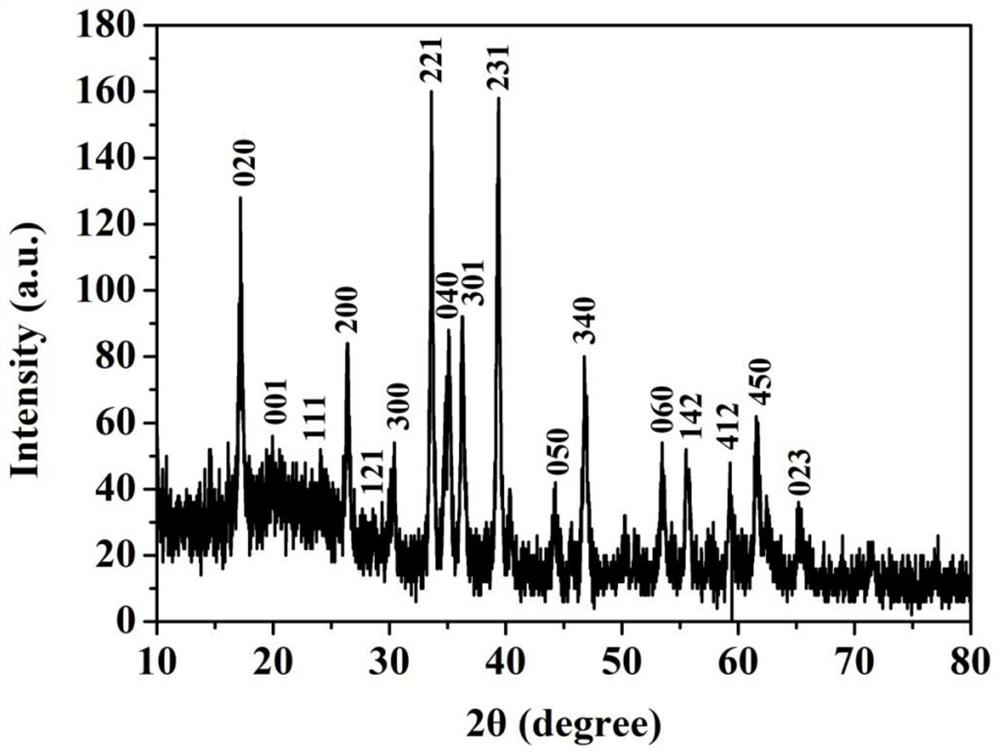

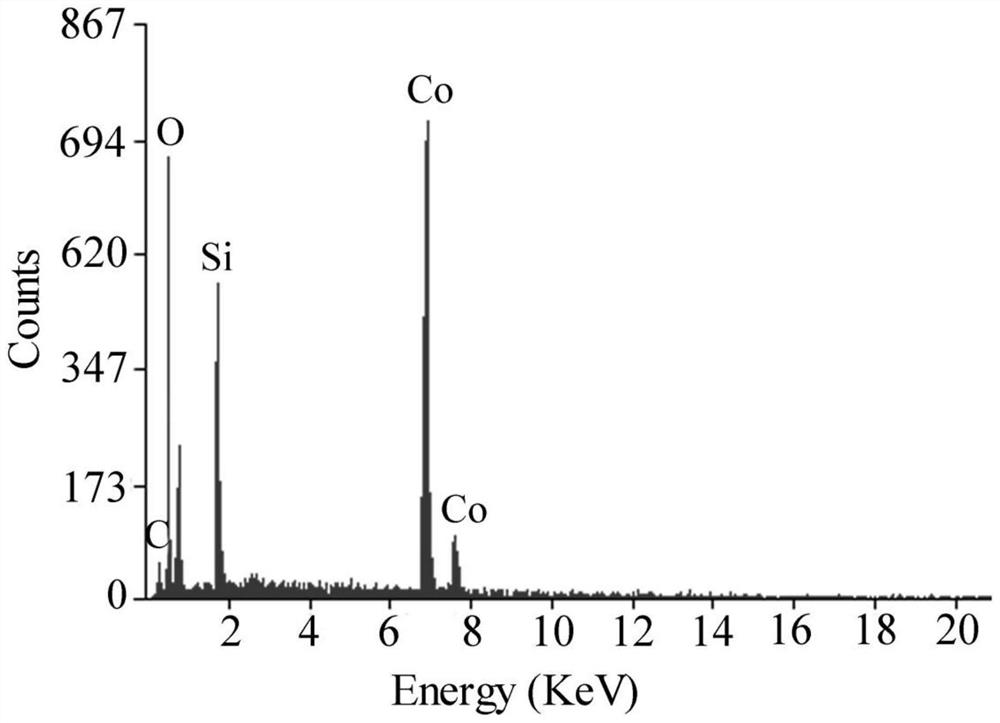

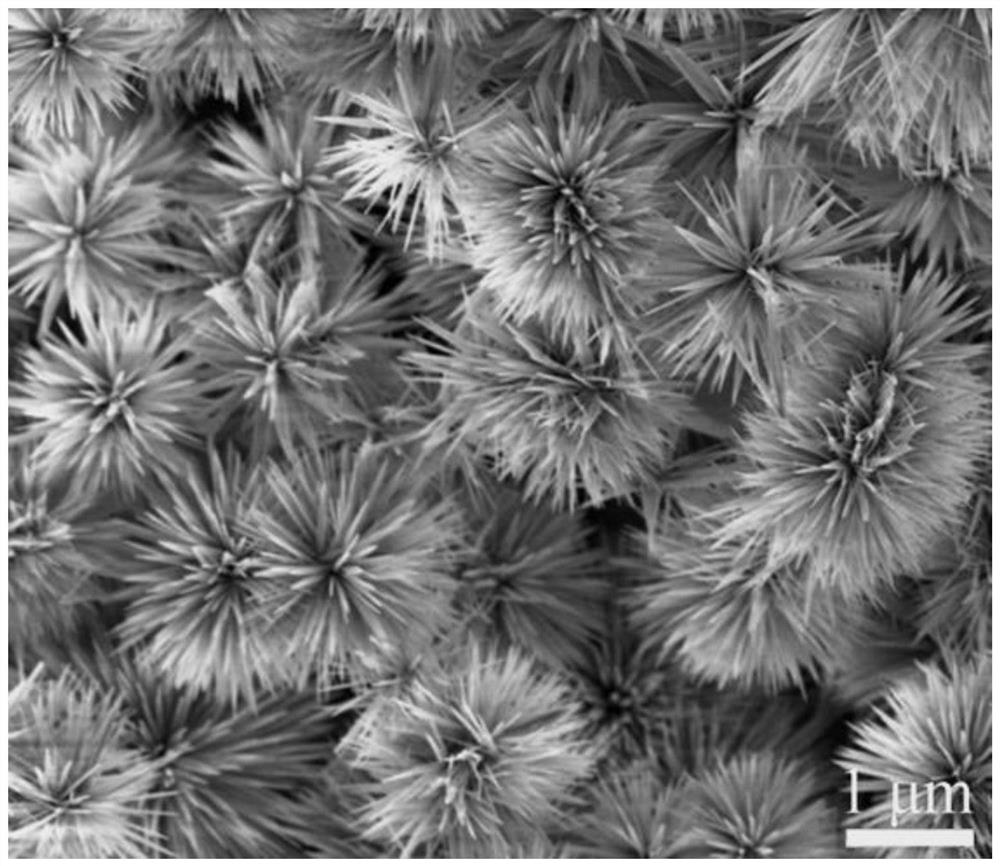

Preparation method of sea urchin-shaped basic cobalt carbonate

A technology of cobalt carbonate and sea urchin shape, which is applied in the field of preparation of sea urchin shape basic cobalt carbonate, which can solve the problems of large structure size, difficult size control, and low aggregation density of nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of sea urchin shape cobalt basic carbonate is characterized in that, carries out as follows:

[0030] Step (1) Dissolve cobalt nitrate hexahydrate in a mixture of deionized water and ethylene glycol to form solution A. The volume ratio of deionized water and ethylene glycol is 1:1, and the amount of cobalt nitrate hexahydrate in solution A The concentration is 0.1mol / L;

[0031] Step (2) Dissolve urea in a mixed solution of ammonia water and ethylene glycol with a mass fraction of 25% to form solution B. The volume ratio of ammonia water and ethylene glycol is 1:2, and the concentration of urea in solution B is 0.3mol / L;

[0032] Step (3) Heat solution A to 75°C, according to the molar ratio of cobalt nitrate hexahydrate and urea as 1:3, add solution B dropwise to solution A at a rate of 0.2 mL / min while stirring at 160 rpm;

[0033] After the step (4) is added dropwise, a solvothermal reaction is carried out at 170°C for 2 hours;

[003...

Embodiment 2

[0038] A kind of preparation method of sea urchin shape cobalt basic carbonate is characterized in that, carries out as follows:

[0039] Step (1) Dissolve cobalt nitrate hexahydrate in a mixture of deionized water and ethylene glycol to form solution A. The volume ratio of deionized water and ethylene glycol is 1:1, and the amount of cobalt nitrate hexahydrate in solution A The concentration is 0.02mol / L;

