High-temperature-resistant and radiation-resistant stepping motor

A stepper motor, radiation-resistant technology, applied in the field of electric motors, can solve the problems of large size and weight of stepper motors, limited working environment, restricted application, etc., and achieve the effects of light weight, small size and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

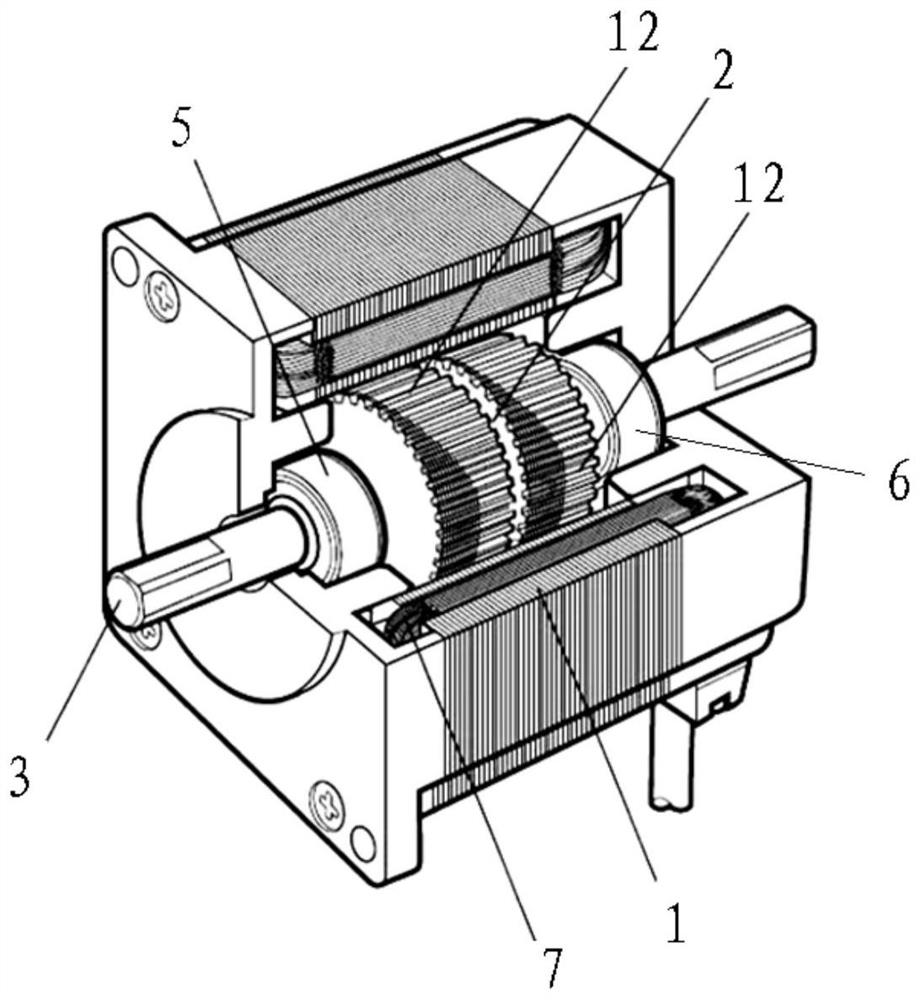

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

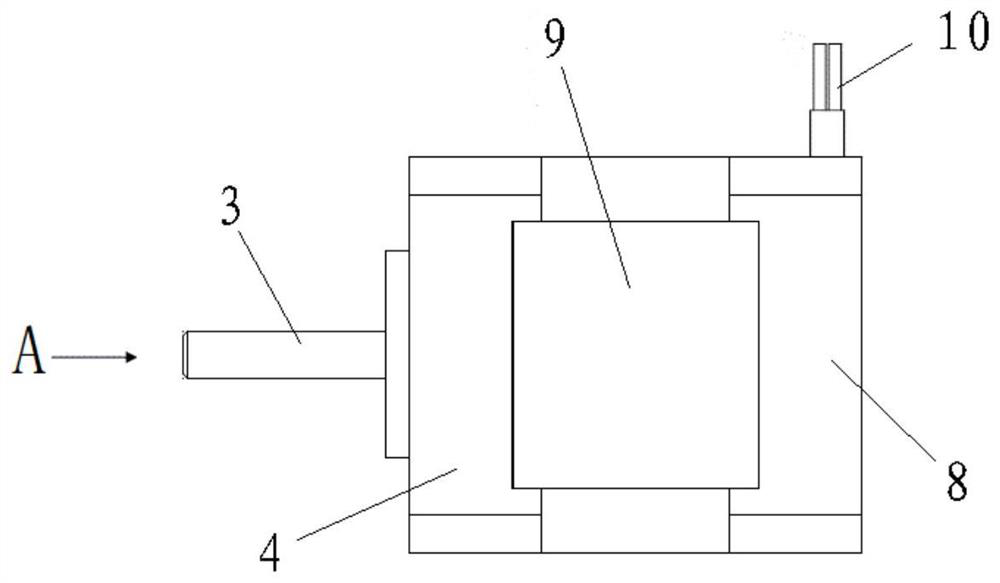

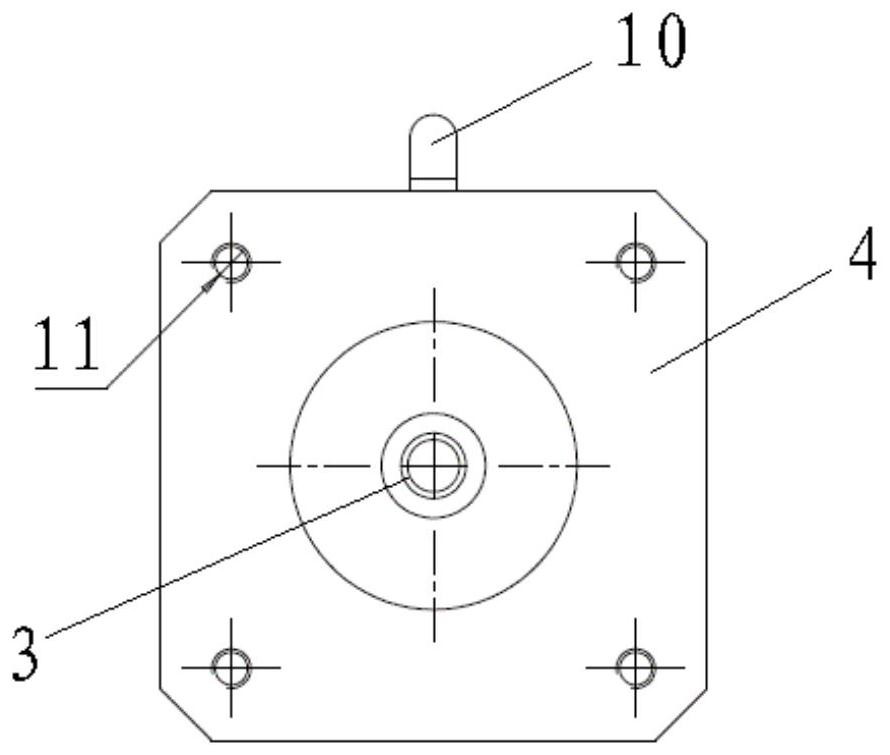

[0022] Such as Figure 1 to Figure 4 As shown, the present invention provides a high-temperature (200°C) radiation-resistant stepping motor, which includes a non-magnetic rotating shaft 3 with two rotors 12 connected in series, a stator 1 located at the periphery of the rotor 12, and a winding The winding coil 7 on the stator 1 is respectively arranged on the front end bearing 5 and the rear end bearing 6 at the front end and the rear end of the non-magnetic rotating shaft 3, the permanent magnetic steel 2 between the two rotors 12, and the permanent magnetic steel 2. The material is samarium cobalt magnet, the chemical composition is SmCo28, and the heat resistance temperature is 300 degrees.

[0023] The material of the rotor 12 and the stator 1 is silicon steel, and the heat-resistant temperature is greater than 300 degrees.

[0024] The material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com