Flexible metal-based graphene electrothermal material and preparation method thereof

A technology of electrothermal materials and flexible metals, applied in the field of flexible metal-based graphene electrothermal materials and their preparation, can solve the problems of insufficient strength, limited application scenarios, and lack of ductility of copper foil to achieve high thermal conductivity and heat dissipation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

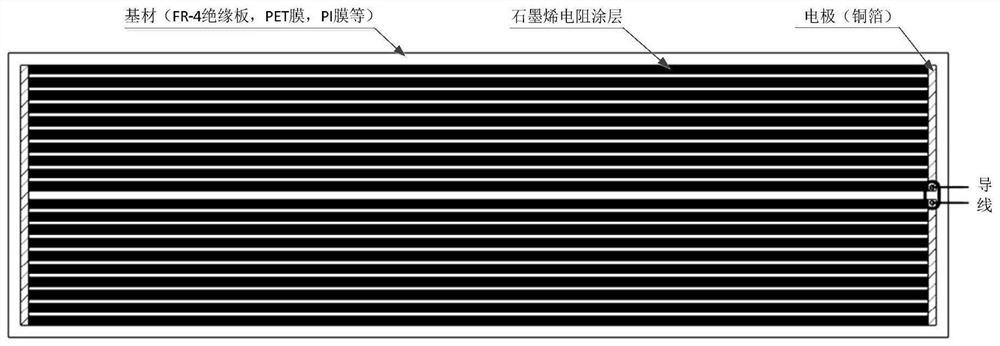

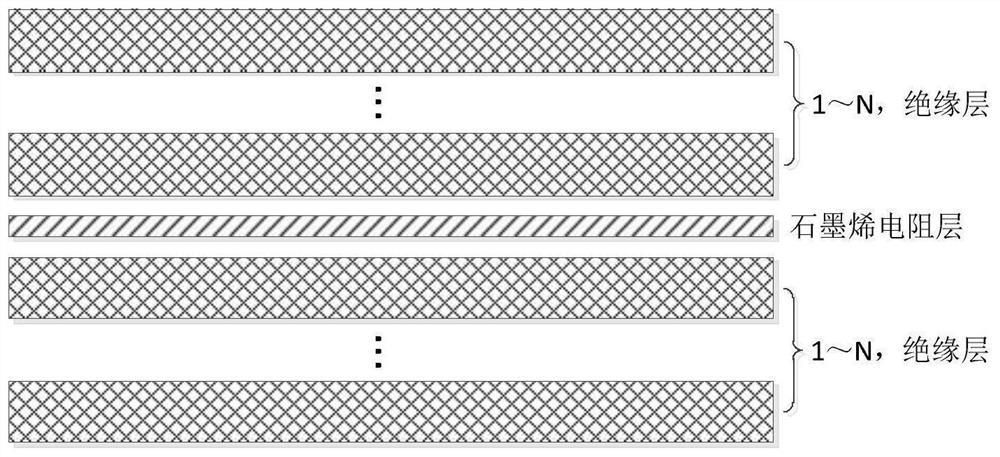

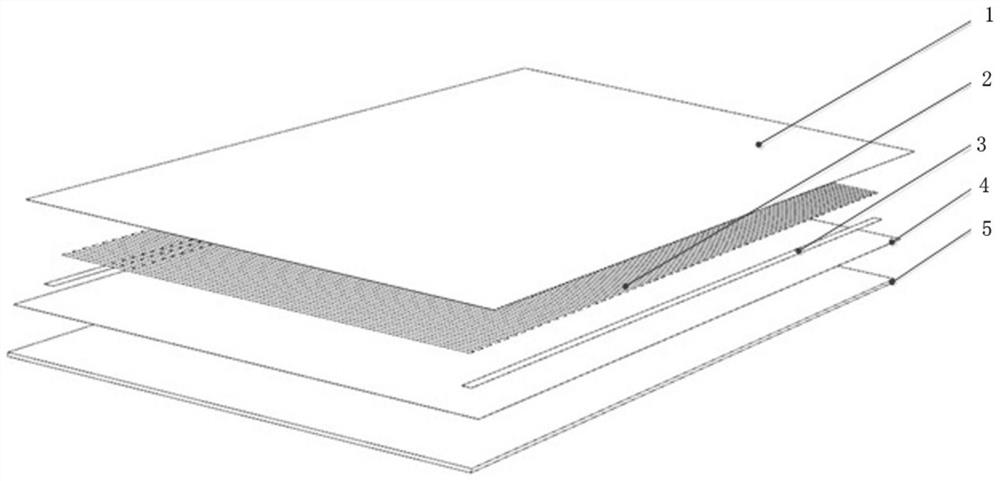

[0067] Embodiment one, such as image 3 As shown, a flexible metal-based graphene electrothermal material includes a flexible insulating layer 1, a flexible graphene resistance layer 2, a flexible insulating layer 4 and a metal substrate 5 arranged sequentially from top to bottom, and the flexible graphene A rolled copper foil 3 is also provided between the resistance layer 2 and the flexible insulating layer 4 .

[0068] Specifically, the rolled copper foil 3 is strip-shaped, at least two are provided, and there is a certain distance between the two rolled copper foils 3 .

[0069] In this embodiment, the flexible metal-based graphene electric heating plate is laminated by four kinds of materials, and then a functional electric heating material is formed by high temperature and high pressure in a vacuum environment. The formed functional electrothermal material has a flat state such as Figure 4 shown.

[0070] Wherein, the electrothermal material is a bendable flexible ma...

Embodiment 2

[0076] Embodiment 2, in order to prepare the flexible metal-based graphene electrothermal material in Embodiment 1, a specific FR-4 prepreg glue is configured, and the glue includes the following components in weight percentage:

[0077] Epoxy 52%,

[0078] Dicyandiamide 1%,

[0079] Dimethylimidazole 0.01%,

[0080] Dimethylformamide solvent 17%,

[0081] Silane coupling agent KH-560 0.15%,

[0082] SiO2 superfine silicon powder 25%,

[0083] Water 4.84%.

[0084] Among them, the CAS number of epoxy resin is 61788-97-4, the CAS number of dicyandiamide is 461-58-5, the CAS number of dimethylimidazole is 693-98-1, and the CAS number of dimethylformamide It is 68-12-2, the CAS number of silane coupling agent KH-560 is 2530-83-5-8, and the CAS number of SiO2 is 14808-60-7.

[0085] After the glue is formulated in the above formula, the glue is evenly coated on the 7628 glass fiber cloth by a vertical gluing machine, and dried to make a prepreg for subsequent lamination. Ot...

Embodiment 3

[0086] Embodiment 3, in order to prepare the flexible metal-based graphene electrothermal material in Embodiment 1, a specific FR-4 prepreg glue solution is configured, and the glue solution includes the following components by weight percentage:

[0087] epoxy resin 60%,

[0088] Dicyandiamide 1.5%,

[0089] Dimethylimidazole 0.05%,

[0090] Dimethylformamide solvent 18%,

[0091] Silane coupling agent KH-560 0.25%,

[0092] SiO2 superfine silicon powder 20.2%.

[0093] After the glue is formulated in the above formula, the glue is evenly coated on the 7628 glass fiber cloth by a vertical gluing machine, and dried to make a prepreg for subsequent lamination. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com