Catalyst for preparing 1,4-cyclohexane dimethanol as well as preparation method and application thereof

A technology of cyclohexanedimethanol and dimethyl cyclohexanedicarboxylate is applied in the field of catalysts for preparing 1,4-cyclohexanedimethanol, can solve problems such as affecting yield and purity, and achieve yield and purity improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

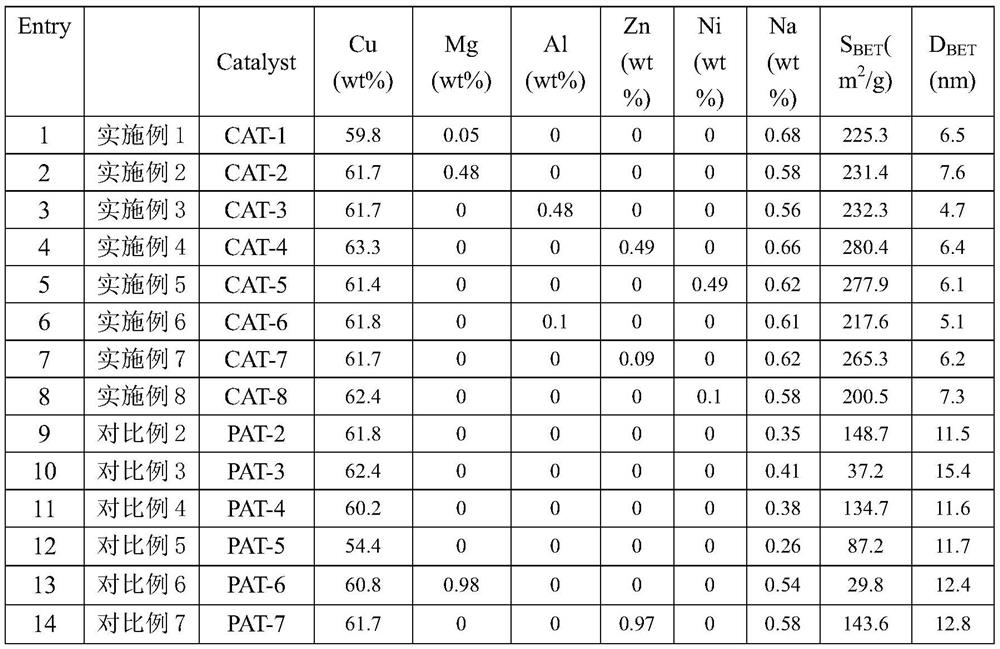

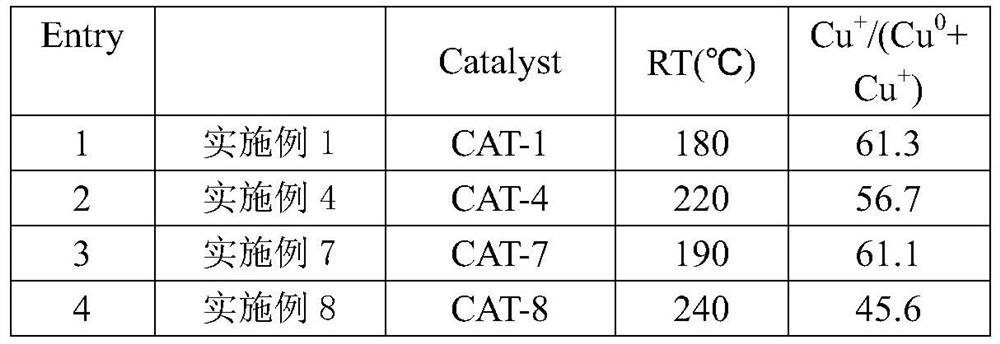

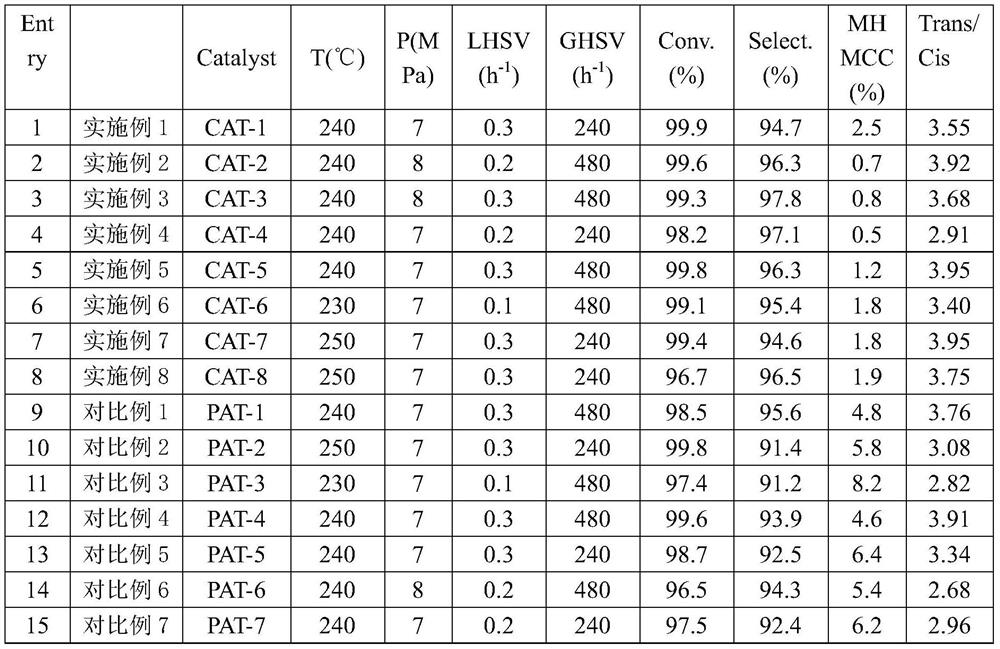

[0028] Example 1: A catalyst for preparing 1,4-cyclohexanedimethanol and a method for preparing 1,4-cyclohexanedimethanol

[0029] (1) The preparation method of catalyst:

[0030] S1. Weigh 56.1g of sodium bicarbonate and dissolve it in 504.9g of deionized water, stir and heat to 80°C at 500rpm / min;

[0031] S2. take again 34.6g tetraethyl orthosilicate and dissolve in 34.6g ethanol, drop in the sodium bicarbonate solution through the constant pressure dropping funnel;

[0032] S3. Weigh again 60.6g copper nitrate trihydrate and 0.19g magnesium nitrate hexahydrate and dissolve them in 242.4g deionized water together. The pH of the solution was 9.0, and the reaction was continued for 1 hour, and aged at 25°C for 12 hours.

[0033] S4. Take 1 L of deionized water for suction filtration and washing, and the precipitate after suction filtration is dried at 90° C. for 12 hours, and then calcined at 400° C. for 4 hours to obtain catalyst CAT-1.

[0034] (2) This catalyst is used ...

Embodiment 2

[0037] Example 2: A catalyst for preparing 1,4-cyclohexanedimethanol and a method for preparing 1,4-cyclohexanedimethanol

[0038] (1) The preparation method of catalyst:

[0039] S1. Weigh 56.1g of sodium bicarbonate and dissolve it in 504.9g of deionized water, stir and heat to 80°C at 500rpm / min;

