Heavy metal wastewater adsorbent and preparation method thereof

An adsorbent and heavy metal technology, applied in the field of heavy metal wastewater adsorbent and its preparation, can solve the problems of low adsorption capacity, low adsorption rate, long adsorption time of adsorbent, etc. The effect of heavy metal adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

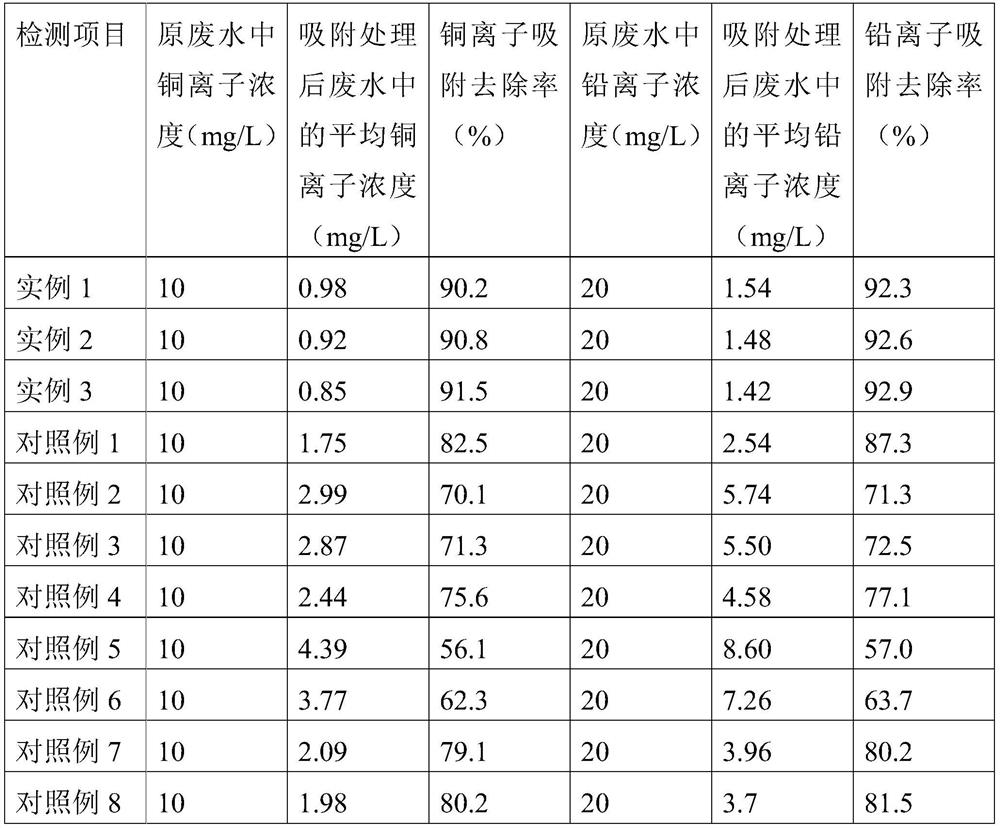

Examples

example 1

[0039] Weigh the rice straw and put it into the steam blasting tank, fill the blasting tank with water vapor at a temperature of 120°C until the pressure in the tank rises to 0.9MPa, seal the blasting tank, let it stand at constant temperature and pressure for 30 minutes, and then open it after standing The explosion tank releases water vapor to obtain steam explosion products;

[0040] In parts by weight, weigh 100 parts of the above steam explosion product and 3 parts of Lactobacillus, 1 part of Saccharopolyspora, 2 parts of Staphylococcus, 80 parts of deionized water and 8 parts of glucose, mix them evenly and put them into a fermenter , the sealed fermentation tank was left to ferment at 35°C for 3 days, and after the fermentation was completed, the filter residue was obtained by filtration, washed with deionized water for 3 times, and then dried to obtain modified straw fibers;

[0041] Mix polyvinyl alcohol and distilled water at a mass ratio of 1:10, heat up to 100°C, s...

example 2

[0045] Weigh the rice straw and put it into the steam blasting tank, fill the blasting tank with water vapor at a temperature of 125°C until the pressure in the tank rises to 1.0MPa, seal the blasting tank, let it stand at constant temperature and pressure for 32 minutes, and then open it after standing The explosion tank releases water vapor to obtain steam explosion products;

[0046] In parts by weight, weigh 105 parts of the above-mentioned steam explosion product and 3 parts of Lactobacillus, 1 part of Saccharopolyspora, 2 parts of Staphylococcus, 85 parts of deionized water and 8 parts of glucose and mix them evenly and put them into the fermenter , the sealed fermentation tank was left to ferment at 38°C for 3 days, and after the fermentation was completed, the filter residue was obtained by filtration and separation, washed with deionized water for 3 times, and then dried to obtain modified straw fibers;

[0047] Mix polyvinyl alcohol and distilled water at a mass rati...

example 3

[0051] Weigh the rice straw and put it into the steam blast tank, fill the blast tank with water vapor at a temperature of 140°C until the pressure in the tank rises to 1.2MPa, seal the blast tank, let it stand at constant temperature and pressure for 40 minutes, and then open it after standing The explosion tank releases water vapor to obtain steam explosion products;

[0052] In parts by weight, weigh 120 parts of the above-mentioned steam explosion product and 5 parts of Lactobacillus, 2 parts of Saccharopolyspora, 4 parts of Staphylococcus, 100 parts of deionized water and 10 parts of glucose and mix them evenly and put them into a fermenter , the sealed fermenter was left to ferment at 45°C for 5 days, and after the fermentation was completed, the filter residue was obtained by filtration and separation, washed with deionized water for 5 times, and then dried to obtain modified straw fibers;

[0053] Mix polyvinyl alcohol and distilled water at a mass ratio of 1:10, heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com