Polyurethane or polyurethane-urea aqueous dispersion, preparation method and application thereof

A polyurethane and dispersion technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve insufficient activation, reduce the mobility of polyurethane segments, affect initial viscosity, strength and heat resistance, etc. problems, to achieve the effect of improving hydrolysis resistance, good bond strength and heat resistance, and reducing hydrolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

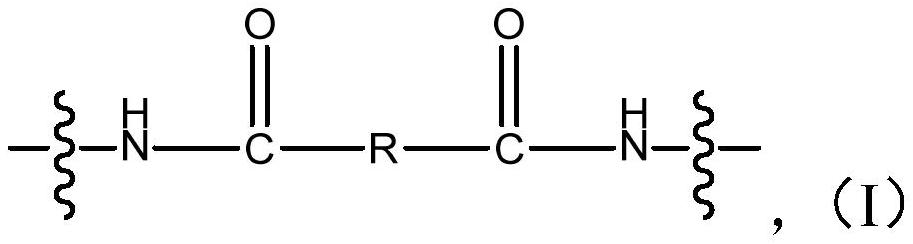

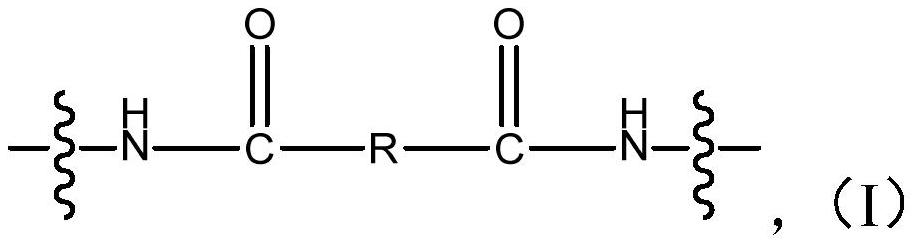

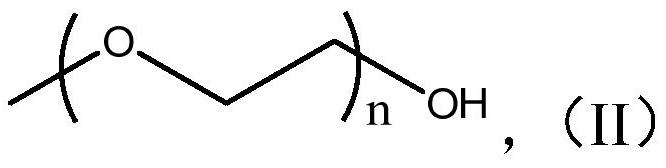

Method used

Image

Examples

Embodiment 1

[0109] 210g of polyester I, 29g of isocyanate I, 2g of polyether I, 24g of acetone, and 0.04g of bismuth neodecanoate are added to a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet through dehydration, at 80 The mixture was stirred at ~90°C until NCO reached 2.09%. The resulting prepolymer was dissolved in 400 g of acetone and cooled to 50°C. The 35g aqueous solution that will be dissolved with 4.63g N-(2-aminoethyl)-2-aminoethanesulfonate sodium, 2.47g N-aminoethylpiperazine, 1g hydroxyethyl ethylenediamine is added to the prepolymerized solution in acetone while stirring vigorously. After stirring for 20 min, the mixture was dispersed by adding 250 g of water. After the acetone had been separated off by distillation, 4 g of emulsifier Tween 20 were added. That is, a solvent-free polyurethane-polyurea aqueous dispersion having a solids content of 50% by weight and an average particle diameter in the dispersed phase of 180 nm measured by laser ...

Embodiment 2

[0111] Add 150g of dehydrated polyester I, 53g of dehydrated polyester II, 29g of isocyanate I, 24g of acetone, 0.04g of bismuth neodecanoate, and 2g of dehydrated polyether II into a 1L four- In a round bottom flask, the mixture was stirred at 80-90°C until the NCO reached 1.94%. The resulting prepolymer was dissolved in 380 g of acetone and cooled to 50°C. 30g aqueous solution with 2g N-(2-aminoethyl)-2-aminoethanesulfonate, 4g N,N-dimethyldipropylenetriamine, 1g hydroxyethylethylenediamine dissolved therein was added to the dissolved The acetone solution of the prepolymer was stirred vigorously. After stirring for 20 min, the mixture was dispersed by adding 210 g of water. After the acetone had been separated off by distillation, 4 g of emulsifier Tween 20 were added. That is, a solvent-free polyurethane-polyurea aqueous dispersion having a solids content of 55% by weight and an average particle diameter of 220 nm measured by laser correlation in the dispersed phase was ...

Embodiment 3

[0113] 80g of dehydrated polyester I, 33g of dehydrated polyester III, 23g of dehydrated polyester IV, 2g of dehydrated polyether I, 22g of isocyanate I, 18g of acetone, 0.04g of bismuth neodecanoate Add it into a 1L four-necked round-bottom flask equipped with a nitrogen inlet and outlet, and stir the mixture at 80-90° C. until NCO reaches 2.13%. The resulting prepolymer was dissolved in 309 g of acetone and cooled to 50°C. The 35g aqueous solution that will be dissolved with 4.6g N-(2-aminoethyl)-2-aminoethanesulfonate sodium, 1.5g N,N-dimethyldipropylene triamine, 1g hydroxyethyl ethylenediamine, is added to Dissolve the prepolymer in an acetone solution while stirring vigorously. After stirring for 20 min, the mixture was dispersed by adding 224 g of water. After the acetone had been separated off by distillation, 4 g of emulsifier Tween 20 were added. That is, a solvent-free polyurethane-polyurea aqueous dispersion having a solids content of 45% by weight and an averag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com