Waste rubber powder modified asphalt for roads as well as preparation method and equipment thereof

A technology for modifying asphalt and waste rubber powder, applied in building components, building insulation materials, buildings, etc., can solve problems such as poor storage stability, poor aging resistance, and poor high temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of waste rubber powder modified asphalt for road, it is characterized in that, described modified asphalt comprises coupling agent, coupler and reinforcing agent, and described coupling agent is configured to increase the abrasion resistance of tire; The coupler is configured to impart stiffness to the tire; the reinforcing agent is configured to enhance interaction of the tire's rubber with carbon black.

[0033] The coupling agent includes the cis-1,4-polybutadiene product in the organic solvent solution polymerization reaction of 1,3-butadiene monomer, and a catalyst is added to the coupling agent, wherein the catalyst includes neodecyl At least one of neodymium octanoate, neodymium octanoate and neodymium vaseline.

[0034] Said coupler includes 1,4-polybutadiene elastomer, polyethylenediene elastomer, rubber-reinforced carbon black, precipitated silica and specified silica coupling agent, wherein, polyethylenediene The elastomer includes at le...

Embodiment 3

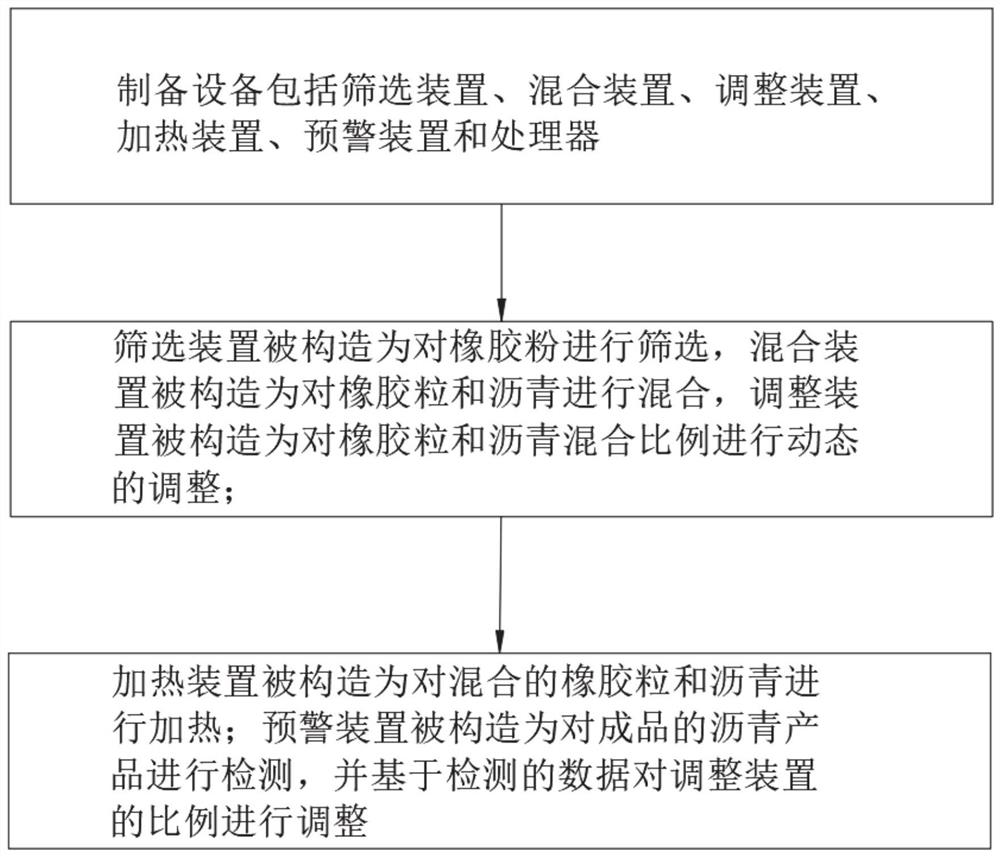

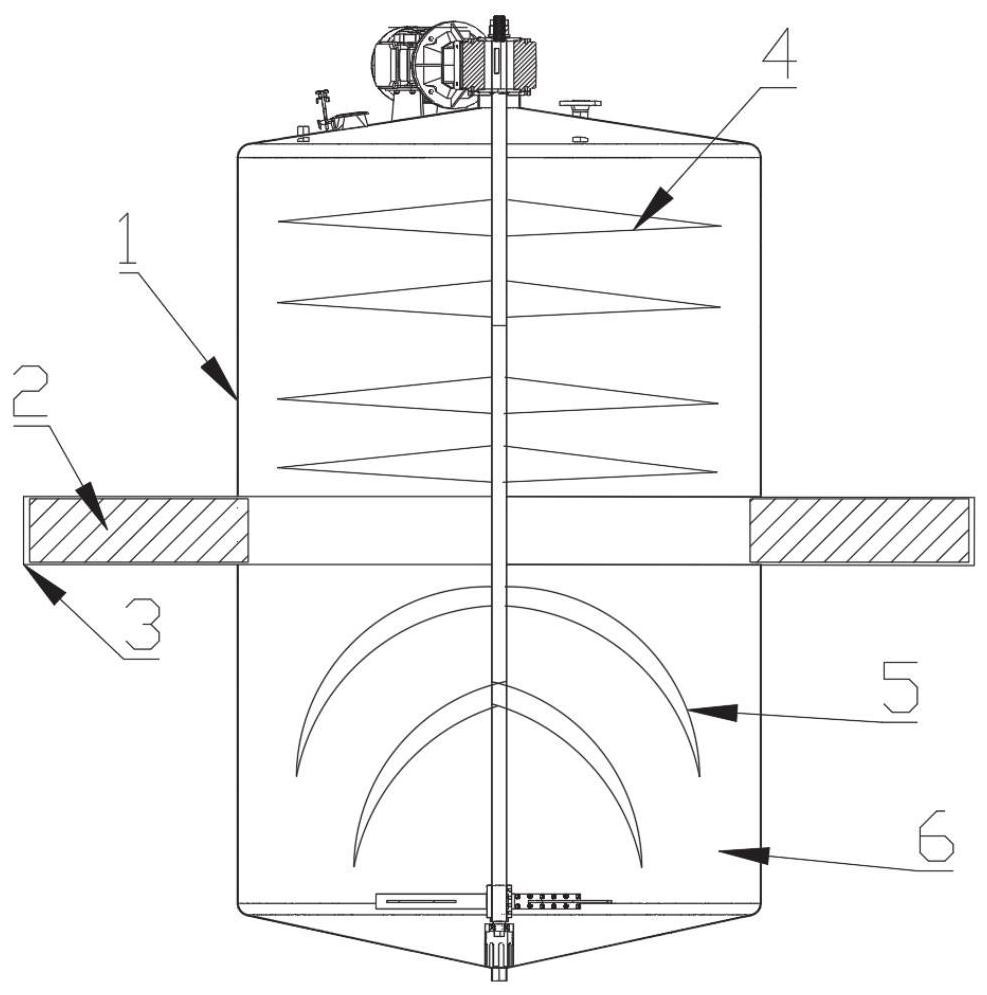

