Waste plastic radiation thermal cracking process and system

A technology of waste plastics and radiant heat, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and the treatment of hydrocarbon oil, etc., which can solve the problems of high cost and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a waste plastic radiation thermal cracking process, comprising the following steps,

[0040]1) Preparation: Preliminary sorting of waste plastics: sort out iron wires and granular stones larger than 100mm and store them separately. 30mm material. The waste plastic is sent to the mixer 2 through a conveyor, and in the mixer 2, the waste plastic is fully mixed with the high-temperature slag 32 provided by the waste plastic pyrolysis machine 3, and the mixture of the two carries the waste heat of the high-temperature flue gas 31. The high-temperature flue gas 31 is the flue gas generated in the waste plastic pyrolysis machine 3, that is, the flue gas generated during the pyrolysis process of waste plastics. The flue gas has a high temperature and is suitable as a preheating heat source. Specifically, the waste plastic pyrolysis machine 3 can feed the high-temperature slag 32 into the mixer 2 through a quantitative dosing device, and control...

Embodiment 2

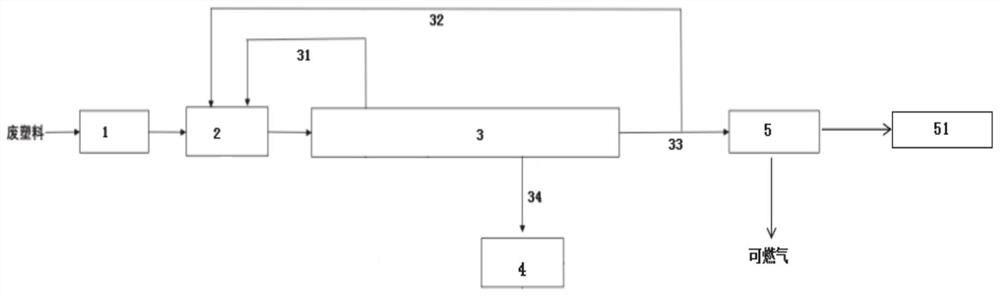

[0049] This embodiment provides a waste plastic radiative thermal cracking system, which can realize the waste plastic radiative thermal cracking process described in Embodiment 1.

[0050] It includes a crusher 1, a mixer 2, a waste plastic pyrolysis machine 3 and a dry material bin 4 connected in sequence. The connection method is carried out in accordance with the process sequence, that is, the waste plastics are first crushed, then mixed with the medium high-temperature slag 32 in the mixer and preheated, and then enter the waste plastic cracker for two-stage cracking, and finally the remaining qualified slag is 33 into the dry feed bin 4. Specifically, the crusher 1 is a two-stage crushing and tearing machine. The mixer 2 is a jacket structure, and the high-temperature flue gas passes through the jacket to heat the waste plastics.

[0051] There is a high-temperature slag conveying pipeline between the waste plastic pyrolyzer 3 and the mixer 2 . The high-temperature sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com