A kind of micro-nano composite silver-copper alloy solder paste for low-temperature sintering interconnection and preparation method thereof

A silver-copper alloy and low-temperature sintering technology, which is applied in the field of device packaging, can solve problems such as cracks in pure nano-solder paste, and achieve the effects of simple preparation methods, reduced costs, and delayed electrical/thermal migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

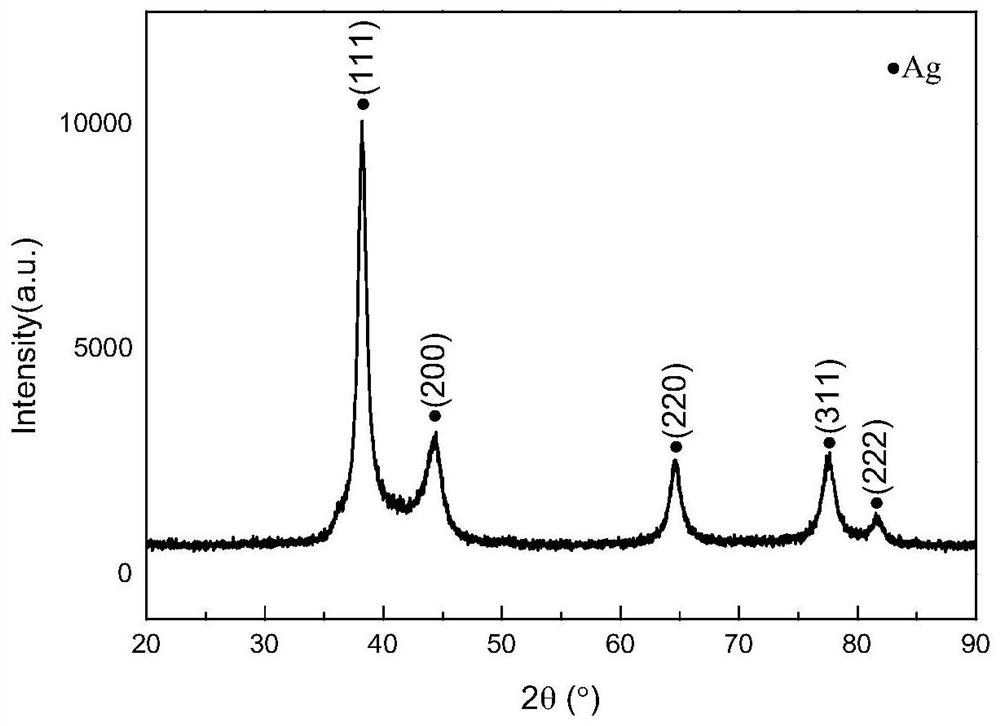

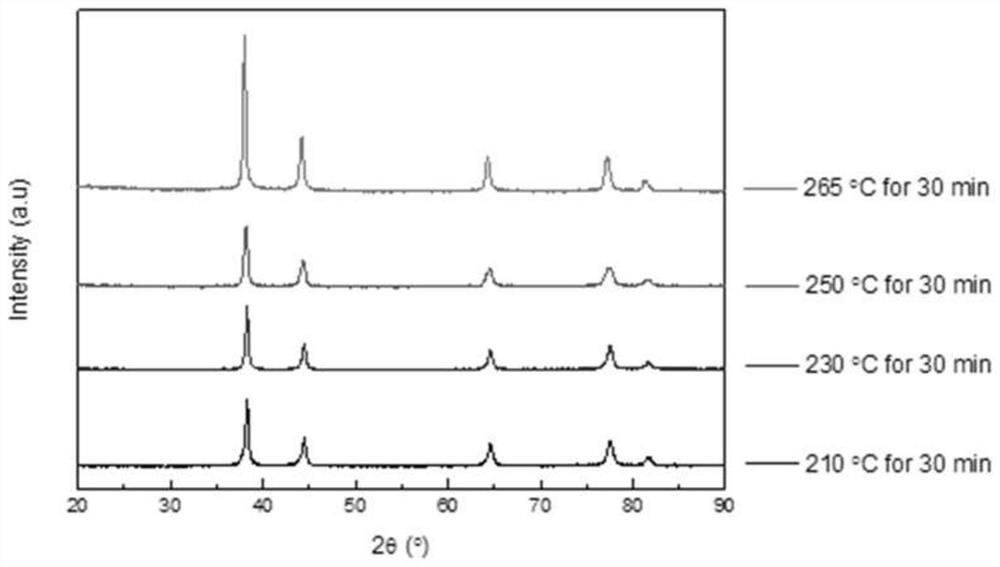

Image

Examples

Embodiment 1

[0037] A micro-nano composite silver-copper alloy solder paste for low-temperature sintering interconnection comprises nano-silver-copper alloy particles, micro-silver particles and an organic carrier. In terms of mass percentage, the nano-silver-copper alloy particles account for 50%, the micro-silver particles account for 20%, and the organic carrier accounts for 30%.

[0038] Step S1: the Cu(NO 3 ) 2 and AgNO 3 As a precursor, the silver-copper molar ratio in the preparation of nano-silver-copper alloy is 4:1, which is dissolved in deionized water according to a certain ratio, and is recorded as solution A;

[0039] Step S2: Dissolve polyvinylpyrrolidone with a molecular weight of 15,000 in deionized water, and the molar ratio of the polyvinylpyrrolidone to the precursor is 5:1, which is referred to as solution B.

[0040] Step S3: Dissolving sodium borohydride in deionized water, the concentration is 3 mol / L, and denoted as solution C.

[0041] Step S4: Pour the A solu...

Embodiment 2

[0048] A micro-nano composite silver-copper alloy solder paste for low-temperature sintering interconnection comprises nano-silver-copper alloy particles, micro-silver particles and an organic carrier. In terms of mass percentage, the nano-silver-copper alloy particles account for 65%, the micro-silver particles account for 10%, and the organic carrier accounts for 25%.

[0049] Step S1: the Cu(NO 3 ) 2 and AgNO 3 As a precursor, the silver-copper molar ratio in the preparation of nano-silver-copper alloy is 6:1, which is dissolved in deionized water according to a certain ratio, and is recorded as solution A;

[0050] Step S2: Dissolve polyvinylpyrrolidone with a molecular weight of 150,000 in deionized water, and the molar ratio of the polyvinylpyrrolidone to the precursor is 5:1, which is referred to as solution B.

[0051] Step S3: Dissolving sodium borohydride in deionized water, the concentration is 3 mol / L, and denoted as solution C.

[0052] Step S4: Pour the A sol...

Embodiment 3

[0058] A micro-nano composite silver-copper alloy solder paste for low-temperature sintering interconnection comprises nano-silver-copper alloy particles, micro-silver particles and an organic carrier. In terms of mass percentage, the nano-silver-copper alloy particles account for 70%, the micro-silver particles account for 18%, and the organic carrier accounts for 32%.

[0059] Step S1: the Cu(NO 3 ) 2 and AgNO 3 As a precursor, the silver-copper molar ratio in the preparation of nano-silver-copper alloy is 6:1, which is dissolved in deionized water according to a certain ratio, and is recorded as solution A;

[0060] Step S2: Dissolve sodium citrate in deionized water, and the molar ratio of the sodium citrate to the precursor is 10:1, denoted as solution B.

[0061] Step S3: Dissolving sodium borohydride in deionized water, the concentration is 3 mol / L, and denoted as solution C.

[0062] Step S4: Pour the A solution and the B solution into the container and mix them ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com