[0049] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the preceding embodiments, and further improvements are made on the basis of it. Specifically, a waste rubber powder modified asphalt for roads and its preparation method are provided, equipment, the preparation equipment includes a screening device, a mixing device, an adjustment device, a heating device, an early warning device and a processor, the screening device is configured to screen the rubber powder, and the mixing device is configured to screen the rubber powder The rubber granules and asphalt are mixed, and the adjustment device is configured to dynamically adjust the mixing ratio of the rubber granules and asphalt; the heating device is configured to heat the mixed rubber granules and asphalt; the early warning The device is configured to detect the finished asphalt product, and adjust the ratio of the adjusting device based on the detected data; specifical...

Embodiment 4

[0068] Embodiment 4: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, a waste rubber powder modified asphalt for roads and a preparation method thereof are provided. Raise the base asphalt lower than 170°C to about 190°C-210°C through the rapid heating device; measure the base asphalt through the asphalt flow meter, and then add it to the mixing device; after being weighed by the weighing device, the rubber powder is simultaneously transported to the mixing device in proportion device; rubber crumbs and base asphalt are mixed at a high speed in the mixing device through high-speed stirring and shearing; the uniformly stirred mixture is circulated into the mixing device through a special rubber asphalt pump; the mixture is stirred and kept warm (190°C) in the mixing device --210°C) and swell for about 2 to 6 hours, and the processing time can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com