Negative plate, preparation method thereof and diaphragm-free battery cell

A negative electrode sheet, no diaphragm technology, applied in the direction of negative electrode, electrode manufacturing, electrode collector coating, etc., can solve the problems of poor bonding strength, affecting the air permeability of the negative electrode, etc., achieve good bonding, increase energy density, The effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

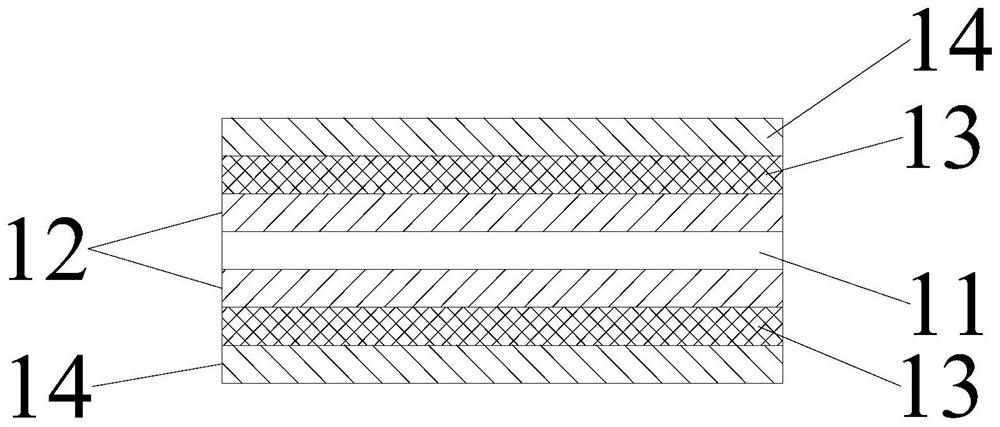

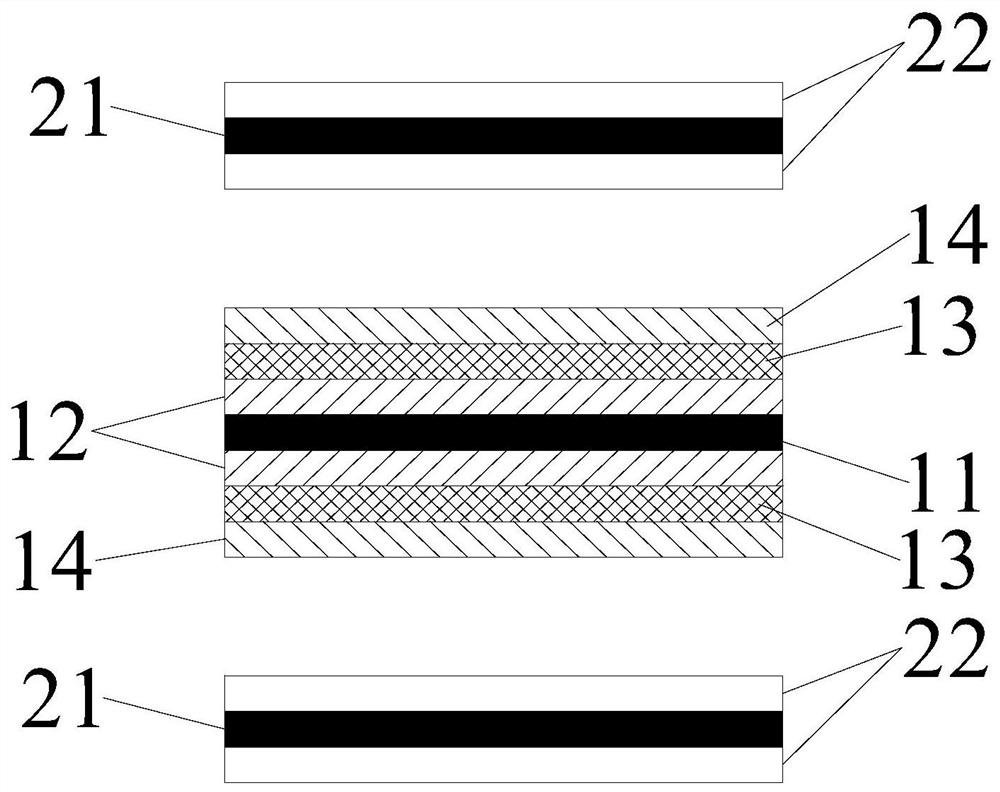

[0057] This embodiment provides a figure 1 As shown in the negative electrode sheet, the negative electrode sheet includes a negative electrode sheet current collector 11 and a negative electrode material layer 12 , an insulating ceramic layer 13 and a glue coating layer 14 sequentially arranged on both sides of the negative electrode sheet current collector 11 .

[0058] The thickness of the negative electrode material layer 12 is 120 μm, the thickness of the insulating ceramic layer 13 is 50 μm, and the thickness of the adhesive layer 14 is 15 μm.

[0059] The negative current collector is copper foil.

[0060] The preparation method of described negative plate comprises the following steps:

[0061] (1) Prepare the negative electrode active slurry, apply the negative electrode active slurry on both sides of the negative electrode current collector 11, and dry at 60°C to obtain the first negative electrode sheet;

[0062] The negative electrode active slurry includes: 60wt...

Embodiment 2

[0068] This embodiment provides a figure 1 The negative electrode sheet shown in step (2) is the same as that of Example 1 except that the mass percentage of the insulating ceramic material in the insulating slurry in step (2) is 15 wt%, and the mass percentage of the second binder is 30 wt%.

Embodiment 3

[0070] This embodiment provides a figure 1 The negative electrode sheet shown in step (2) is the same as that of Example 1 except that the mass percentage of the insulating ceramic material in the insulating slurry in step (2) is 5 wt%, and the mass percentage of the second binder is 75 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com