[0040] Step (2) Dissolve urea in a mixed solution of ammonia water and ethylene glycol with a mass fraction of 25% to form solution B. The volume ratio of ammonia water and ethylene glycol is 1:1, and the concentration of urea in solution B is 0.03mol / L;

[0041] Step (3) Heat solution A to 70°C, according to the molar ratio of cobalt nitrate hexahydrate and urea as 1:3, add solution B dropwise to solution A at a rate of 0.15mL / min while stirring at 150rpm;

[0042]After the step (4) is added dropwise, a solvothermal reaction is carried out at 160°C for 5 hours;

[004...

Embodiment 3

[0046] A kind of preparation method of sea urchin shape cobalt basic carbonate is characterized in that, carries out as follows:

[0047] Step (1) Dissolve cobalt nitrate hexahydrate in a mixture of deionized water and ethylene glycol to form solution A. The volume ratio of deionized water and ethylene glycol is 1:1, and the amount of cobalt nitrate hexahydrate in solution A The concentration is 0.3mol / L;

[0048] Step (2) Dissolve urea in a mixed solution of ammonia water and ethylene glycol with a mass fraction of 25% to form solution B. The volume ratio of ammonia water and ethylene glycol is 1: 3, and the concentration of urea in solution B is 0.5mol / L;

[0049] Step (3) Heat solution A to 80°C, according to the molar ratio of cobalt nitrate hexahydrate and urea as 1:3, add solution B dropwise to solution A at a rate of 0.45mL / min while stirring at 150~180rpm ;

[0050] After the step (4) is added dropwise, a solvothermal reaction is carried out at 180°C for 1 hour;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com