Matt plastic material and preparation method thereof

A plastic material, matte technology, applied in the field of polyurethane synthesis, can solve the problems of non-matte plastic products, eye damage to users, and bright surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

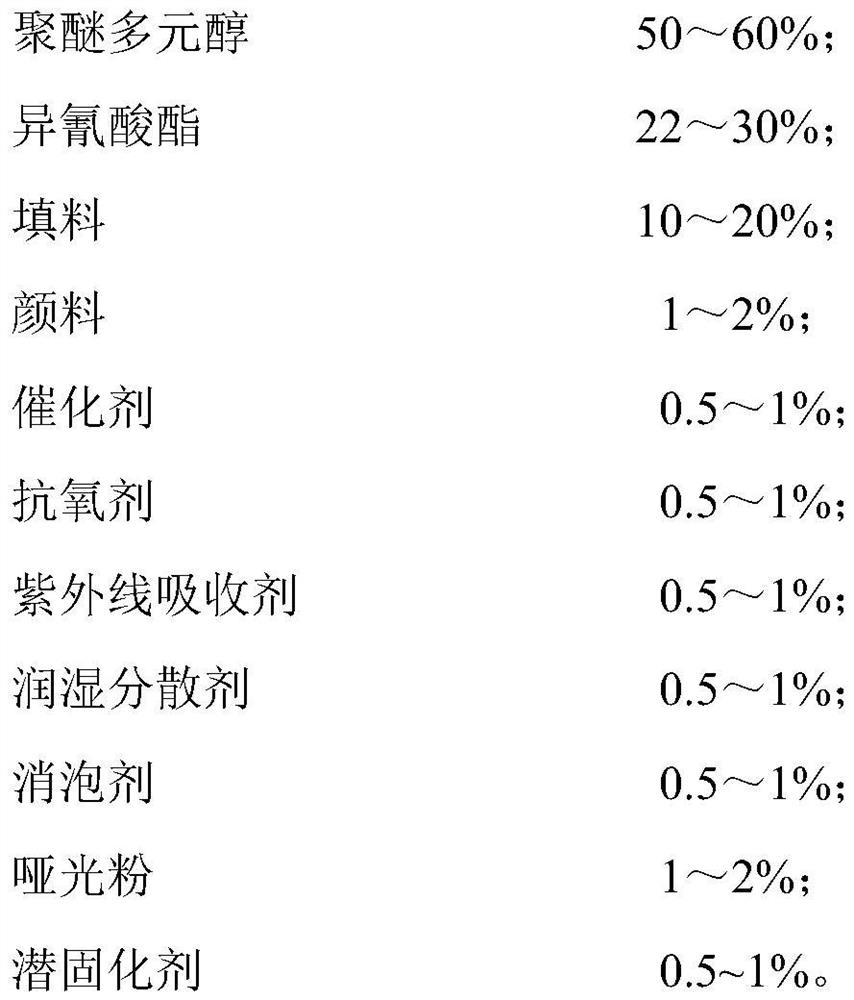

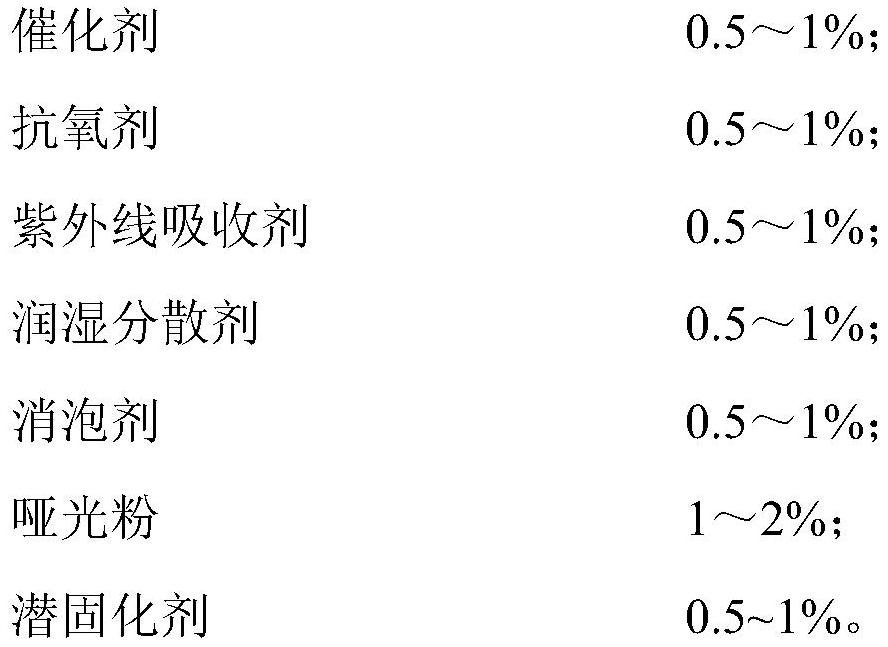

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 250g of polyether polyol DL-4000 and 250g of polyether polyol MN3050 into the flask, add 100g of 800 mesh talc powder, 20g of iron oxide green, 2,6-di-tert-butyl-4-methyl Base phenol 10g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 10g, heat up to 90°C, vacuum dehydrate for 4h to moisture 0.5‰, cool down to 30°C, add MDI-50300g, React at 85°C for 3 hours, cool down to 40°C, add BYK-W968 10g, CT-103 20g, VP0245 10g, ALT-10110g, BYK-066N 10g in sequence, stir for 30min, and pack into barrels to obtain the product;

[0029] (2) During construction, the matte plastic material can be spread directly on the foundation.

Embodiment 2

[0031] (1) Add 265g of polyether polyol DL-2000 and 265g of polyether polyol EP-330N into the flask, add 200g of 600 mesh talc powder, 10g of iron oxide red, 2,6-di-tert-butyl-4 -Methylphenol 5g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 5g, heat up to 100°C, vacuum dehydrate for 2h to moisture 0.8‰, cool down to 40°C, add MDI- 50220g, react at 90°C for 2h, cool down to 60°C, add BYK-W968 5g, CT-103 10g, VP0245 5g, ALT-1015g, BYK-066N 5g in sequence, stir for 40min, and pack into barrels to obtain the product;

[0032] (2) During construction, the matte plastic material can be spread directly on the foundation.

Embodiment 3

[0034] (1) Add 300g of polyether polyol DL-4000 and 300g of polyether polyol MN3050 into the flask, and then add 105g of 800 mesh talc powder, 15g of iron oxide green, 2,6-di-tert-butyl-4-methyl Base phenol 6g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 7g, heat up to 95°C, vacuum dehydrate for 3h to moisture 0.7‰, cool down to 35°C, add MDI-50225g, React at 88°C for 2.5h, cool down to 50°C, add BYK-W968 6g, CT-103 15g, VP0245 8g, ALT-1017g, BYK-066N 6g in turn, stir for 35min, and pack into barrels to obtain the product;

[0035] (2) During construction, the matte plastic material can be spread directly on the foundation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com