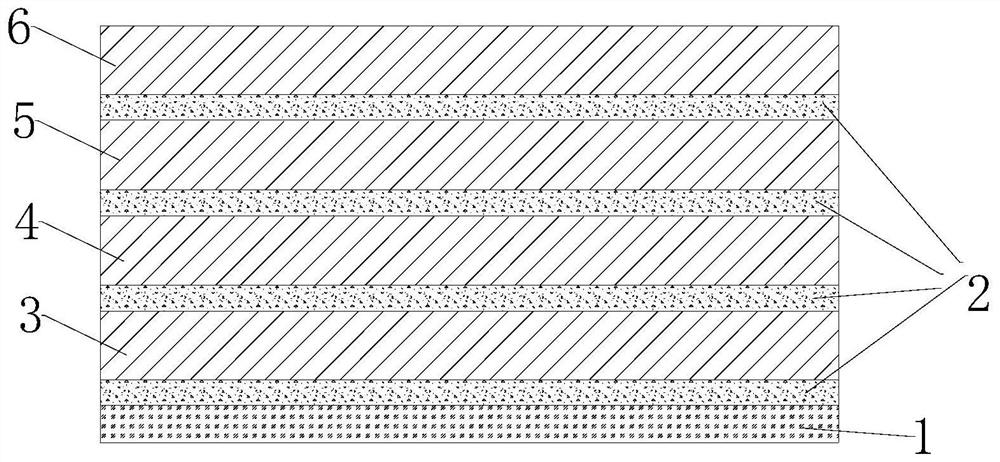

[0069] This embodiment provides a figure 1 The magnetic sheet with nanocrystalline composite structure shown includes a release film layer 1, a first modified nanocrystalline ribbon 3, a second modified nanocrystalline ribbon 4, and a third modified nanocrystalline ribbon 5, which are sequentially stacked. 6 with the fourth modified nanocrystalline ribbon.

[0070] The double-sided adhesive 2 of the first modified nanocrystalline strip 3 is connected to the release film layer 1; the double-sided adhesive 2 of the adjacent two layers of modified nanocrystalline strips is connected to the nanocrystalline strip; the double-sided adhesive 2 The thickness of the strip is 5 μm, and the thickness of each layer of modified nanocrystalline ribbon is 20 μm.

[0071] The first modified nanocrystalline ribbon 3, the second modified nanocrystalline ribbon 4, the third modified nanocrystalline ribbon 5 and the fourth modified nanocrystalline ribbon 6 are independently prepared by the follo...

Embodiment 2

[0092] This embodiment provides a figure 1 The magnetic sheet with nanocrystalline composite structure shown includes a release film layer 1, a first modified nanocrystalline ribbon 3, a second modified nanocrystalline ribbon 4, and a third modified nanocrystalline ribbon 5, which are sequentially stacked. 6 with the fourth modified nanocrystalline ribbon.

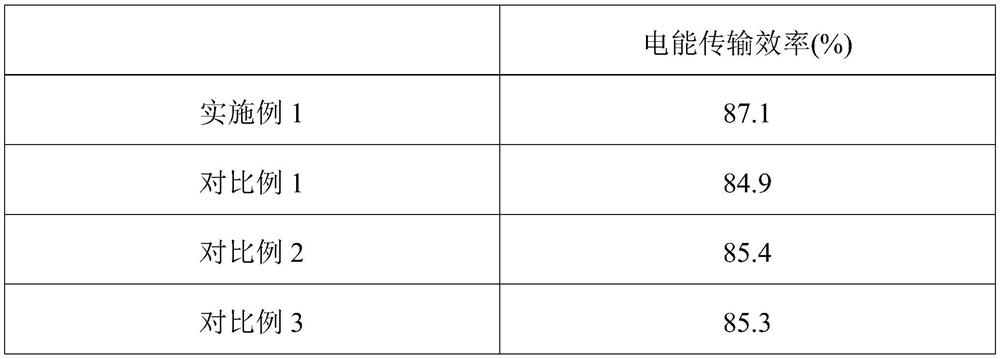

[0093] The real part of the magnetic permeability μ of the first modified nanocrystalline ribbon 3, the second modified nanocrystalline ribbon 4, the third modified nanocrystalline ribbon 5, and the fourth modified nanocrystalline ribbon 6 And the imaginary part of permeability μ`` are shown in the table below.

[0094] Permeability real part μ` Imaginary part of permeability μ`` The first modified nanocrystalline ribbon 492.6 38.9 The second modified nanocrystalline ribbon 758.2 55.7 The third modified nanocrystalline ribbon 1119.4 74.3 The fourth modified nanocrystalline ribbon 7...

Embodiment 3

[0113] This embodiment provides a figure 1 The magnetic sheet with nanocrystalline composite structure shown includes a release film layer 1, a first modified nanocrystalline ribbon 3, a second modified nanocrystalline ribbon 4, and a third modified nanocrystalline ribbon 5, which are sequentially stacked. 6 with the fourth modified nanocrystalline ribbon.

[0114] The double-sided adhesive 2 of the first modified nanocrystalline strip 3 is connected to the release film layer 1; the double-sided adhesive 2 of the adjacent two layers of modified nanocrystalline strips is connected to the nanocrystalline strip; the double-sided adhesive 2 The thickness of the strip is 5 μm, and the thickness of each layer of modified nanocrystalline ribbon is 20 μm.

[0115] The first modified nanocrystalline ribbon 3, the second modified nanocrystalline ribbon 4, the third modified nanocrystalline ribbon 5 and the fourth modified nanocrystalline ribbon 6 are independently prepared by the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com