Test system and method for simulating muck improvement and migration

A technology of muck soil improvement and test system, which is applied in the fields of earth square drilling, soil material testing, material inspection products, etc., can solve the problems of few joint action test devices, difficulty in meeting test requirements, neglect of muck soil improvement, etc. Achieve good plastic flow, low internal friction, good viscous and soft consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

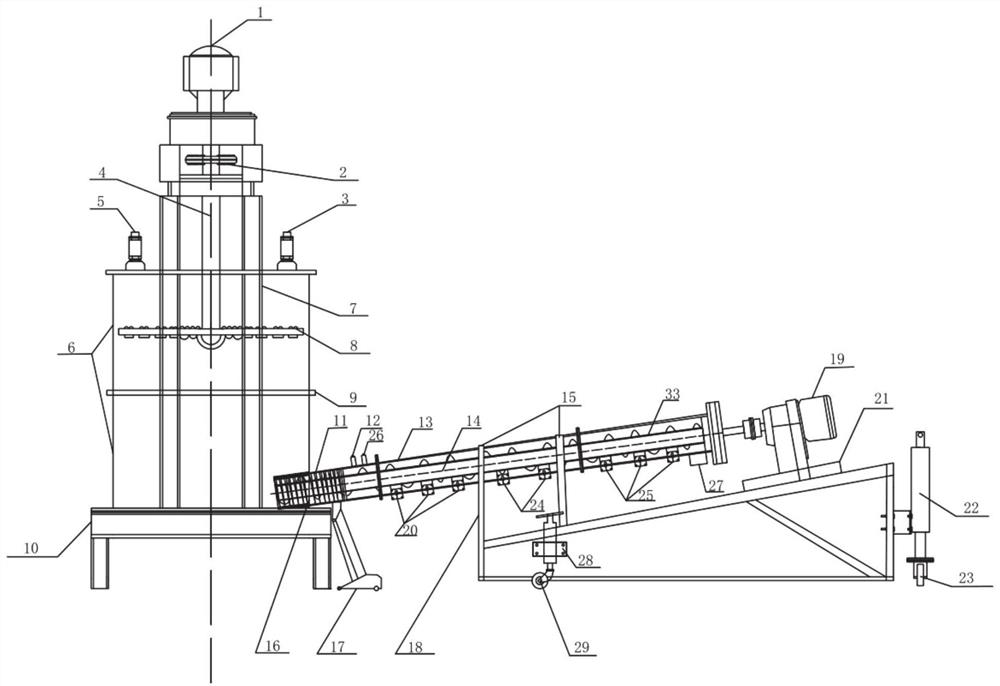

[0038] In a typical implementation of the present disclosure, as shown in the figure, a test system for simulating the improvement and movement of muck is proposed.

[0039] It mainly includes soil bin components, conveying components, support components and cutterhead components.

[0040]As a structure for accommodating the test soil, the soil bin assembly includes a soil bin 6 and a soil bin bracket 10. The soil bin is a shell structure with a cavity inside, which can accommodate the soil body and the improvement fluid. mixed space;

[0041] Specifically, such as figure 1 As shown, the soil bin is cylindrical as a whole, and the cutter head is installed inside the soil bin, arranged coaxially with the soil bin and capable of rotating around its axis. The driving mechanism of the cutter head is installed on the upper end surface of the soil bin, and the drive shaft of the 4 Connect the cutter head through the wall of the soil bin, and drive the cutter head to reciprocate al...

Embodiment 2

[0066] In another typical implementation of the present disclosure, such as Figure 1-Figure 5 As shown, a test method for simulating the movement of muck improvement is proposed.

[0067] Include the following steps:

[0068] Put the test soil into the soil bin, and inject the muck improvement solution into the soil bin;

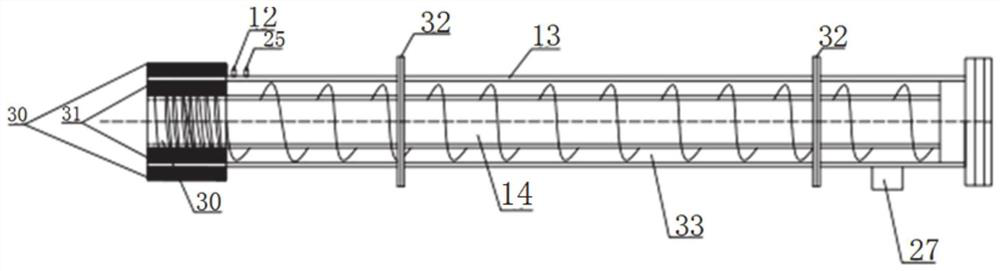

[0069] While the cutter head is rotating, it reciprocates along the axis of the soil bin to cut and mix the soil until the soil is evenly mixed with the improvement fluid;

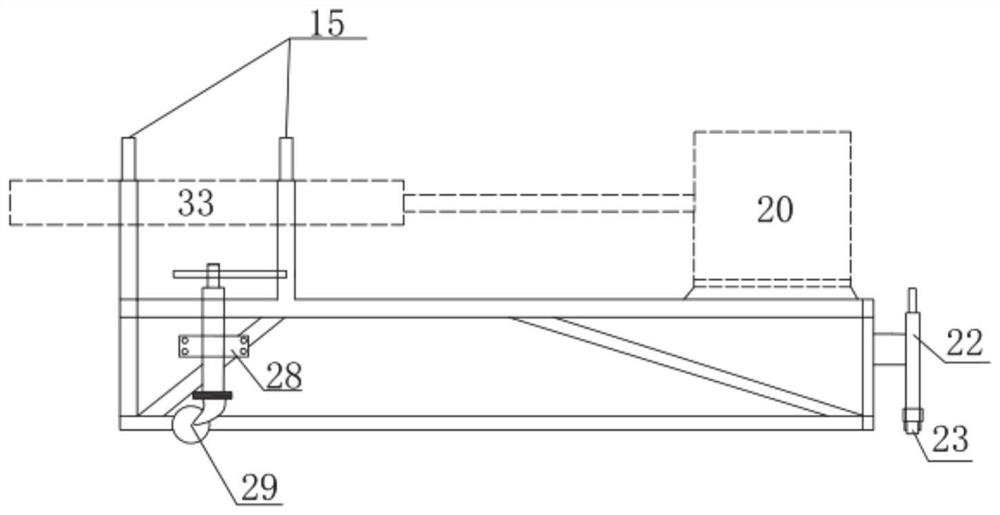

[0070] The cutter head moves axially to push the improved soil into the screw conveying mechanism, and the improved soil is discharged through the screw conveying mechanism;

[0071] The pressure sensor weighs different positions of the screw conveying mechanism, and obtains the internal pressure field of the screw conveying mechanism to adjust the operating state of the screw conveying mechanism.

[0072] Further, the screw conveying mechanism is connected with an improvement liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com