[0040] S2. take again 34.6g tetraethyl orthosilicate and dissolve in 34.6g ethanol, drop in the sodium bicarbonate solution through the constant pressure dropping funnel;

[0041] S3. Weigh again 60.6g copper nitrate trihydrate and 1.9g magnesium nitrate hexahydrate and dissolve them in 242.4g deionized water together. The pH of the solution was 9.0, the reaction was continued for 1 hour, and then aged at 25°C for 2 hours.

[0042] S4. Take 1 L of deionized water for suction filtration and washing, and the precipitate after suction filtration is dried at 90° C. for 12 hours, and then calcined at 400° C. for 4 hours to obtain catalyst CAT-2.

[0043] (2) This catalyst is used f...

Embodiment 3

[0046] Example 3: A catalyst for preparing 1,4-cyclohexanedimethanol and a method for preparing 1,4-cyclohexanedimethanol

[0047] (1) The preparation method of catalyst:

[0048] S1. Weigh 56.1g of sodium bicarbonate and dissolve it in 504.9g of deionized water, stir and heat to 80°C at 500rpm / min;

[0049] S2. take again 34.6g tetraethyl orthosilicate and dissolve in 34.6g ethanol, drop in the sodium bicarbonate solution through the constant pressure dropping funnel;

[0050] S3. Weigh again 60.6g copper nitrate trihydrate and 1.1g aluminum nitrate nonahydrate and dissolve them in 242.4g deionized water together. The pH of the solution was 9.0, the reaction was continued for 1 hour, and then aged at 25°C for 2 hours.

[0051] S4. Take 1 L of deionized water and wash with suction, and the filtered precipitate is dried at 90° C. for 12 hours, and then calcined at 400° C. for 4 hours to obtain catalyst CAT-3.

[0052] (2) This catalyst is used for hydrogenation to prepare 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com