Bismuth ferrite/sepiolite composite visible-light-driven photocatalyst and preparation method thereof

A technology of sepiolite and bismuth ferrite, applied in the field of photocatalytic degradation of organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

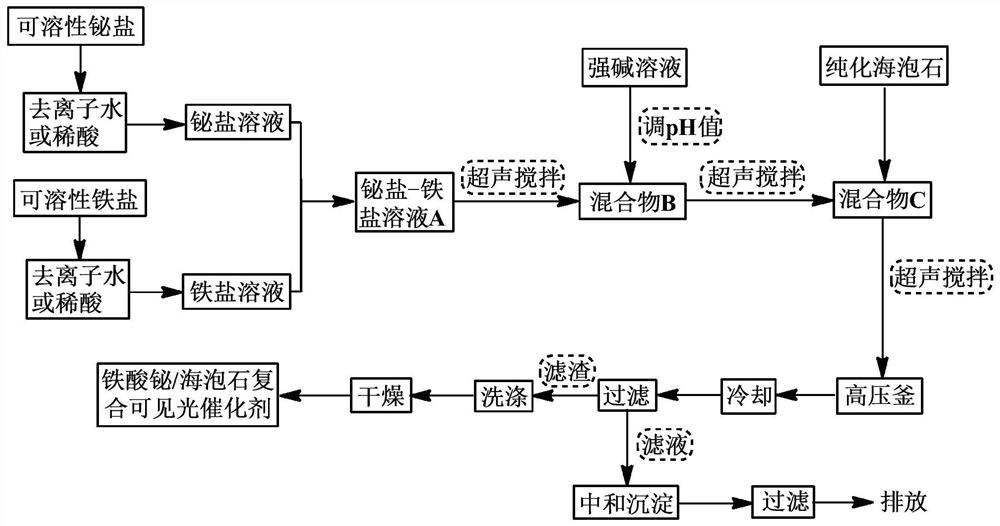

Method used

Image

Examples

Embodiment 1

[0033] (1) get 2.70g content and be that 99.0% bismuth nitrate pentahydrate is dissolved in 110mL deionized water to prepare Fe 3+ Concentration is 0.050mol / L solution, then take 2.26g ferric nitrate content is 98.5% and dissolve in 122mL deionized water to prepare Bi 3+ The concentration is 0.045mol / L solution; the two solutions are mixed, ultrasonically stirred for 2 hours, and bismuth nitrate-ferric nitrate solution A is obtained.

[0034] (2) Adjust the pH to 13.5 with 8 mol / L KOH solution, and continue ultrasonic stirring at room temperature for 2 hours to obtain mixture B;

[0035] (3) Add 0.27g of purified sepiolite to mixture B, and ultrasonically stir for 1.5h to obtain mixture C;

[0036] (4) Transfer the mixture C prepared in step (3) into a high-pressure reactor, and the reaction time at 200°C is 6h; cool to room temperature, filter, and wash the filter residue 3 times with deionized water and ethanol respectively, and heat it at 80°C After drying to constant wei...

Embodiment 2

[0039] (1) Get 2.70g of bismuth nitrate pentahydrate with a content of 99.0% and dissolve it in 100mL0.1mol / L dilute nitric acid to prepare Bi 3+ The concentration is 0.055mol / L solution, then take 2.21g ferric nitrate with a content of 98.5% and dissolve it in 108mL0.1mol / L dilute nitric acid to prepare Fe 3+ The concentration is 0.050 mol / L solution; the two solutions are mixed and ultrasonically stirred for 1.5 hours to obtain bismuth nitrate-ferric nitrate solution A.

[0040] (2) Use 8mol / L KOH solution to adjust the pH to 13.0, and continue ultrasonic stirring at room temperature for 1.5h to obtain mixture B;

[0041] (3) Add 0.22 g of purified sepiolite to mixture B, and ultrasonically stir for 1.5 h to obtain mixture C;

[0042] (4) Transfer the mixture C prepared in step (3) into a high-pressure reactor, and the reaction time is 7h at 190°C; cool to room temperature, filter, and wash the filter residue 4 times with deionized water and ethanol, and then wash it at 75°...

Embodiment 3

[0045] (1) 2.70g content of 99.0% bismuth nitrate pentahydrate was dissolved in 92mL deionized water to prepare Bi 3+ Concentration is 0.060mol / L solution, then take 2.21g ferric nitrate with content of 98.5% and dissolve it in 95mL deionized water to prepare Fe 3+ The concentration is 0.055mol / L solution; the two solutions are mixed and stirred ultrasonically for 1 hour to obtain bismuth nitrate-ferric nitrate solution A.

[0046] (2) Adjust the pH to 12.6 with 6mol / L KOH solution, and continue ultrasonic stirring at room temperature for 1 hour to obtain mixture B;

[0047] (3) Add 0.54 g of purified sepiolite to mixture B, and ultrasonically stir for 1 hour to obtain mixture C;

[0048] (4) Transfer the mixture C prepared in step (3) to a high-pressure reactor, and the reaction time is 8h at 180°C; cool to room temperature, filter, and wash the filter residue 4 times with deionized water and ethanol, Dry to constant weight to obtain 2.20 g of bismuth ferrite / sepiolite comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com