Polyvinyl alcohol casting solution, polyvinyl alcohol film and preparation method and application thereof

A technology of polyvinyl alcohol casting film and polyvinyl alcohol film, which is applied in the directions of instruments, polarizing elements, optical elements, etc., can solve the problems of high haze of PVA film, affecting light transmittance, affecting the use effect of PVA film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

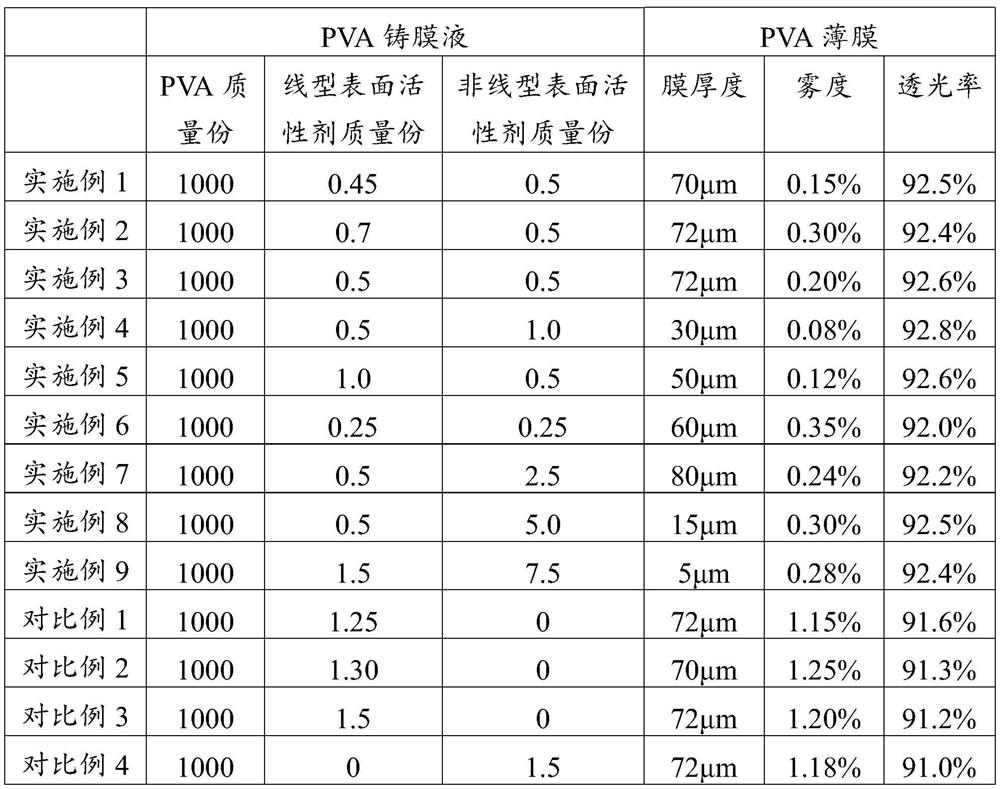

[0047] Based on the PVA film casting solution provided above, the present invention also proposes a specific example of a method for preparing a PVA film. The PVA film is prepared by conventional solution coating and casting method. In one embodiment of the preparation method of the PVA film provided by the present invention, the preparation method of the PVA film includes the following steps: drying the PVA film casting liquid to obtain a PVA film, and the PVA film casting liquid For the above-mentioned PVA film casting solution provided by the present invention, when the PVA film casting solution provided by the present invention is used to prepare the PVA film, the haze of the PVA film can be effectively controlled, and the surface tension of the film is reduced, and it is easy to peel off from the metal stick surface. Effect. Specifically, the PVA casting solution is extruded through a die and cast onto a roller or a steel belt, and then dried at high temperature or with h...

Embodiment 1

[0055] (1) The preparation method of PVA film casting solution: the PVA polymer (polymerization degree 1700, degree of alcoholysis 99.9%) of 1000 mass parts, the glycerin of 11 mass parts, the lauric acid diethanolamide (non-linear type) of 0.5 mass parts surfactant), 0.25 parts by mass of sodium lauryl polyoxyethylene ether sulfate (linear surfactant) and 0.2 parts by mass of sodium lauryl sulfate (linear surfactant), at 150 ° C ( High pressure) is dissolved in deionized water to form a PVA casting solution with a moisture content of 75wt%;

[0056] (2) Cool the PVA casting film stock solution prepared in step (1) to 95°C, discharge it through a 2m wide die, cast it onto a metal roller with a diameter of 2m, and dry the stock solution on the roller with 90°C hot air. film, and then through 11 sets of drying rollers, the front and back sides of the film are repeatedly dried in the range of 60-110 °C until the water content of the PVA film is 1-10 wt%, and a PVA film with an av...

Embodiment 2

[0059] (1) The preparation method of PVA film casting solution: the PVA polymer (polymerization degree 1700, degree of alcoholysis 99.9%) of 1000 mass parts, the glycerin of 11 mass parts, the lauric acid diethanolamide (non-linear type) of 0.5 mass parts surfactant), 0.5 parts by mass of sodium lauryl polyoxyethylene ether sulfate (linear surfactant) and 0.2 parts by mass of sodium lauryl sulfate (linear surfactant), at 150 ° C ( High pressure) is dissolved in deionized water to form a PVA casting solution with a moisture content of 75wt%;

[0060] (2) Cool the PVA casting film stock solution prepared in step (1) to 95°C, discharge it through a die with a width of 2m, cast it onto a metal roller with a diameter of 2m, and dry the stock solution on the roller with hot air at 90°C. film, and then through 11 sets of drying rollers, the front and back sides of the film are repeatedly dried in the range of 60-110°C until the water content of the PVA film is 1-10wt%, and a PVA film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com